Home » Mobile pump » Mobile pump unit specification

Mobile pump unit specification

Certainly, here is a sample specification for a mobile pump unit. Keep in mind that specifications will vary depending on the application, industry, and specific needs. This example covers some common aspects:

Contact US

Get Price

Share:

Previous:

Mobile pump unit requirements

Content

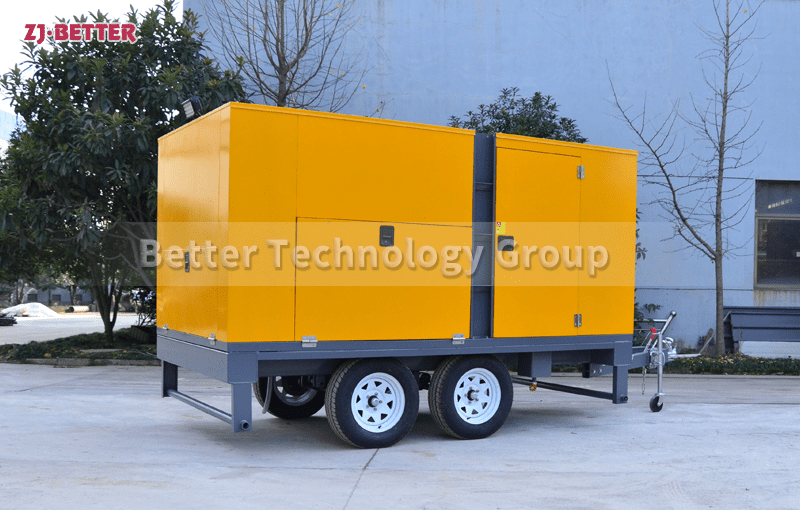

Mobile Pump Unit Specification

- Pump Type:

- Centrifugal Pump

- Flow Rate:

- Minimum: 500 gallons per minute (GPM)

- Maximum: 1500 GPM

- Head (Pressure):

- Minimum: 30 psi

- Maximum: 120 psi

- Power Source:

- Diesel Engine

- Horsepower: 50 HP

- Mobility:

- Trailer-Mounted

- Towing Hitch: 2-inch ball

- Construction:

- Pump Casing: Cast Iron

- Impeller: Stainless Steel

- Suction and Discharge Ports: 4-inch NPT

- Fluid Compatibility:

- Designed for water and non-corrosive fluids

- Controls and Instrumentation:

- On/Off Switch

- Throttle Control

- Pressure Gauge

- Engine Temperature Gauge

- Emergency Stop Button

- Safety Features:

- Pressure Relief Valve

- Low Oil Pressure Shutdown

- Overheating Protection

- Maintenance and Accessibility:

- Quick access panels for maintenance

- Easily replaceable filters and belts

- Environmental Considerations:

- Meets EPA emissions standards for diesel engines

- Noise Level: Below 85 dB at 10 feet

- Weather Resistance:

- Weatherproof housing for electronics and controls

- Corrosion-resistant coatings on exposed metal parts

- Transport and Storage:

- Dimensions (LxWxH): 10 ft x 6 ft x 7 ft

- Tie-down points for secure transportation

- Lockable storage compartments for hoses and accessories

- Additional Features:

- Self-priming capability for easy startup

- Fuel-efficient engine design

- Automatic shutdown in case of low oil or high temperature

- Budget:

- Cost not to exceed $20,000

- Application:

- Irrigation support for agricultural fields

- Emergency firefighting in rural areas

Please note that this is just a sample specification, and actual requirements may vary significantly depending on your specific needs. It’s crucial to tailor the specification to your application, consult with experts, and consider any industry-specific regulations or standards that apply.

Inquiry

More Mobile pump