Oil Pumps Made By Better

The oil pump is a light and compact pump, and there are three categories of in-line, distribution and single. The oil pump needs a power source to run, and the lower camshaft is driven by the engine crankshaft gear.

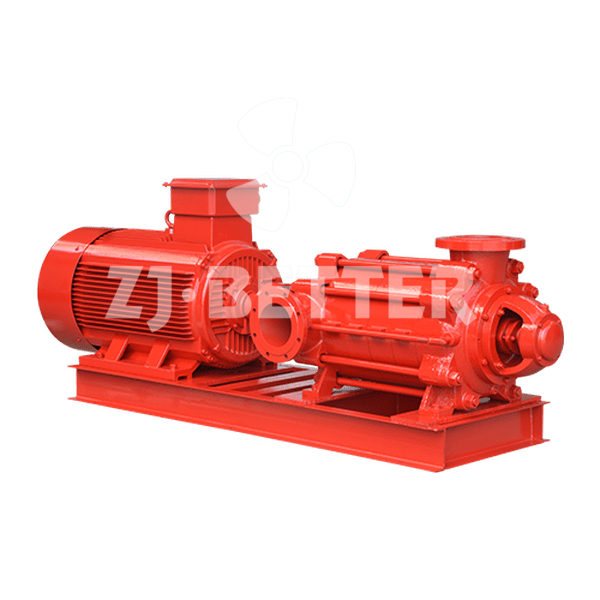

Centrifugal oil pumps are produced and used according to a certain process and according to a certain working principle to ensure that they play an important role and value in use. The self-priming centrifugal oil pump has unique structural features and structure. The impeller is installed in the pump casing and fastened to the pump shaft. The pump shaft is directly driven by the motor. The pump shaft and the impeller are used in cooperation with each other, and they fully display their own specialties and characteristics in use. There is a liquid suction in the center of the pump casing connected with the suction pipe to transmit the liquid during use. The liquid enters the pump through the bottom valve 6 and the suction pipe. The liquid discharge port on the pump casing is connected with the discharge pipe. The opening and closing of the centrifugal oil pump needs to pay attention to many matters to ensure that the implementation and work are carried out according to a certain method in use. Before the centrifugal oil pump starts, the pump casing is filled with the liquid to be conveyed; after starting, the impeller is driven by the shaft to roll at a high speed, and the liquid between the blades must also roll with it. Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and obtains energy, leaving the outer edge of the impeller at a high speed and entering the volute pump casing.