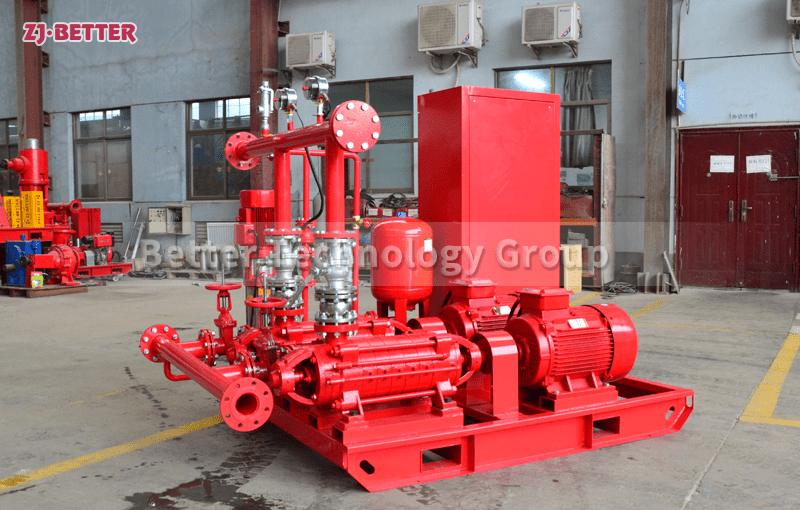

Outdoor fire pump sets without building pumping stations

Diesel engine fire pump is mainly composed of diesel engine, fire pump, coupling, fuel tank, radiator, battery pack, intelligent automatic control panel, etc. The company’s products are designed and optimized by computer. Our company has strong technical force, rich production experience and perfect testing methods to ensure the stability and reliability of product quality. The diesel engine fire pump adopts international advanced technology, sliding bearing, plate-fin air cooler, upper heat exchanger, spin-on oil filter and dual cooling system. The smoke and noise indicators reach the national high-quality product, and the fuel consumption is lower than the national standard high-quality product of 2.1g/kW.h.

Diesel engine fire pumps have been widely used in fire diversion as fixed fire fighting equipment, especially in the case of sudden fire water supply such as lack of power supply or abnormal power supply. , fire pump, connecting device, fuel tank, radiator, battery pack, intelligent automatic control screen, etc. Diesel engine fire pump products have the characteristics of leading technology, high degree of automation, excellent performance protection function, reasonable structure, simple installation and high cost performance. At the same time, in order to meet the different needs of users and reasonable investment, the products are divided into multiple application series such as fire pumps, industrial emergency pumps, agricultural pumps, marine pumps, trailer-type mobile water pump stations, etc., which can be used together with electric fire pumps.