Performance characteristics of diesel engine fire pump set

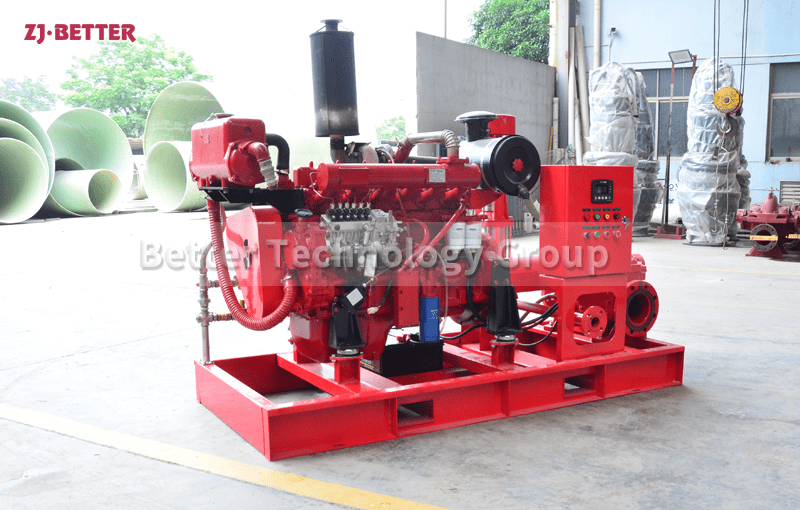

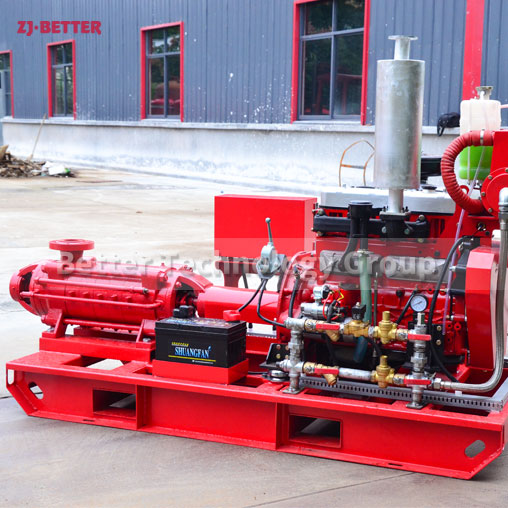

Now the general diesel engine fire pump set is powered by imported or domestic Cummins, Wuxi Power Engine Factory and other diesel engines produced by large-scale key enterprises in the internal combustion engine industry at home and abroad, through highly elastic couplings or diaphragm couplings produced by professional manufacturers. The engine is directly connected with the water pump, and the power of the diesel engine can reach 880KW. It can be equipped with water pumps of different lifts and flow rates for customers to choose and use according to different needs.

The diesel engine fire pump set has the characteristics of good starting characteristics, strong overload capacity, compact and reasonable structure, convenient maintenance, simple and reliable use, etc. The unit is equipped with protection functions such as overspeed, low oil pressure, three start failures, high water temperature, low oil level, and low battery voltage. At the same time, it can be connected with the customer’s automatic fire alarm device or the fire control system control cabinet produced by our factory to realize the function of remote monitoring.

Performance characteristics of diesel engine fire pump set:

一. The diesel engine fire pump set has three perfect starting functions:

1. Manual start function: manual and automatic interlocking can be completed through the transfer switch and manual start function can be realized;

2. Automatic and manual function: three starts are allowed, and if the three starts are unsuccessful, a “start failure alarm” will be issued and the start state will be automatically exited; after a successful start, the time to start to rated load is 5-10-15S (depending on the capacity of the unit) );

3. Emergency manual direct start function: when the automatic control device fails, the emergency manual direct start function can be realized.

二. Automatic operation: When the water pump unit receives an effective fire signal, if the motor fire pump power supply system is powered off or lacks phase or the electric pump fails to start normally, the diesel engine fire pump unit will automatically start and run. Once the power supply system returns to normal or When the electric pump is running normally, it can automatically switch to the electric pump.

三. Automatic shutdown: When the fire signal disappears, the diesel engine fire pump will stop automatically.

四. Battery self-charging and voltage stabilization function: the battery can be automatically charged by the mains power diesel engine charging motor to ensure the smooth start of the unit.