Performance Testing and Validation Methods for EJ Dual-Power Fire Pump Sets

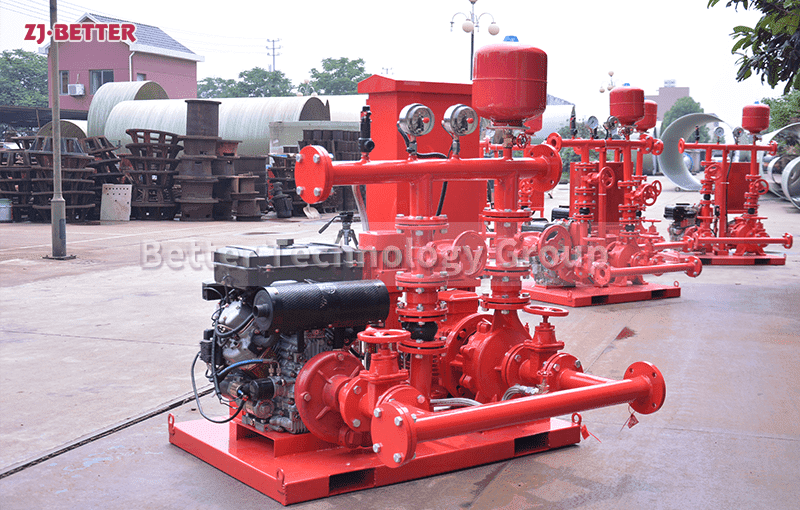

The EJ (Electric pump + Jockey pump) Dual Power Fire Pump System is an innovative and reliable fire protection solution. Combining an electric pump for robust water pressure and flow with a top-quality jockey pump for stable pressure maintenance, this system ensures efficient and timely water supply during fires. With advanced automation, remote monitoring, and energy-saving features, the EJ Dual Power Fire Pump System is a trusted choice for commercial, industrial, and residential applications.

- Dual Power Design: The EJ Fire Pump System incorporates both an electric pump and a jockey pump, ensuring a steady water pressure and flow during fire incidents.

- High Performance: The electric pump delivers powerful water pressure and flow, guaranteeing prompt water supply during fire emergencies. The jockey pump maintains stable pressure within the system, ensuring the reliability of the fire protection system.

- Intelligent Control: Equipped with an intelligent control system, the EJ Fire Pump System automatically monitors and adjusts the pump’s operation, ensuring optimal performance. This enhances system reliability and provides ease of operation.

- Remote Monitoring and Control: The EJ Fire Pump System allows for remote monitoring and control, enabling users to monitor the system’s operation and make necessary adjustments from a remote location.

- Energy Efficiency: The EJ Fire Pump System incorporates advanced energy-saving technologies, reducing energy consumption and operating costs.

- Reliability and Durability: Built with high-quality materials and advanced manufacturing processes, the EJ Fire Pump System offers excellent reliability and durability, ensuring long-term stable operation.

In summary, the EJ Fire Pump System stands out for its high-performance capabilities, intelligent control features, remote monitoring and control capabilities, energy efficiency, and overall reliability and durability. It is an ideal choice for fire protection needs.