Petrochemical Process Pump

Petrochemical process pumps are suitable for conveying clean or liquids containing a small amount of particles, low temperature or high temperature liquids, neutral or corrosive liquids. Suitable for oil refining, petrochemical, coal processing and cryogenic engineering, papermaking, metallurgy, medicine, synthetic fiber, power generation, environmental protection, etc.

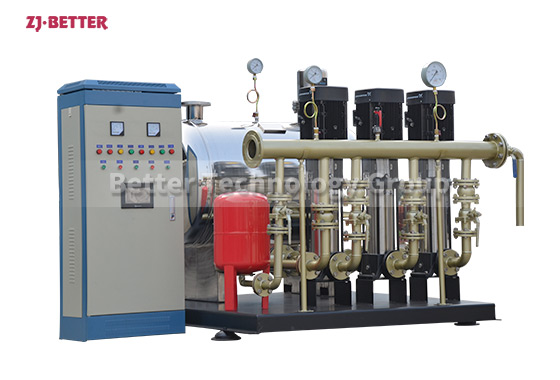

Better Technology Co., Ltd. was founded in 2002. We are locate in HangBu development zone, Quzhou, Zhejiang, with convenient transportation access, covering an area of 20000 square meters,for 15000 square meters workshop. It combines the functions of professional design, development, manufacture and sale of general fluid equipment of high-tech enterprise. Better Technology has own motor factory and control panel factory, can make customized product.

Better Pump has established many sales distributions and agencies in the major provinces in China. Through attending a variety of large scale exhibition, we have developed a broader market.

We are looking forward to forming successful business relationships with new clients around the world in the near future.