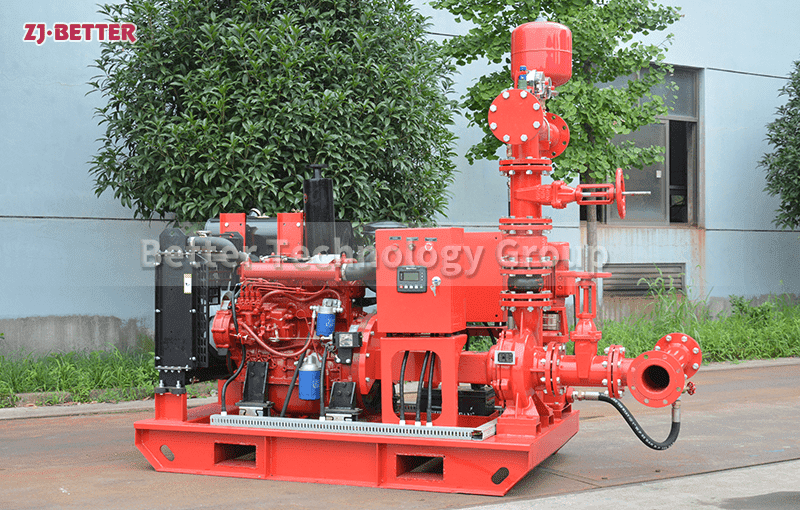

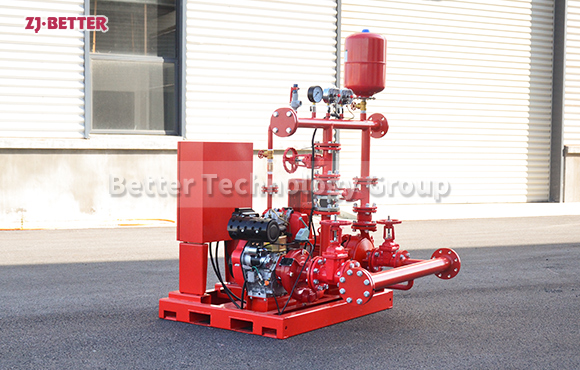

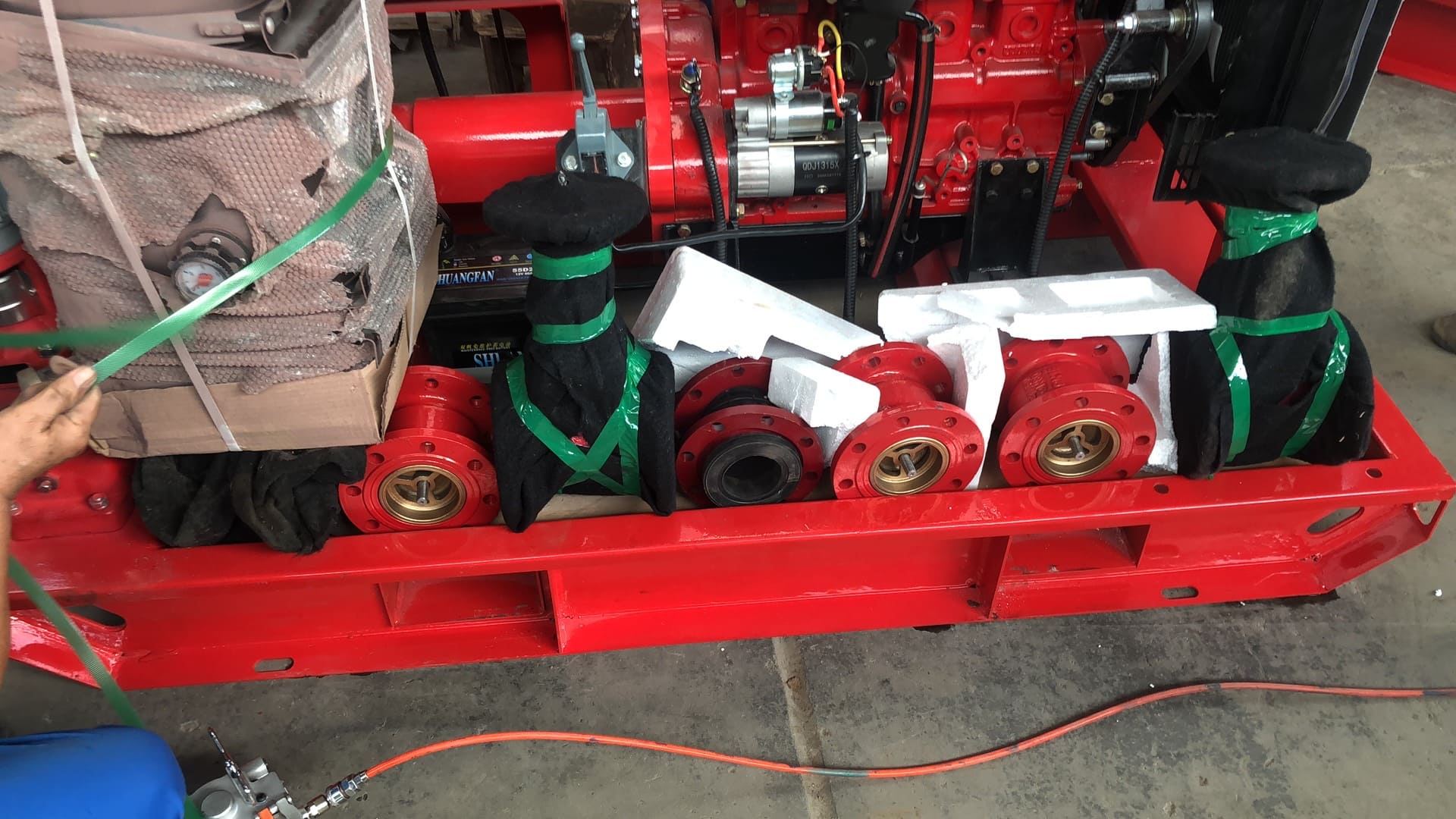

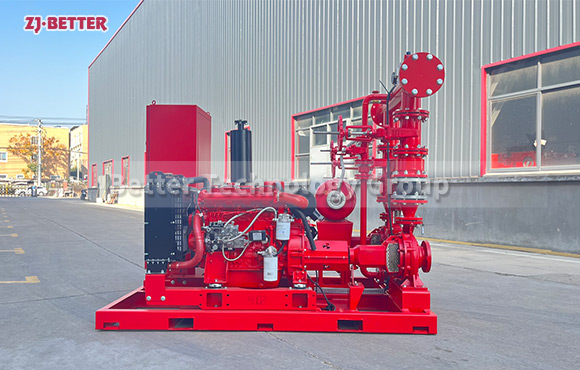

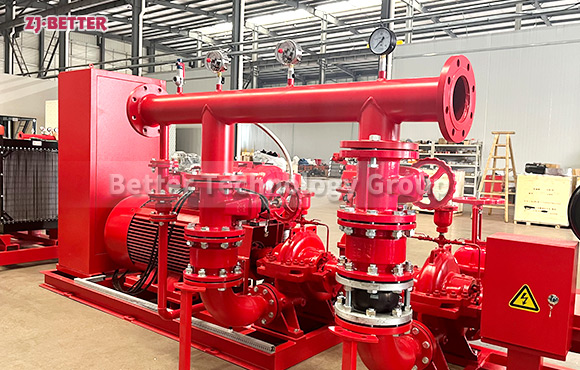

Popular emergency complete fire pump sets manufactured at the Better factory

The diesel engine fire pump has automatic, manual and fault self-checking functions. It can monitor the working state of the whole process, restore the function of failure start, automatic pre-lubrication and automatic restart of preheating, so that the equipment start-up is safer and more reliable. It has the functions of central control room remote control, remote control and field bus connection. The battery is fully automatic floating charge (constant current, constant voltage, trickle charge) mode to ensure that the battery is in a standby state at any time. Diesel engine fire pump is easy to use, equipped with remote instrument and instrument, which can be connected to the control center as needed, easy to install and use, and easy to maintain.

The engine cooling system of the diesel engine fire pump adopts double closed-loop heat exchangers. The system has the advantages of high cooling efficiency and little influence on the ambient temperature of the pump room. The cooling water flow direction is controlled by a ball valve from the pump outlet pipe to the heat exchanger, so that the cooling water temperature of the body is between 85 and 95 °C. If the water temperature is too high, the opening of the ball valve can be increased, the heat dissipation capacity of the heat exchanger can be increased, and the water temperature of the engine cooling water can be reduced. On the contrary, the opening of the ball valve can be closed to increase the water temperature of the engine cooling water.