Portable Diesel Fire Pump Parts

The main heat dissipation methods of diesel engine fire pumps can be divided into two types: wind heat dissipation and water heat dissipation. According to the two heat dissipation principles, the water heat dissipation system dissipates heat evenly and has a good heat dissipation effect. The relative price is also relatively low, so most diesel fire pumps mainly use water for heat dissipation. Wind cooling is divided into two types: natural wind and forced wind. Natural wind uses the airflow coming in from the machine in motion to directly cool the cylinder head, cylinder block and other parts; The airflow at the place increases the cooling rate and area. The principle of water heat dissipation is to use water or antifreeze as the cooling medium to take away the heat of the high-temperature parts of the diesel engine fire pump engine to ensure the normal working temperature of the engine.

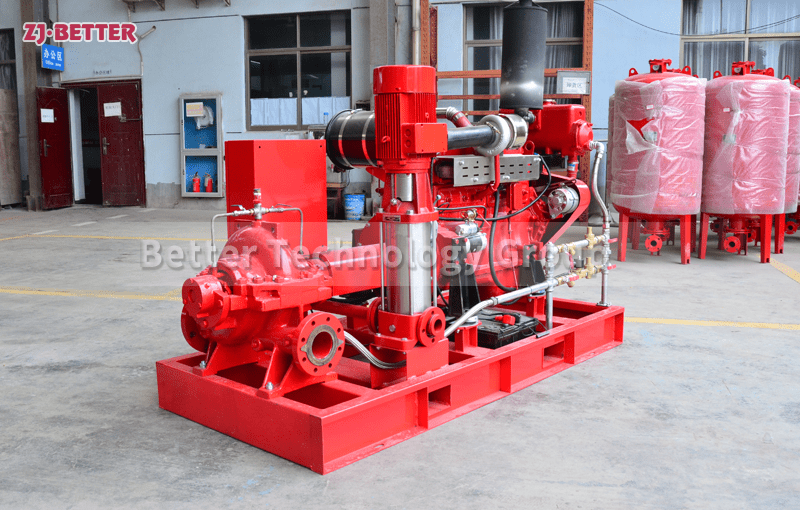

The diesel engine fire pump can adjust the pump head by increasing or decreasing the number of impeller stages according to the actual needs, so as to ensure that the working point falls within the high-efficiency area of ??the pump. Compared with ordinary diesel fire pumps, diesel fire pumps have higher pump efficiency, and the efficiency of diesel fire pumps is generally higher than that of multi-stage diesel fire pumps of the same flow level and domestic JC deep well pumps. Because the diesel engine fire pump can easily change the lift, the efficiency of the device can also be greatly improved. Diesel engine fire pumps can work in different working media and media with different temperatures by changing the material or coating with a special protective layer. The diesel engine fire pump occupies less floor space, and the diesel engine fire pump has less vibration and noise.