Protecting Your Assets: The Role of XBC-XA Diesel Fire Pumps in Fire Prevention

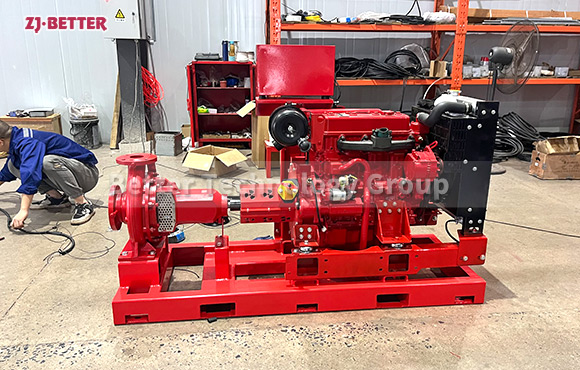

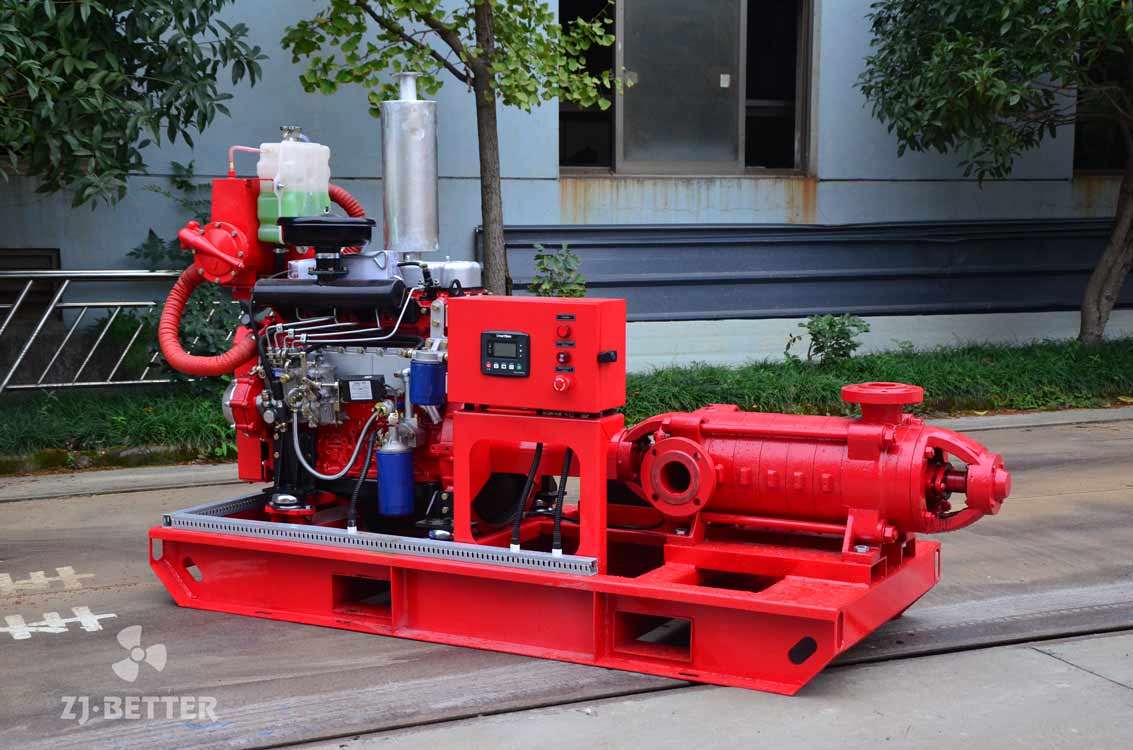

Experience efficient fluid transfer with the XBC-XA Diesel End Suction Pump. With its unique end suction design and powerful diesel engine, this pump offers reliable performance and exceptional pumping capacity. It is suitable for a wide range of applications, from industrial fluid transfer to fire protection systems. The XBC-XA Diesel End Suction Pump features automatic operation, advanced control systems, and automatic fault detection for added safety and convenience. Choose this versatile pump for reliable and efficient fluid transfer in various industries.

The XBC-XA Diesel End Suction Pump delivers exceptional pumping capacity and performance. Its powerful diesel engine provides the necessary power to move large volumes of fluids quickly and efficiently. Whether you’re transferring fluids in industrial settings or require fluid support for fire protection systems, the XBC-XA Diesel End Suction Pump is up to the task.

Designed for reliability, the XBC-XA Diesel End Suction Pump features a robust construction and advanced control system. It offers automatic operation and monitoring, ensuring optimal performance and efficiency. The pump’s automatic fault detection and alarm functions provide added safety and peace of mind, while its automatic protection mechanisms protect the pump during extended operation.

Versatility is a key feature of the XBC-XA Diesel End Suction Pump. It is suitable for various industries, including manufacturing, agriculture, construction, and more. Whether you need to transfer fluids for irrigation, supply water to remote locations, or support fire protection systems, the XBC-XA Diesel End Suction Pump is a reliable and efficient choice.