Reliable Fire Protection with XBC-S 100LPS, 100M Fire Pump: Safeguarding Your Safety

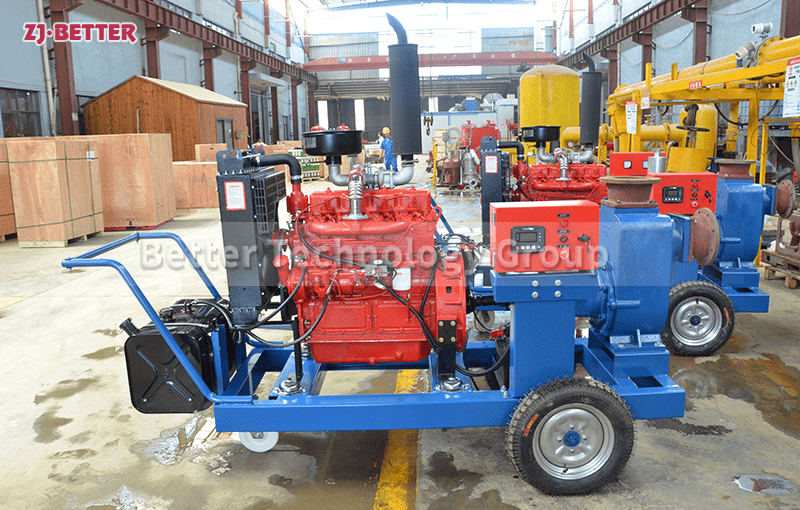

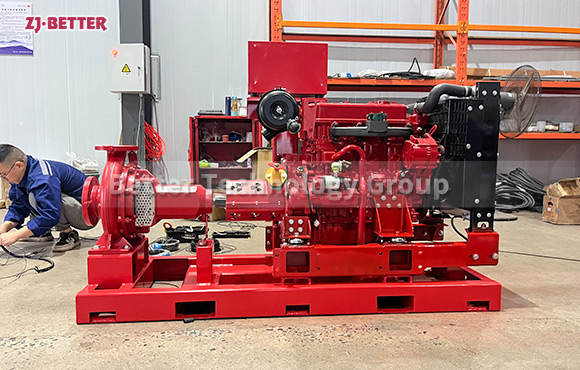

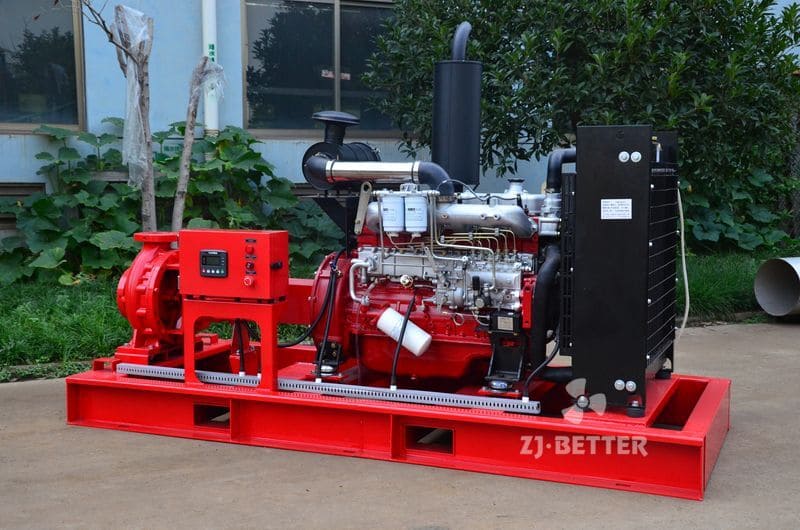

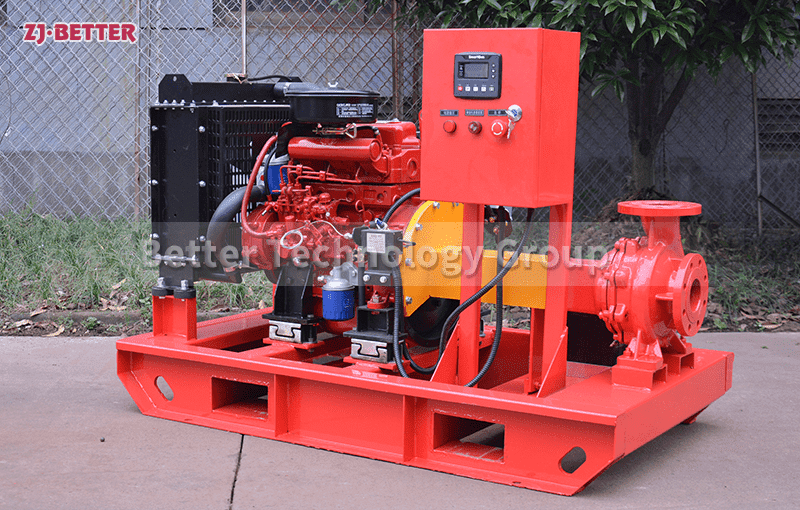

The XBC-S 100LPS, 100M fire pump boasts a flow rate of 100 liters per second and a head of 100 meters. This means it can swiftly deliver a large volume of water to the fire protection system, enabling quick response to fires and emergency situations. Whether in commercial buildings, industrial plants, or municipal projects, this fire pump provides reliable and efficient firefighting capabilities.

Manufactured using advanced technology and dependable materials, the fire pump ensures durability and long-term reliability. Equipped with an automatic control system, it intelligently monitors and adjusts water pressure and flow, ensuring a steady water supply.

The XBC-S 100LPS, 100M fire pump undergoes rigorous quality control and testing, complying with international fire standards and receiving certifications and approvals. Designed to withstand harsh environmental conditions, it exhibits excellent corrosion resistance and features a dustproof and waterproof design.

Whether for the installation of new fire protection systems or the upgrade of existing ones, the XBC-S 100LPS, 100M fire pump is a reliable choice. It provides efficient fire water supply, ensuring prompt and effective firefighting operations in the event of a fire.