Remote Sewage Transport Made Easy with Our Pump Truck

Flow:25-10000 GPM

Head:25 Bar

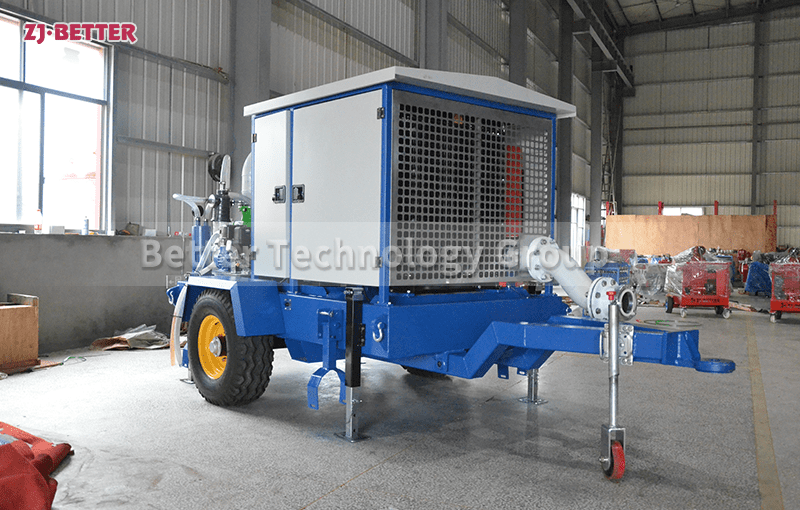

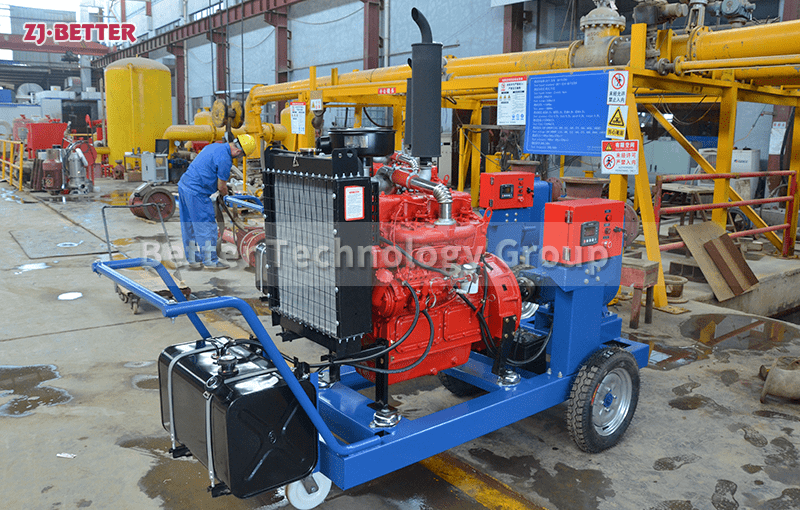

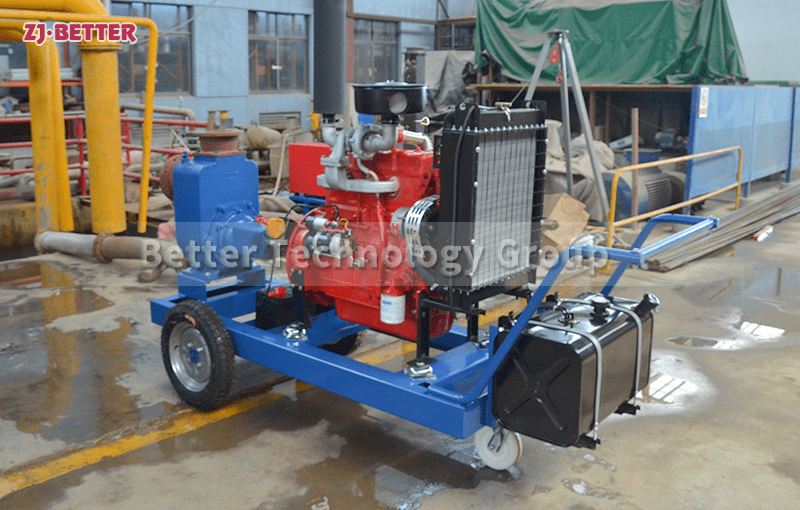

The mobile pump truck is a versatile and efficient solution designed for remote sewage and fluid transportation. It offers pump type options, including multi-stage, end-suction, or center-open pumps, and is powered by a reliable diesel engine. This trailer-style unit is highly mobile, with choices of two or four wheels and an enclosed or semi-open design. It features manual jacks for height adjustment, a traction device for balance, and meets safety standards with warning lights.

This mobile pump truck is designed for the remote transportation of sewage and other fluids. It offers several key features and functions:

1.Pump Type Selection: The mobile pump truck can be equipped with multi-stage pumps, end-suction pumps, or center-open pumps to accommodate various types of conveying tasks.

2.Power Source: Typically, the truck is powered by a diesel engine, providing ample power to handle different environmental and working conditions. Diesel engines are known for their durability and reliability.

3.Trailer-Style Structure: It adopts a trailer-style structure, making it easy to tow to different job sites. Users can choose between two-wheel or four-wheel versions to suit different road and terrain conditions.

4.Exterior Options: The mobile pump truck offers both enclosed and semi-open exterior options, catering to users’ preferences and specific working environments.

5.Jack Support: It comes with a system of four manual jacks, allowing users to adjust the vehicle’s height as needed to ensure stability on uneven terrain.

6.Traction Device: The wheeled chassis includes a traction device, enabling users to adjust the vehicle’s balance as necessary for stable operation during tasks.

7.Safety Equipment: To ensure transport safety, the mobile pump truck is equipped with warning lights, side lights, fog lights, and other safety devices, complying with national and Australian transportation safety standards.

8.Fueling System: It features a convenient fueling system with a lockable fuel inlet to ensure safe fuel storage and usage.

In summary, this mobile pump truck is a versatile remote conveying device suitable for outdoor operations. It boasts features such as towing capability, height adjustment, safety measures, and convenient fueling, and can be customized and configured to meet various requirements. This equipment has broad potential applications in handling sewage and other fluid conveying tasks.