Selection of fire pump

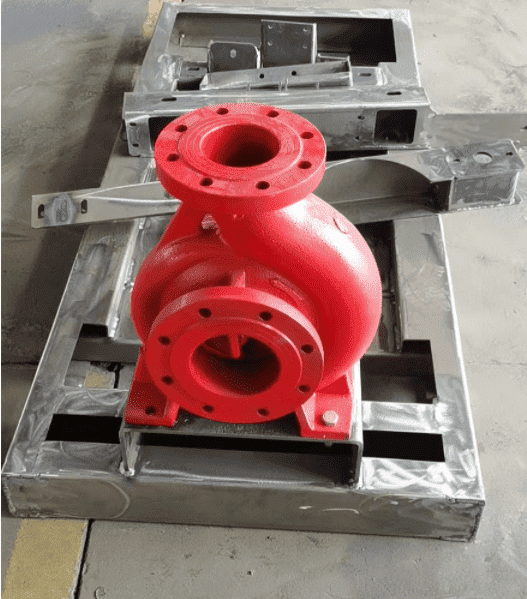

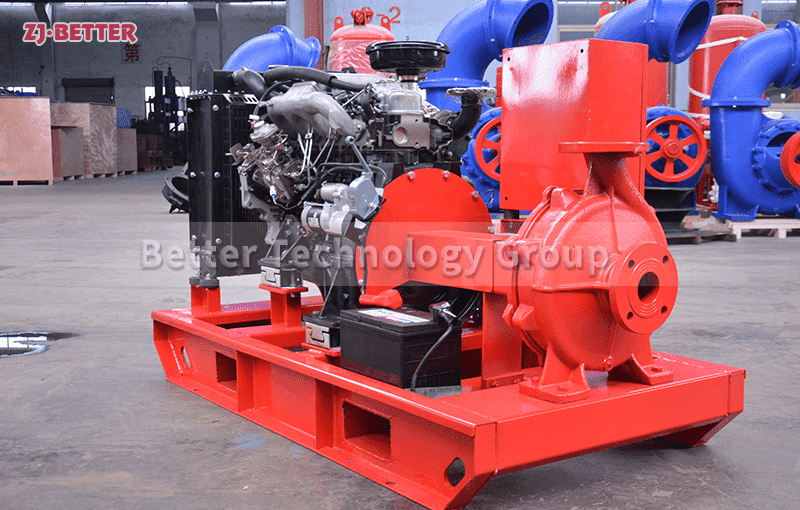

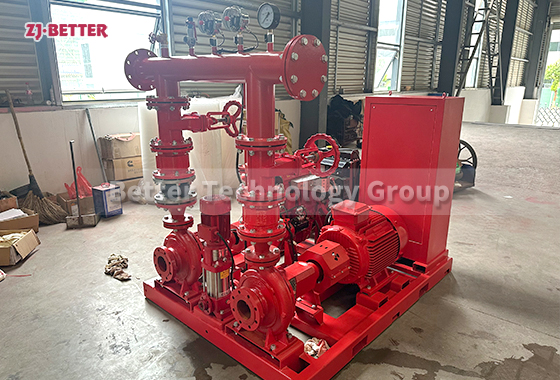

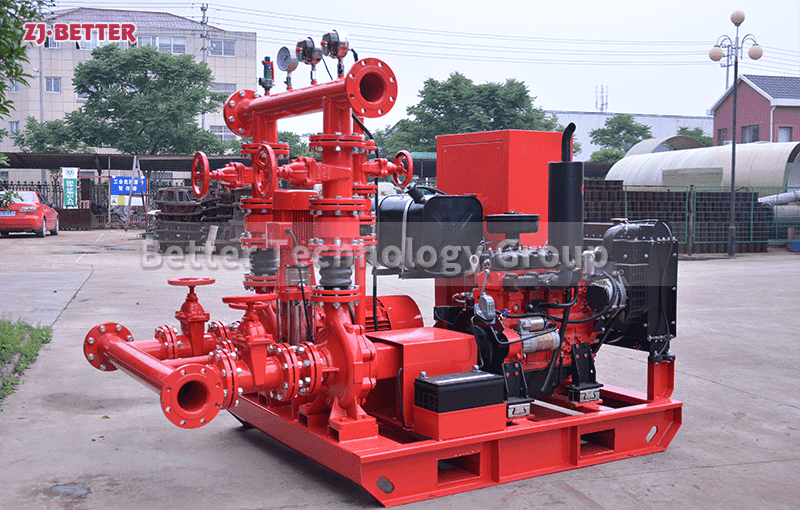

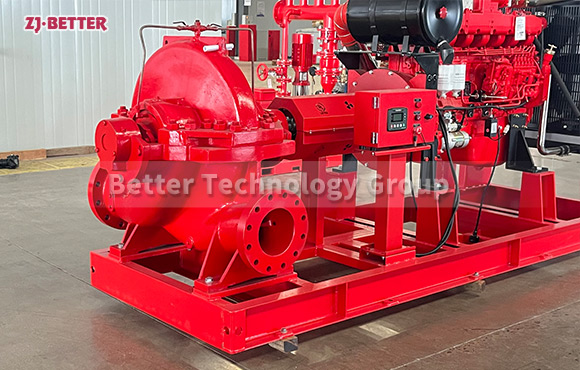

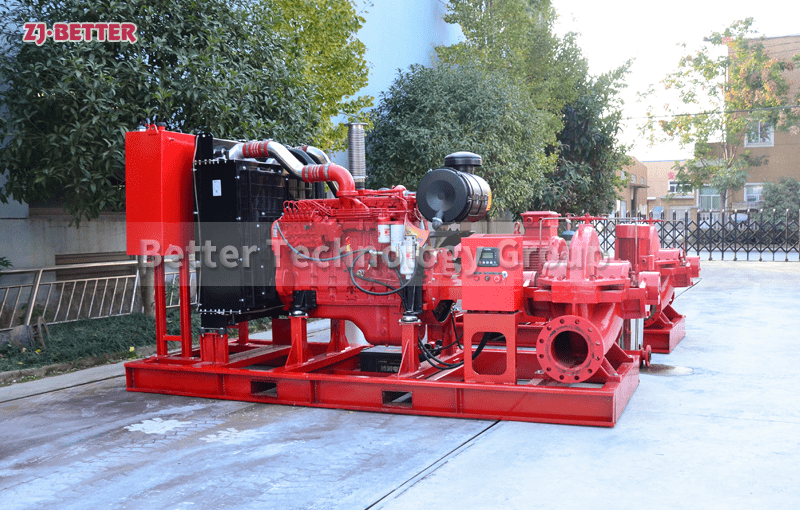

The basis for the selection of fire pumps should be based on the process flow, water supply and drainage requirements, and be considered from five aspects, namely, liquid delivery volume, device lift, liquid properties, pipeline layout, and operating conditions. Fire pumps are mainly divided into vertical and horizontal types. The flow rate of the conveying liquid is one of the important performance data for pump selection. It is directly related to the production capacity of the entire device. The working conditions of the fire pump: flow rate: 2~1400m3/h, Head: 5~130m, maximum working pressure of the system: ≤1.6MPa, working temperature: -15℃~+80℃.

The basis for the selection of fire pumps should be based on the process flow, water supply and drainage requirements, and be considered from five aspects, namely, liquid delivery volume, device lift, liquid properties, pipeline layout, and operating conditions. Fire pumps are mainly divided into vertical and horizontal types. The flow rate of the conveying liquid is one of the important performance data for pump selection. It is directly related to the production capacity of the entire device. The working conditions of the fire pump: flow rate: 2~1400m3/h, Head: 5~130m, maximum working pressure of the system: ≤1.6MPa, working temperature: -15℃~+80℃.