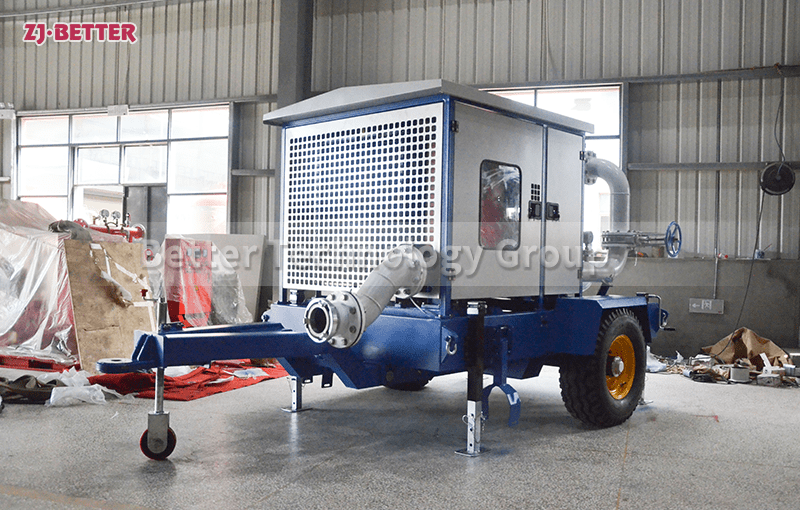

Single-bar diesel engine self-suction pump mobile self-suction pump truck

There are many types of single-cylinder diesel engine self-suction and anti-pump fire pumps, of which the water discharged by the impeller to the gas separation room is returned to the water pores at the outer edge of the impeller’s leaf wheel. Under the influence of pressure differences and gravity, the water flowing back to the left water hole is shot into the impeller channel and broken by the impeller. After the air is inhaled from the pipeline, it is dumped into the snail shell. The gear pump, resistance pump, and fire pump flow in the direction of rotation. Then, combined with the water flowing from the right back to the water, it flows along the snail shell. Because the diesel pump continues to impact the leaf grid in the snail shell and is constantly being broken by the impeller, it is strongly mixed with the air to generate a mixture of gas and water. The mixture is stripped by the tongue at the exit of the snail shell and enters the separation room along the short tube. The air in the separation room is separated and discharged from the exit pipe, and the water still flows back to the outer edge of the impeller through the left and right pores, and is mixed with the air inhaled from the pipeline. This repeated cycle is gradually exhausted into the air in the pipeline, so that the water enters the pump and completes the self-suction process.

There are many types of single–cylinder diesel engine self–suction and anti–pump fire pumps, of which the water discharged by the impeller to the gas separation room is returned to the water pores at the outer edge of the impeller‘s leaf wheel. Under the influence of pressure differences and gravity, the water flowing back to the left water hole is shot into the impeller channel and broken by the impeller. After the air is inhaled from the pipeline, it is dumped into the snail shell. The gear pump, resistance pump, and fire pump flow in the direction of rotation. Then, combined with the water flowing from the right back to the water, it flows along the snail shell. Because the diesel pump continues to impact the leaf grid in the snail shell and is constantly being broken by the impeller, it is strongly mixed with the air to generate a mixture of gas and water. The mixture is stripped by the tongue at the exit of the snail shell and enters the separation room along the short tube. The air in the separation room is separated and discharged from the exit pipe, and the water still flows back to the outer edge of the impeller through the left and right pores, and is mixed with the air inhaled from the pipeline. This repeated cycle is gradually exhausted into the air in the pipeline, so that the water enters the pump and completes the self–suction process.