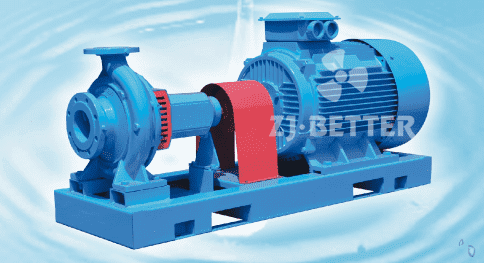

Single stage centrifugal pump

Single stage centrifugal pump includes pump body, pump cover, motor with output shaft, pump shaft, bearing seat, impeller, mechanical seal and mechanical seal gland installed in the pump body, which are connected with the motor through extended elastic coupling. The rotation direction of the pump, viewed from the driving end, is clockwise. Wanfulong is characterized in that it also includes a clip on coupling arranged between the motor output shaft and the pump shaft, and a guide bearing installed on the bearing seat to assist in supporting the pump shaft; The wafer type coupling is rigidly connected with the motor output shaft and the pump shaft respectively, and a space distance is left between the motor output shaft and the pump shaft to facilitate the assembly and disassembly of the mechanical seal and the mechanical seal gland. When repairing or replacing the mechanical seal, it is not necessary to disassemble the motor and pump cover.

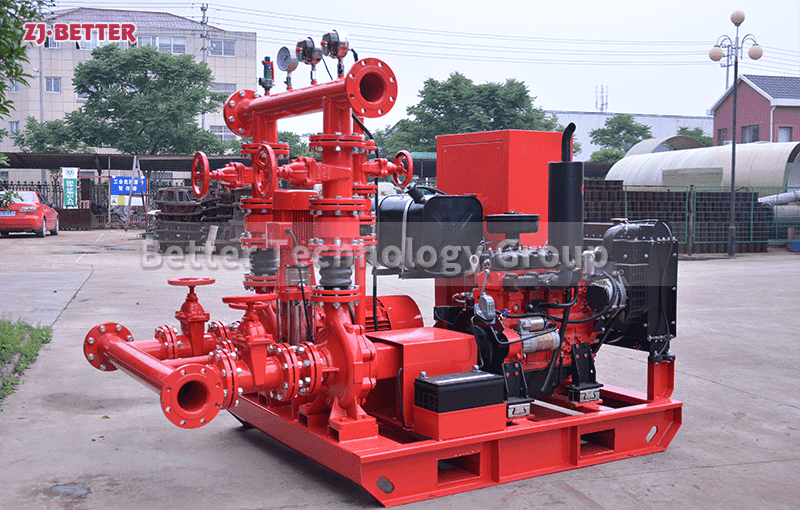

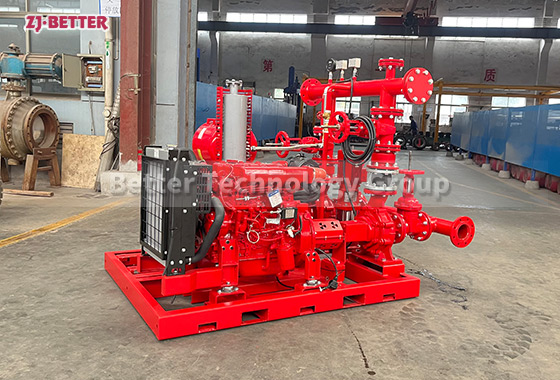

The main products of the company include submersible fire pumps, urban emergency drainage pumps, diesel fire pump sets, gas top pressure fire water supply equipment, oil-water separation equipment in catering industry, tank pump integrated fire pressurization and pressure stabilization water supply equipment, B-series submersible sewage pumps, AST series special sewage pumps for building civil engineering, WQ, QW series submersible sewage pumps, ISG, IRG, IHG, isgd series vertical pipeline pumps, ISW, iswd series horizontal centrifugal pumps, DL type vertical multistage pumps GDL portable pipeline multi-stage pump, LG, LG-B portable high-rise building water supply multi-stage pump, etc. The main products of the company are in line with the high-tech fields supported by the state.