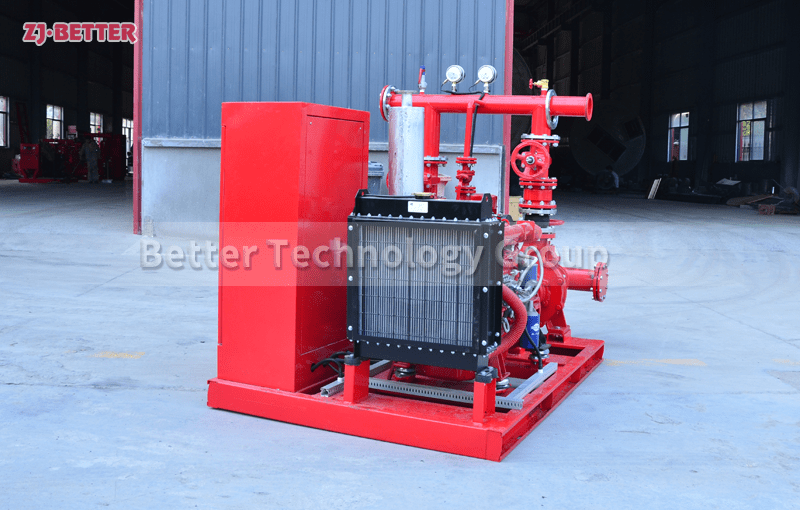

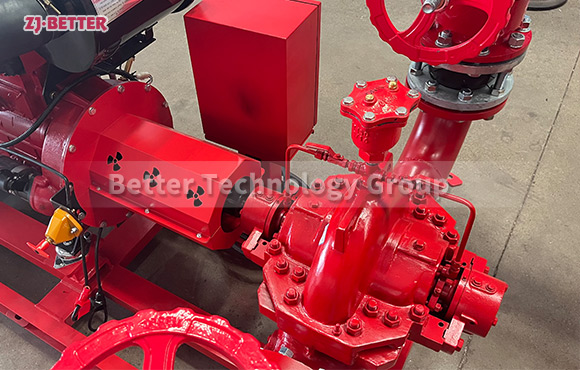

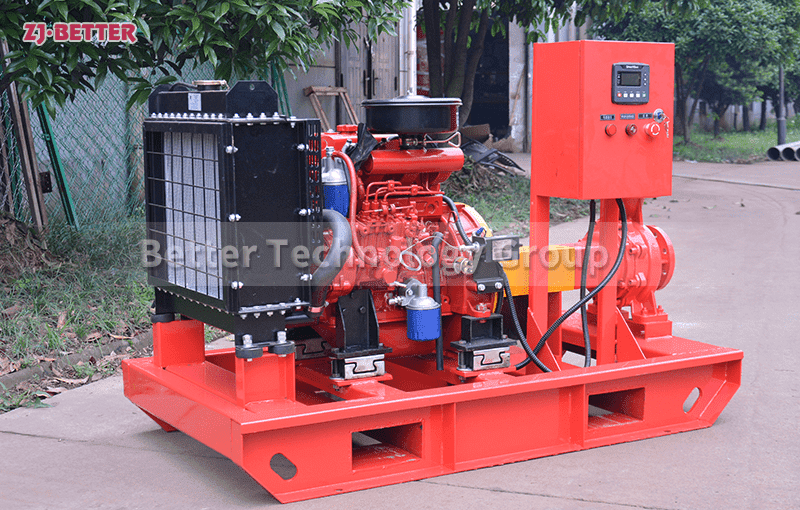

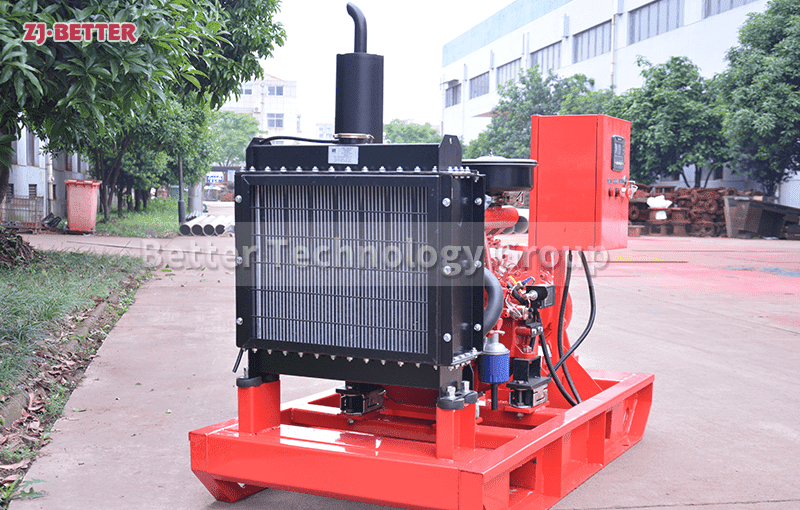

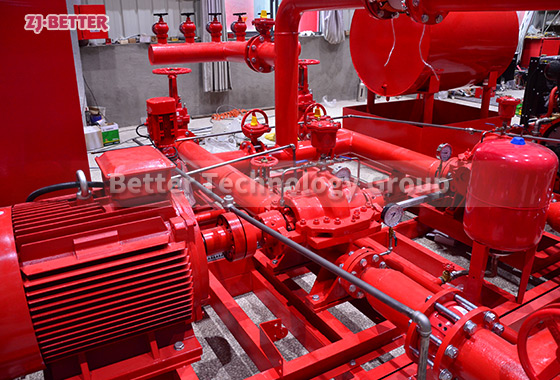

SKID MOUNTED FIRE PUMP SET

Spectrum range: fire pump can use a single-stage end suction pump,a combination of multistage single-suction pumps, single-stage double-suction pumps and other kinds of pumps, pump or more kinds of parallel flow, wide pressure range.

Automatically. when the engine fire pump receives a valid signal fire, remote control start signal when the unit will start automatically; when the fire pump motor supply failure or lack of signal phase, the unit will automatically standby. Diesel fire pump start 10s, if not start running, stop 10s, and then restart. The unit will automaticaly repeat three times.

Alarm System: repeatedly failed to start alarm, low diesel engine oil pressure alarm, ultra-high temperature alarm diesel engine, diesel engine speed alarm, low battery alarm, charging failure alarm, an alarm indicating a lack of fuel.

kinds of ways to start signal fire started, manually start or remote start.

Spectrum range: fire pump can use a single-stage end suction pump,a combination of multistage single-suction pumps, single-stage double-suction pumps and other kinds of pumps, pump or more kinds of parallel flow, wide pressure range.

Automatically. when the engine fire pump receives a valid signal fire, remote control start signal when the unit will start automatically; when the fire pump motor supply failure or lack of signal phase, the unit will automatically standby. Diesel fire pump start 10s, if not start running, stop 10s, and then restart. The unit will automaticaly repeat three times.

Alarm System: repeatedly failed to start alarm, low diesel engine oil pressure alarm, ultra-high temperature alarm diesel engine, diesel engine speed alarm, low battery alarm, charging failure alarm, an alarm indicating a lack of fuel.

kinds of ways to start signal fire started, manually start or remote start.