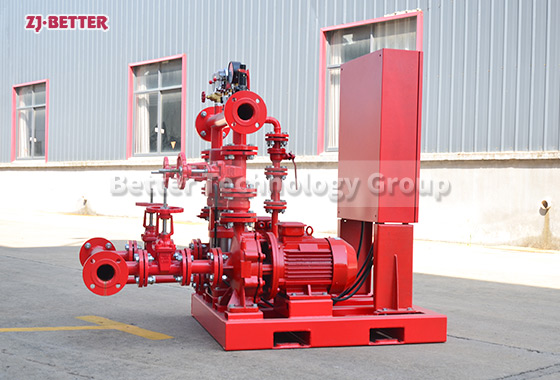

Small DJ (diesel pump and jockey pump) fire pump set for emergency use

Flow: 30-9000GPM

Head:3-20Bar

Caliber: 25-800mm

Power: Diesel pump / Electric pump: 1.5-710 kw, Jockey pump: 0.55-160kw

Speed: 740-2900r/min

Material:SS304, Bronze

1. Diesel engine pump, can use single stage pump, horizontal split case pump, end suction pump, multistage pump, material can be cast iron, stainless steel, and bronze impeller , with fuel tank, water tankfan, control box

2. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump Jockey material casing: cast iron, shaft and impeller: SS304

3. Control panel: Auto Control of diesel engine pump and Jockey Pump with overload, over current protection

4. Accessories: check valve, gate valve, pressure vessel, generally 0.6mpa, 1.0mpa, 1.6mpa, Pressure Gauge, Pressure Sensor, Common Pipe for Suction and Discharge, Flexible Joints and Flanges, Common Base plant