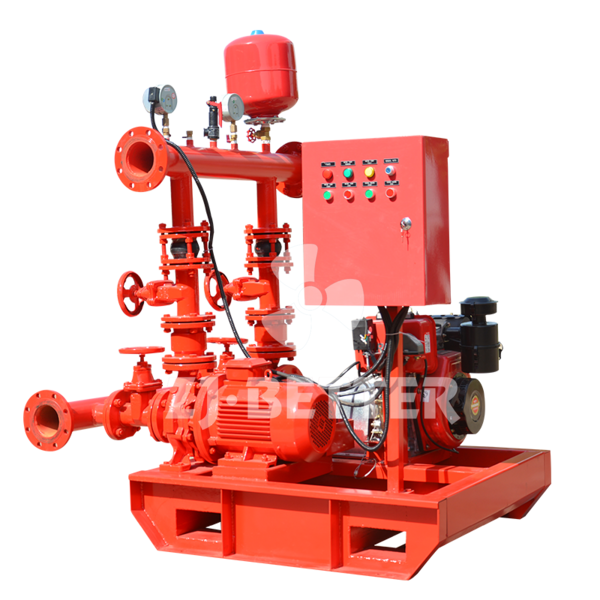

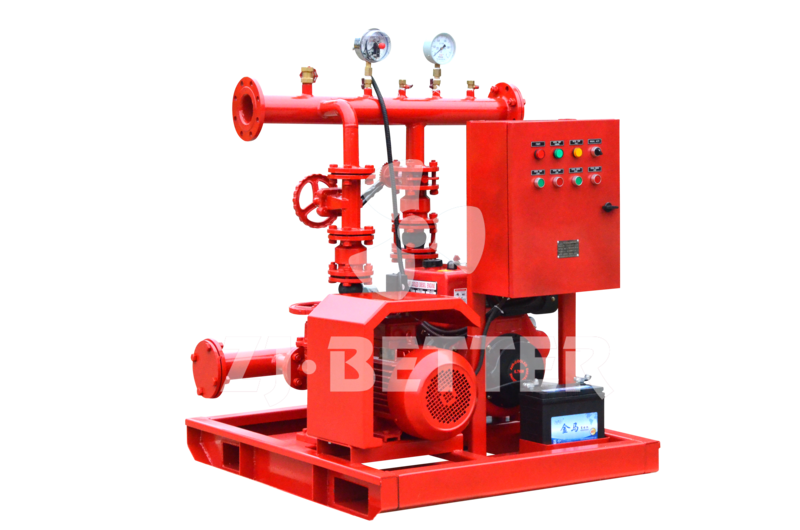

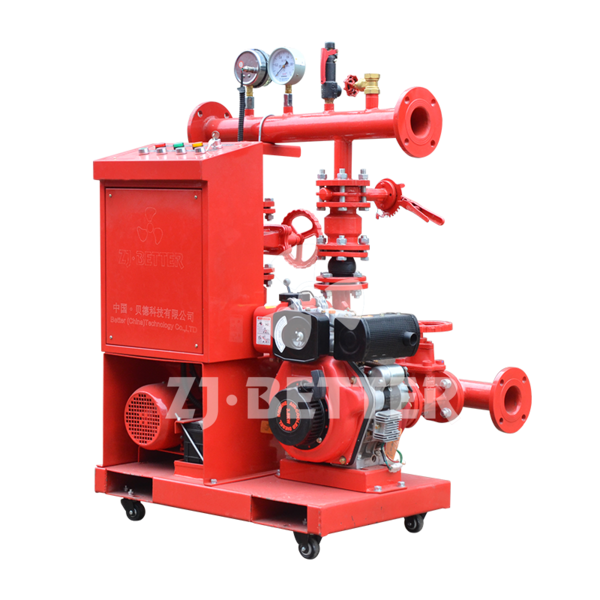

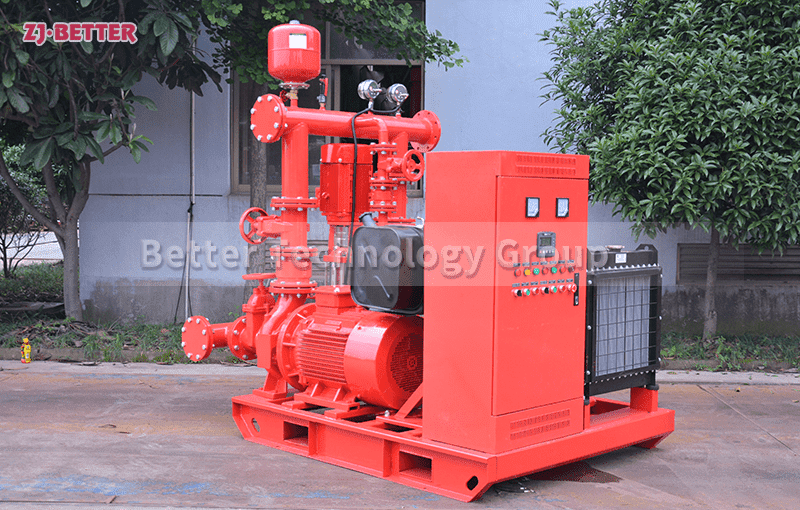

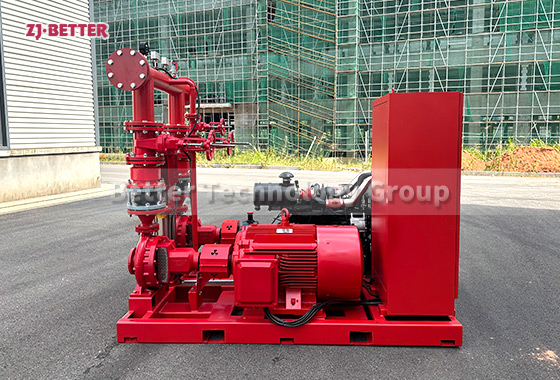

ED(EDJ/EJ/DJ/EEJ) small Fire Fighting package set water supply equipment (abbreviated as ED small FireFighting package set water supply equipment) refers to the flow less than 100 GPM and A highly integratedmechanical and electrical system consisting of electric centrifugal pump, multi-stage centrifugal pump (pressurizedpump group), Diesel Engine Centrifugal pump, pressure limiting protection device (safety valve), valve fittings,control system, pressure sensor system, water-free protection device, backflow preventer, soft joint. bypasspipelines, common base, filters, etc. It is a fire water supply equipment that continuously supplies water to thefire pipe network by preset pressure mode. All accessories of ED small fire fighting package set water supplyequipment are assembled according to the standard (NFPA20). Its configuration depends on the needs ofcustomers, or the number of pumps and the type of electric and diesel pump. ED small fire fighting package setwater supply equipment is usually equipped with two pumps, one main pump (electric centrifugal pump) andone standby pump (diesel centrifugal pump). The selection of motor and diesel engine depends on the reliabilitylevel of the system.