Small flow DJ fire pump set customized on request

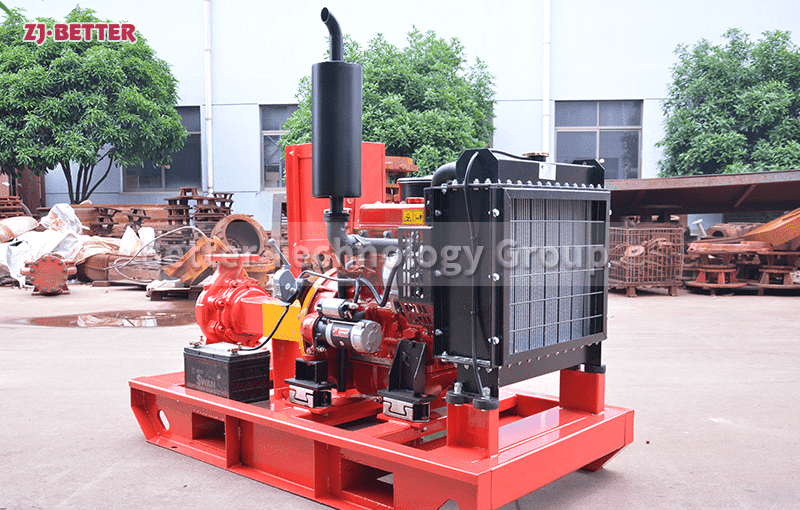

The DJ model is basically a combination of a diesel engine and a jockey pump. They consist mainly of end suction pumps driven by diesel engines and have no backup pumps. It is also combined with a jockey pump for maintenance to form a complete skid.

The complete DJ style skid is assembled with all discharge line fittings and connected to the skid mounted control panel.

Available DJ-type fire pump skid kits provide the following flows:

50, 120, 150, 250, 300, 350, 500, 750 and 1000 GPM.

Standard pump kits are available as complete skid-mounted units. Each skid unit includes a high quality horizontally split box or end suction pump combined with a heavy duty drive, electric motor or diesel engine. Accessories are also assembled in the same unit, and skids, such as gate valves, check valves, flexible joints, pressure switches and pressure gauges, are installed with the support head. All of these components are pre-piped, wired and fabricated on a universal compact slide and run as a fully automatic unit using the latest design control panel.

We offer combinations and models of innovative designs to meet client and project requirements. We also have the ability to provide custom designs and solutions for special hazardous applications.