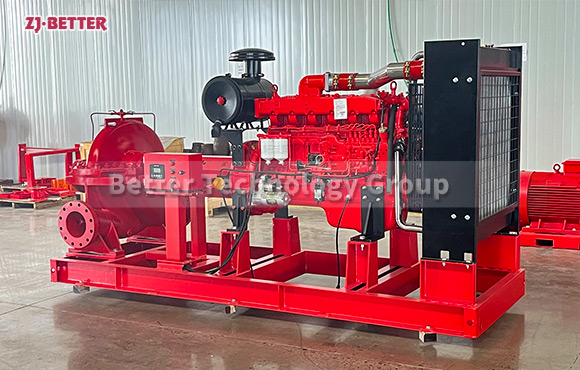

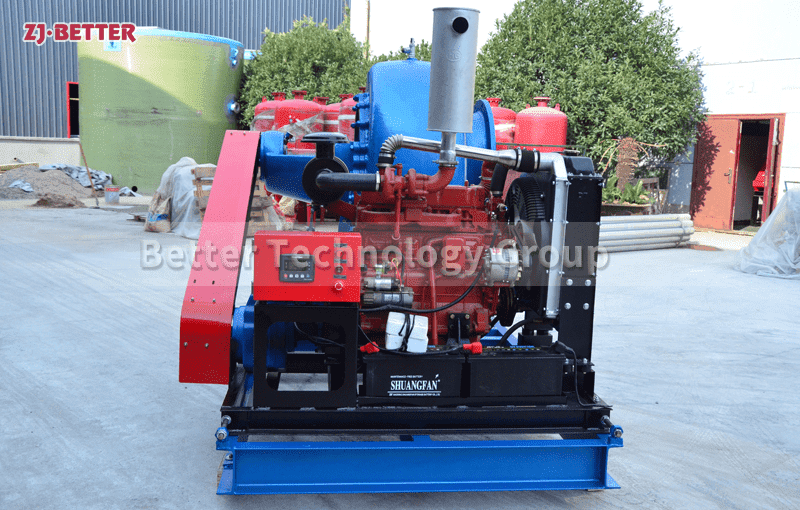

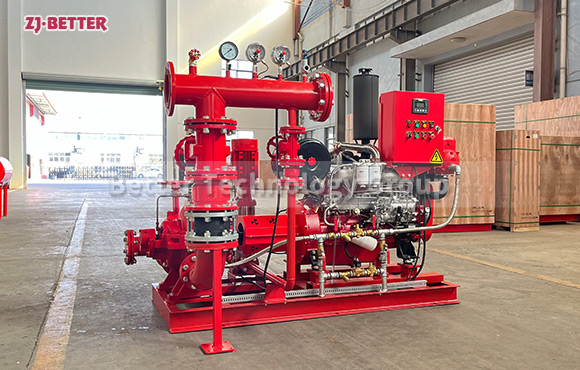

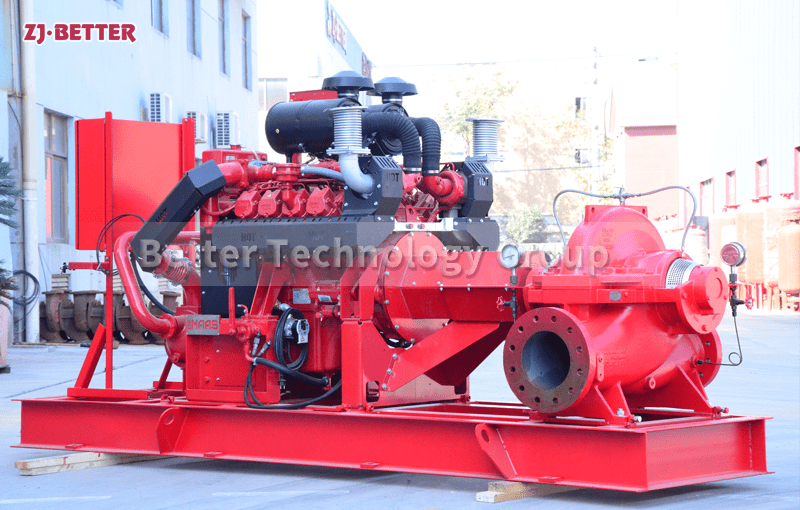

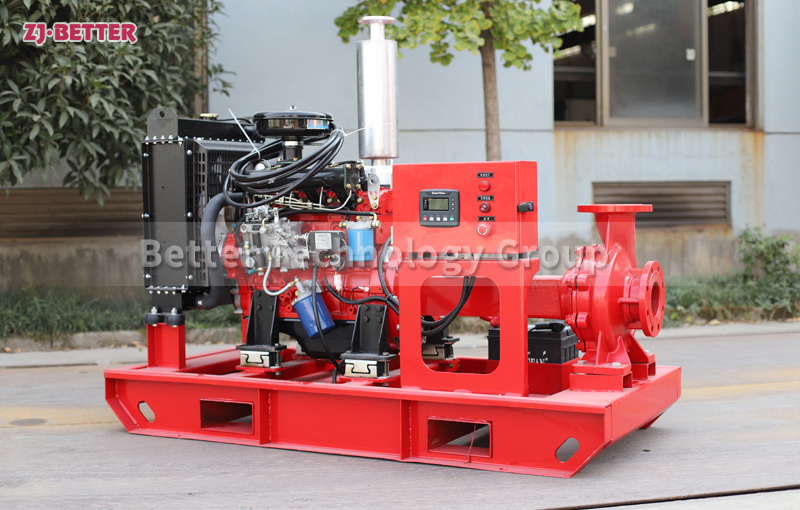

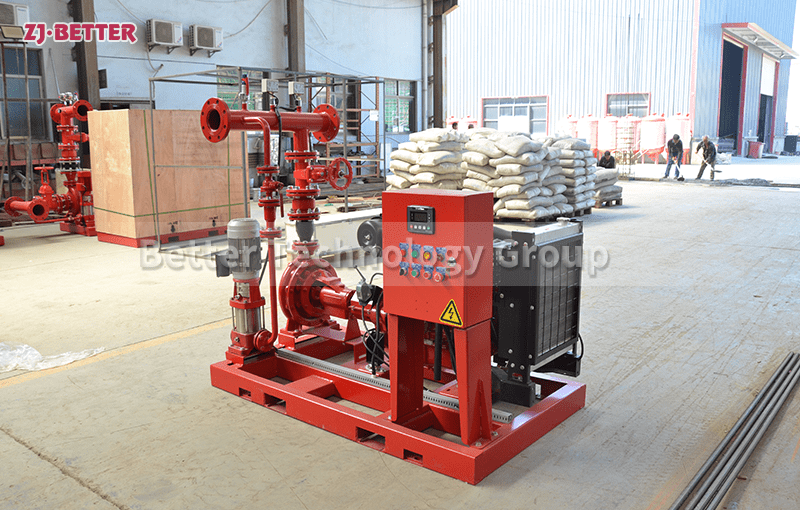

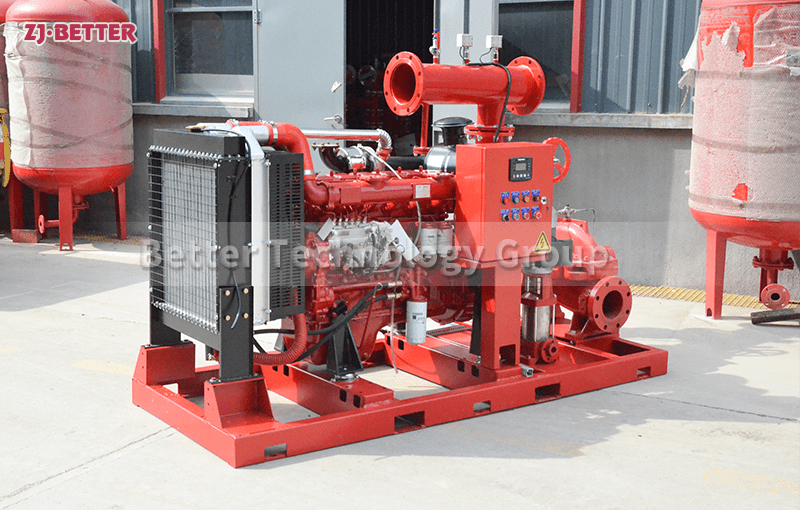

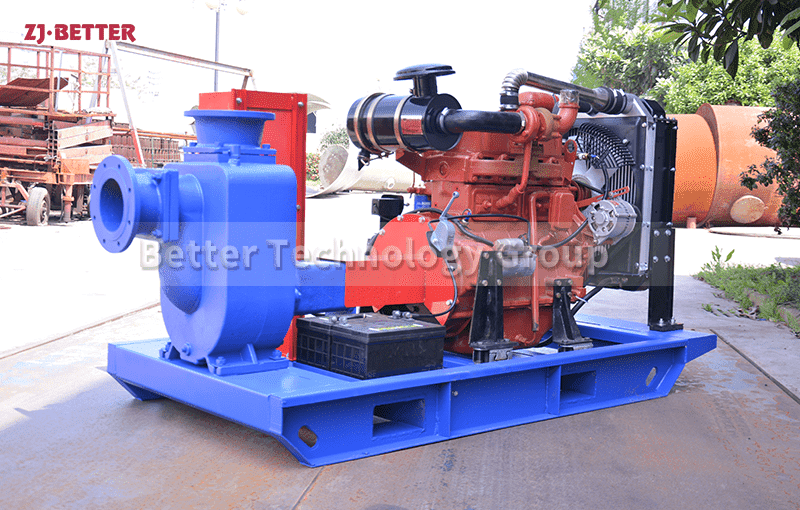

Split case diesel pump set 67kw

The flow rate of ordinary diesel pump is generally low, and sometimes it can not meet the requirements of customers. Nowadays, the diesel pump with large flow rate has been developed. It uses double suction ports, which is twice the flow rate of ordinary diesel pump. Moreover, the structure is more reasonable, the NPSH is small, and it is more durable,

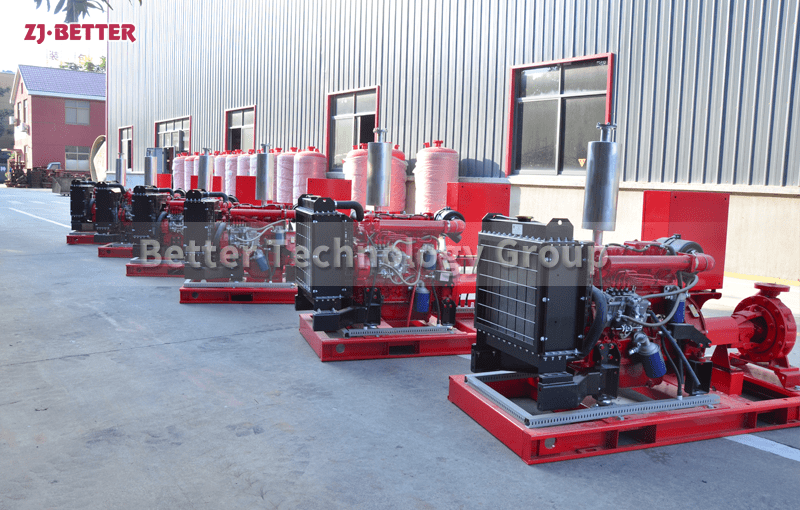

Zhejiang Better Pump Industry Co., Ltd.

The company’s main products are submersible fire pump, city emergency drainage pumps, diesel fire pumps, gas top pressure fire water supply equipment, catering oil-water separation equipment, tank fire booster pump integrated regulator water supply equipment, B series submersible sewage pump, AST Building Civil dedicated

sewage pump series, WQ, QW series submersible sewage pump, ISG, IRG, IHG, ISGD series vertical pipeline pump, ISW, ISWD series of horizontal centrifugal pumps, DL Vertical multi-stage pump, GDL type will be demolished multi-stage pipeline pump, LG, LG-B type will be demolished high-rise building water supply multi-stage pumps. The company’s main products are in line with high-tech fields supported by the state.