Split Case Fire Pump System Designed for Industrial and Municipal Projects

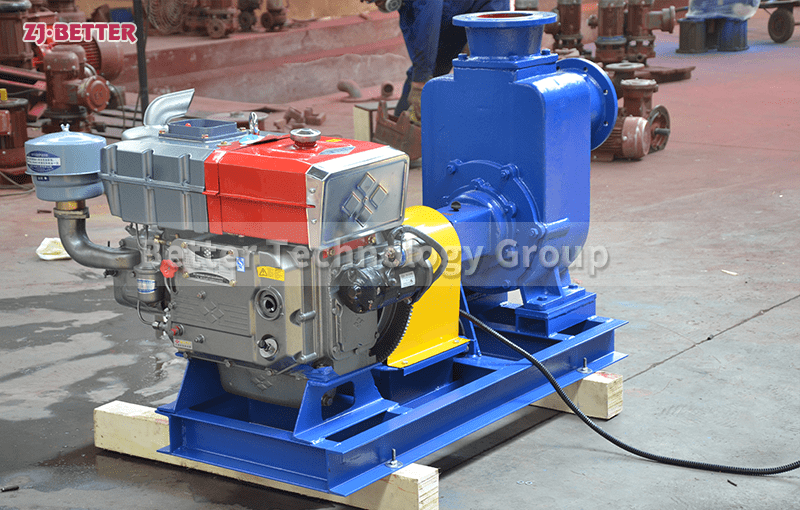

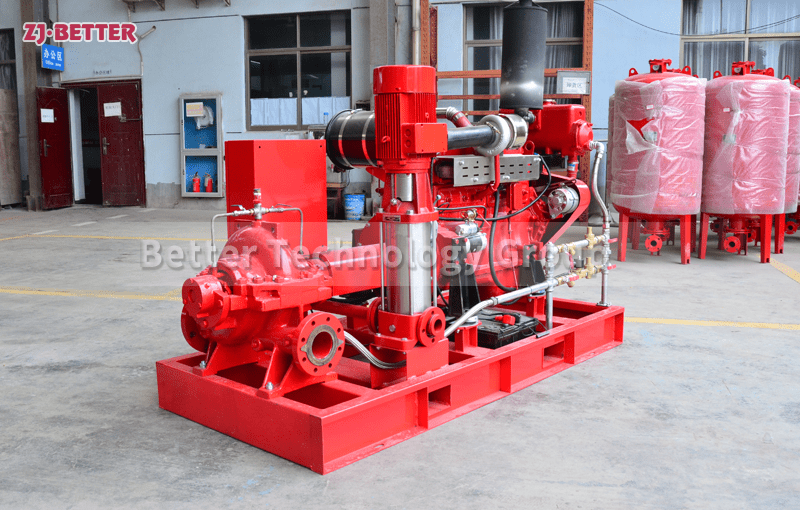

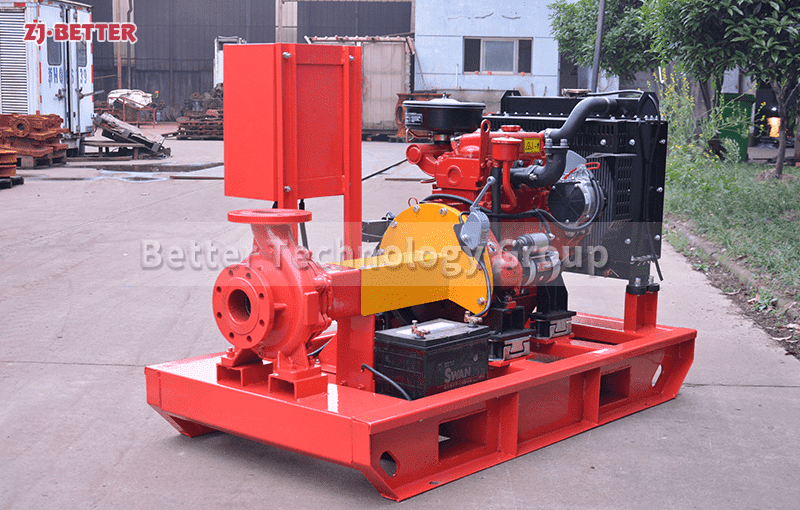

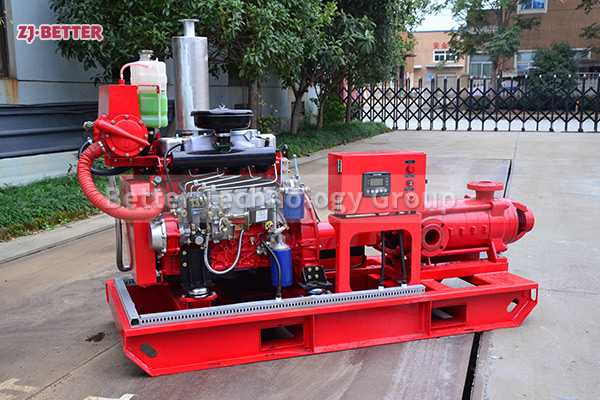

For large-scale industrial facilities, airports, water plants, and municipal projects, selecting a reliable and high-efficiency fire pump system is crucial. This split case fire pump system is engineered with a horizontal design and is available with both diesel engine and electric motor drive options. It features high flow rates, excellent head performance, and strong anti-cavitation capability.

The double-suction design minimizes axial thrust, ensuring smoother operation and longer service life—ideal for continuous-duty firefighting applications. With its modular construction, the system is easy to install and maintain on site, helping reduce project timelines and operational costs.

Whether deployed in petrochemical zones, power plants, or urban complexes, this split case fire pump system provides robust protection for your fire water supply infrastructure

Specializing in the development and manufacturing of high-performance fire pump systems, the company offers a comprehensive range of products, including electric pump units, diesel engine pump units, dual power supply systems, and pressure maintenance equipment. All products are strictly designed and tested in compliance with both domestic and international fire protection standards, ensuring dependable and efficient water supply in emergency scenarios.

Over the years, the systems have been widely applied in critical projects across petrochemical plants, power stations, rail transit systems, airports, and municipal infrastructure. Renowned for their stability and outstanding performance, the products have earned strong customer trust. Driven by continuous innovation and intelligent manufacturing, the company is committed to delivering professional fire protection solutions to users around the world.