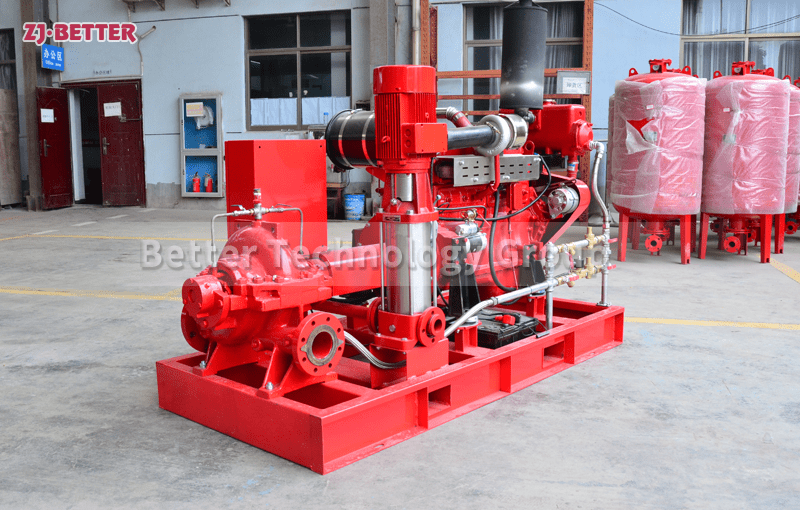

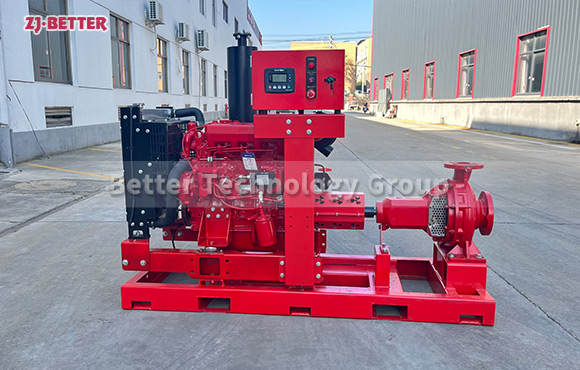

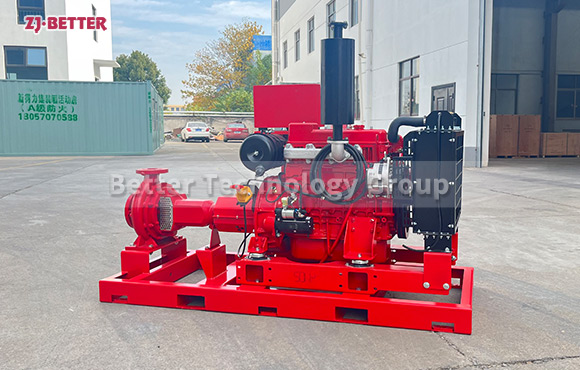

Stable performance of diesel engine fire pump

Diesel engine fire pumps can choose ductile iron and 304 stainless steel materials, which can meet various special use conditions and technical requirements of users, and diesel engine fire pumps can be matched with different brands of diesel engines to ensure stable performance and long service life of diesel engine fire pumps Long, high degree of automation.

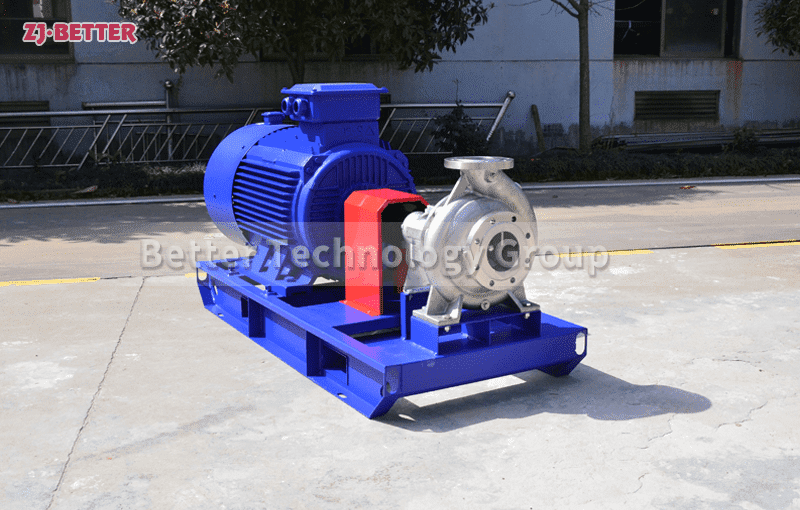

The application of fire pumps is not only in fire protection systems, but a variety of fire pumps are gradually showing their superior strength in industrial production and urban construction. This includes the implementation and expansion of high-end technologies for industrial and urban water supply and drainage, and high-rise building underpressure water delivery.

Of course, the long-distance water delivery that we are familiar with is indispensable. These aspects that we may ignore are inseparable from the application of fire pumps. Even the heating of bathrooms and the circulation of hot and cold water in boilers depend on the assistance of fire pumps of some practical type.

.jpg)