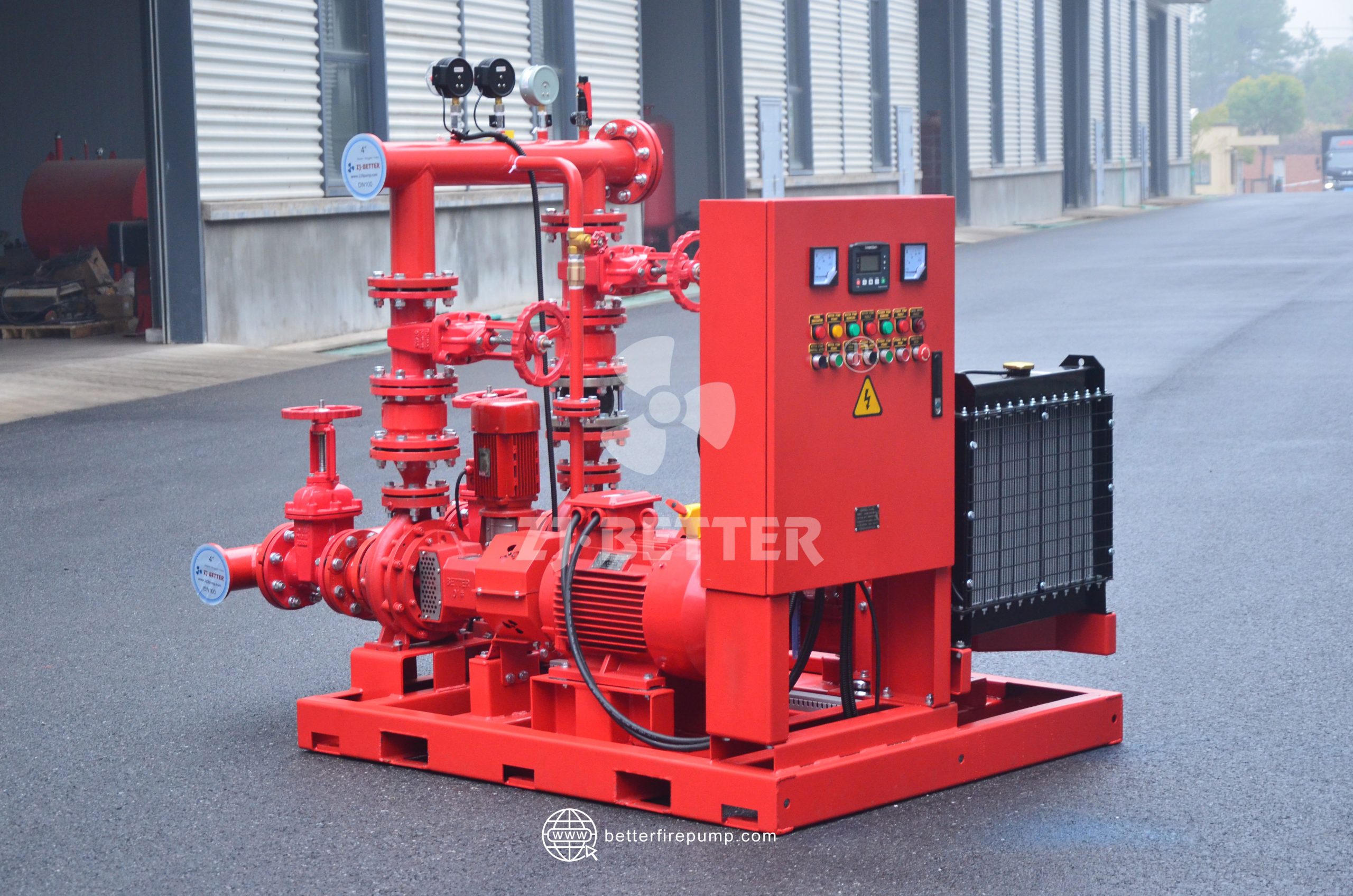

Stable performance of diesel engine fire pump set

Diesel engine fire pumps are suitable for use in high lift and high flow fire water supply environments or as backup fire water supply pumps. The reason is that the diesel engine has strong power and can be used with large flow fire deep well pumps, and the diesel engine fire pumps have the characteristics of self-starting when power is off. Emergency water supply available.

Due to its stable performance and high frequency of use, diesel engine fire pumps can be matched with various domestic and foreign brands of diesel engines according to user needs, and can be selected according to the required head, flow, power and fire pump material requirements to ensure stable use by customers. Diesel engine fire pumps operate automatically It is simple, adopts good hydraulic design and structural design, and has high operating efficiency. It is very suitable for applications in warehouses, docks, power plants, textiles and other enterprises.