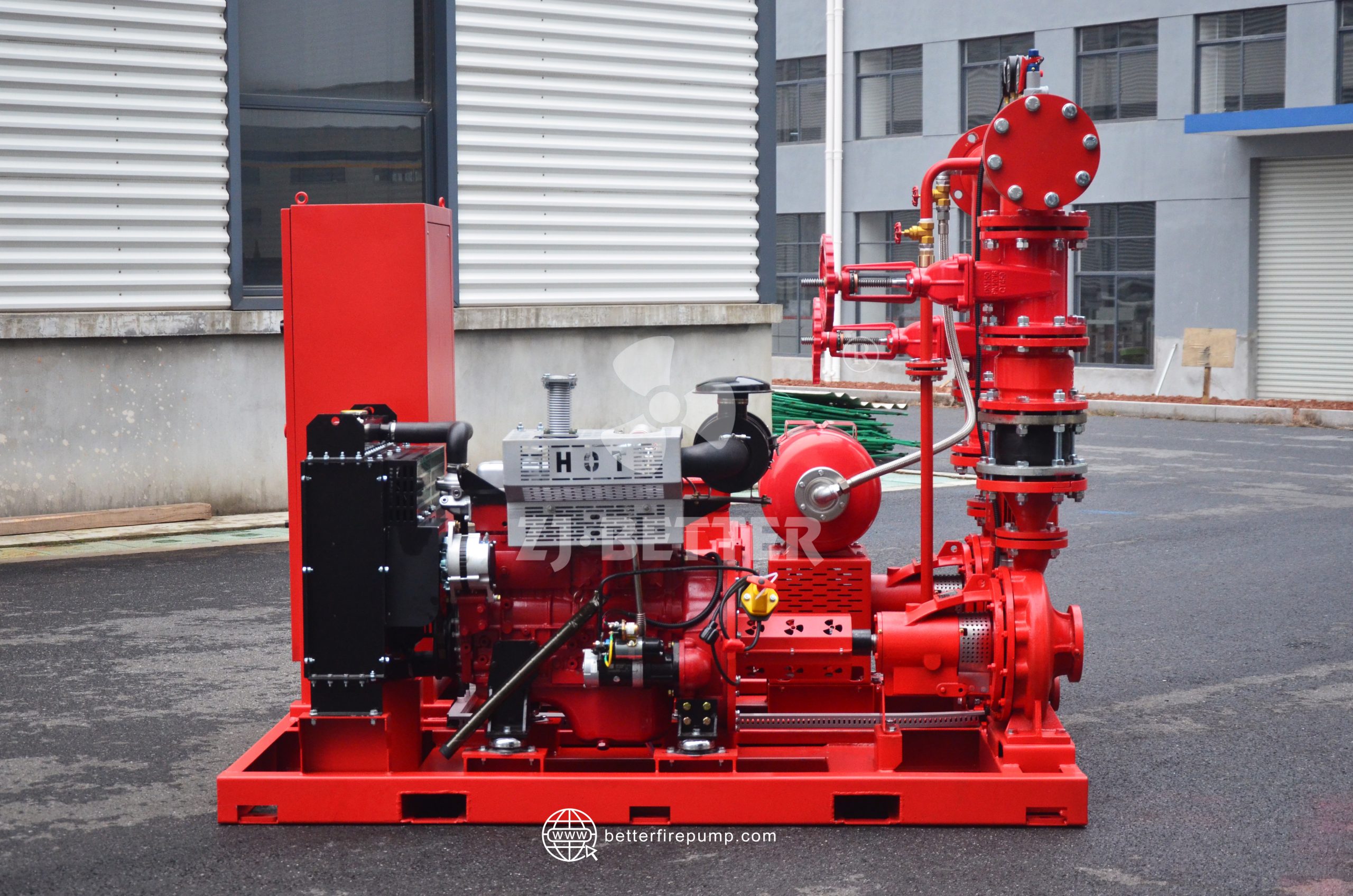

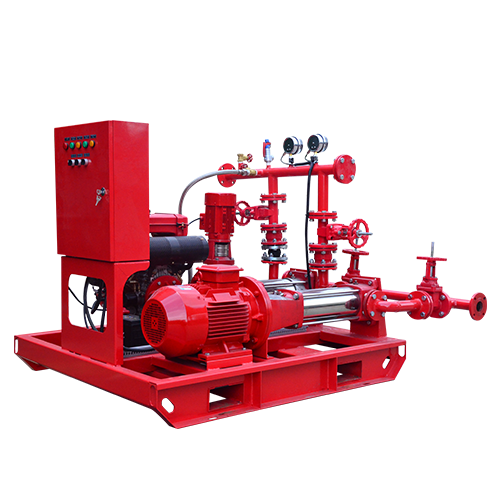

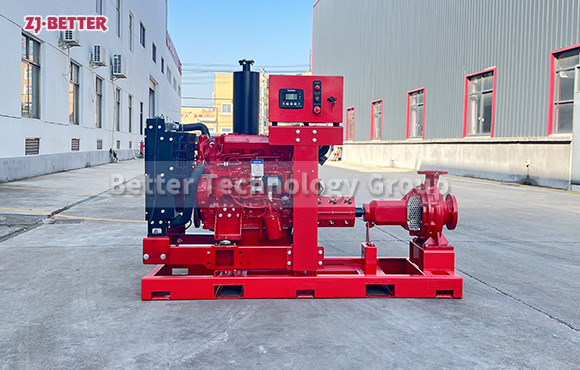

Standard EDJ Fire Pump Set From Chinese Manufacturer

The fire pump is actually a pump that needs to be used in fire protection. According to different classification methods, it can be divided into different types of pumps. With its characteristics of full sealing, no leakage and corrosion resistance, it is widely used in environmental protection, water treatment, fire protection and other departments to pump various liquids. The pump types of the system are similar, but the head and flow are different. The selection basis of the fire pump should be considered from five aspects according to the technological process and water supply and drainage requirements. Fire truck fire pumps are used in fire protection, water treatment, environmental protection and other departments to pump various liquids.

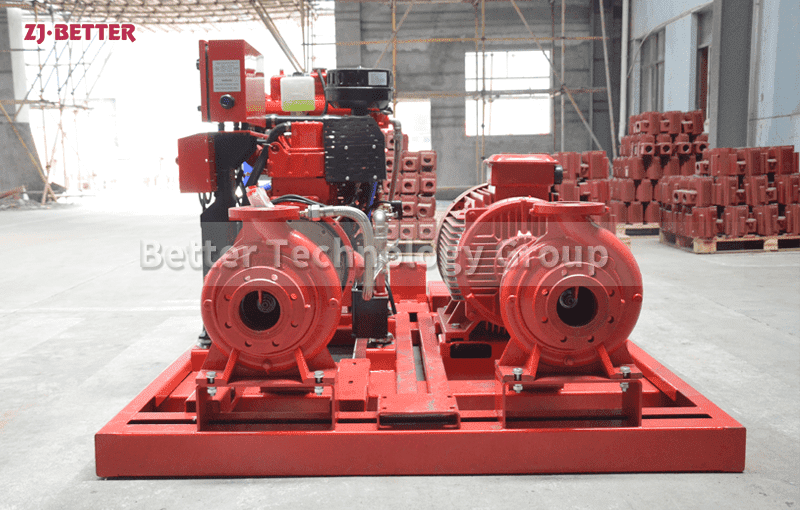

Components

1. Electric pump: kinds of end suction pump, split case pump, with brass impeller

2. Diesel pump: flow is the same with electric pump. It connects the pump set with high elastic coupling or universal joint,with brass impeller

3. Jockey pump: vertical, small flow, head is higher than electric or diesel pump, stainless steel impeller

4. Control panel: control the pumps automatically with overload, overcurrent protection.

5. Accessories: Suction pipe, Discharge pipe with flange, Battery, Gate valve, Check valve, Flexible expansion joints, Pressure switches, Pressure gauge, base frame etc.