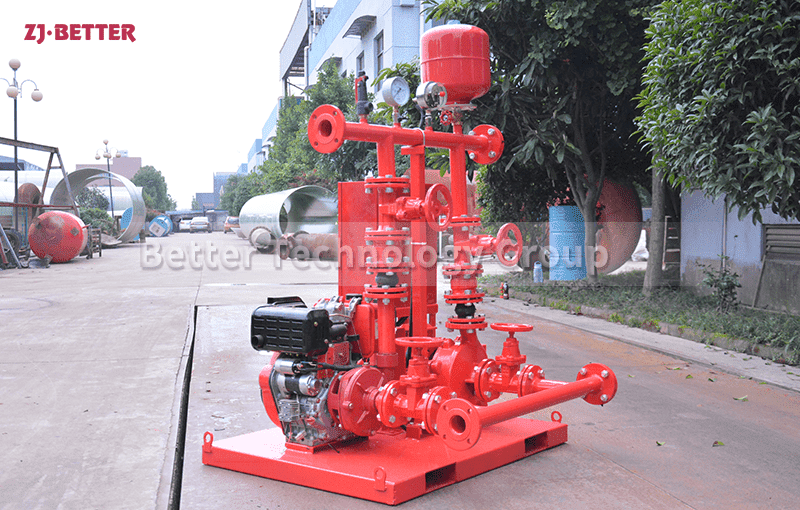

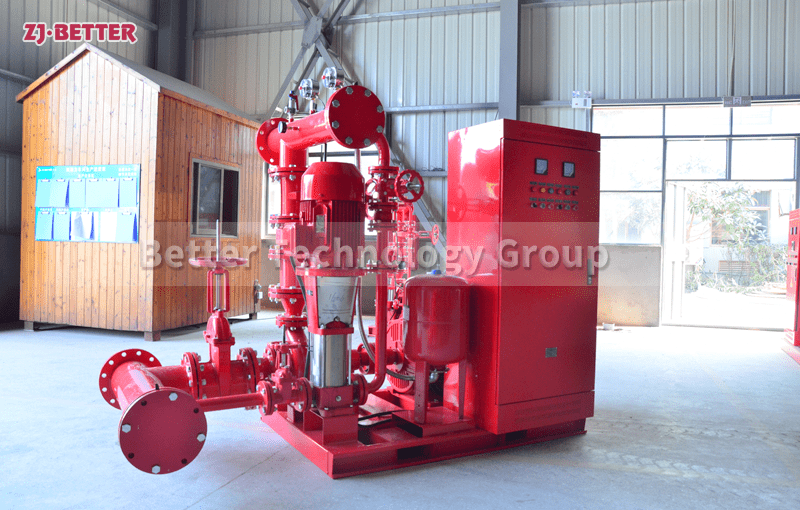

Start-up Function of Small Diesel Engine Fire Pump Set

Three start-up functions for diesel engines:

1. Manual start function: manual and automatic interlocking can be completed through the transfer switch, and the manual start function can be realized:

2. Automatic manual function: allow to start three times. If the startup fails for three times, it will issue a “startup failure alarm” and automatically exit the startup state. After a successful startup, the time from startup to rated load is 5-10-15S (depending on the unit capacity);

3. Emergency manual direct start function: When the automatic control device fails, the emergency manual direct start function can be realized.

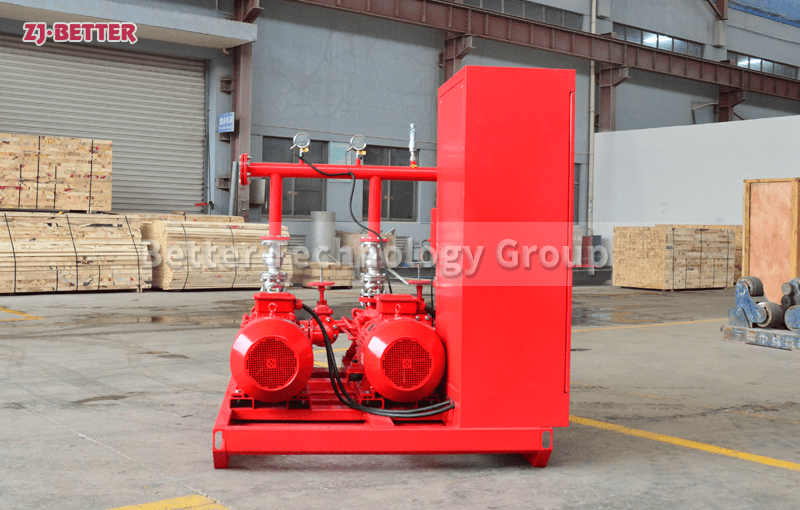

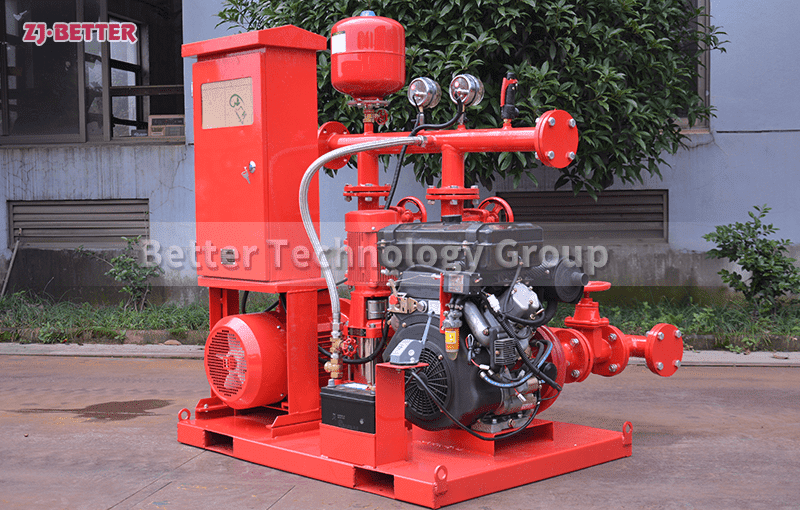

Main features of diesel engine fire pump:

1. Fully automatic start: After the diesel water pump diesel generator set receives a safety accident/pipeline network working pressure/power failure/or other starting data signals, it can start automatically within 15 seconds and operate the fund management load;

2. Automatic charging: the battery can be automatically charged by the working standard voltage or the diesel engine battery charging motor to ensure the successful start of the diesel generator set;

3. Fully automatic alarm: automatic alarm maintenance for difficult problems such as low air pressure and high temperature of diesel engine, alarm and shutdown at speed limit;

4. Fully automatic heating: make the diesel engine in the condition of embedded parts of the heat engine to ensure emergency work.