Summary of characteristics of diesel engine fire pump

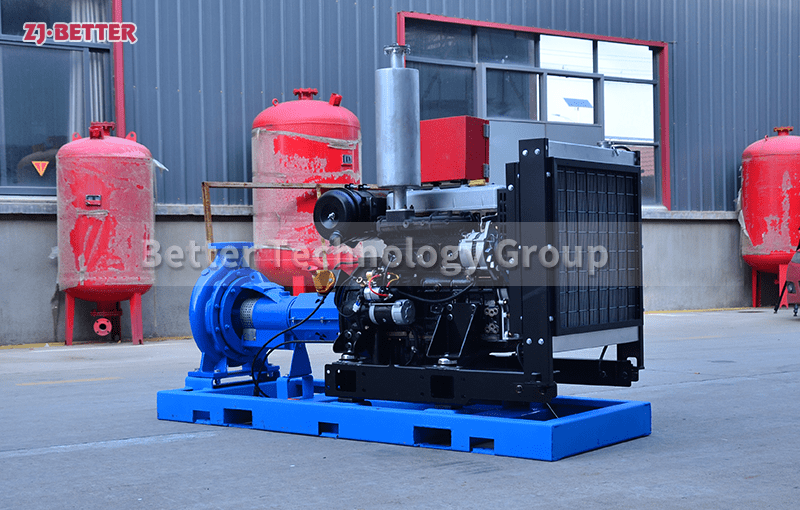

Diesel engine fire pump has high efficiency, long operating life and high reliability. It can be used in independent fire water supply system, some can be used in fire protection and domestic common water supply system, and it can also be used in construction, municipal, industrial and mining, water supply and drainage, ships, field operations, etc.

The characteristics of diesel engine fire pumps are summarized as follows:

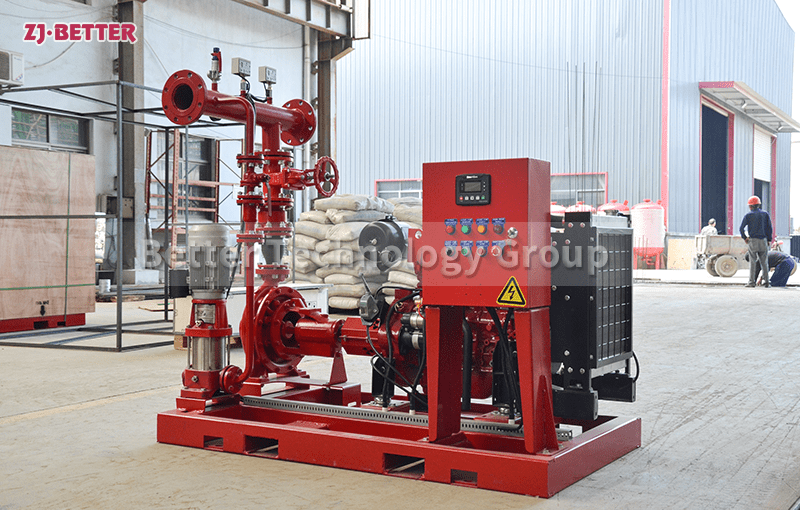

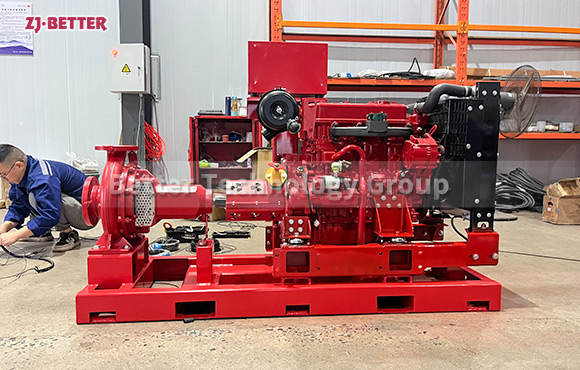

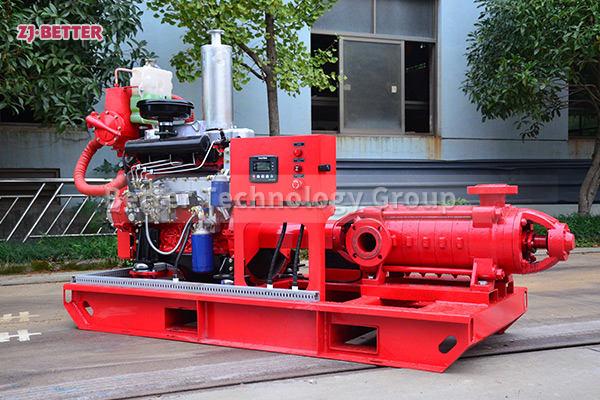

1. The diesel engine fire pump adopts the domestic first direct connection technology between the diesel engine and the water pump through an elastic coupling, which reduces the failure points, greatly shortens the starting time of the unit, and increases the reliability and emergency performance of the unit.

2. Automatic alarm protection for diesel engine low oil pressure, high water temperature and other faults, alarm and stop when over speed.

3. The diesel engine fire pump has the functions of remote measurement, remote signaling and remote control.

4. The battery can be automatically charged by the mains or diesel charging motor to ensure the smooth start of the unit.

5. Automatic preheating, so that the diesel engine is in the standby state of the hot engine to ensure emergency work.

6. The biggest difference between a diesel engine fire pump and an electric water pump is that it has its own independent power supply system—battery. Therefore, the start-up and operation of a diesel engine fire pump can be completely separated from the mains.

7. The diesel engine fire pump is usually used as a backup facility. Therefore, it will only start automatically when the fire signal comes, and the electric water pump fails or the power supply is cut off. When it has a device for starting the pump at ultra-low pressure, its matching electric water pump control cabinet should also have a device for starting the pump at ultra-low pressure, and the lower limit of the two pumps should have a certain pressure difference.