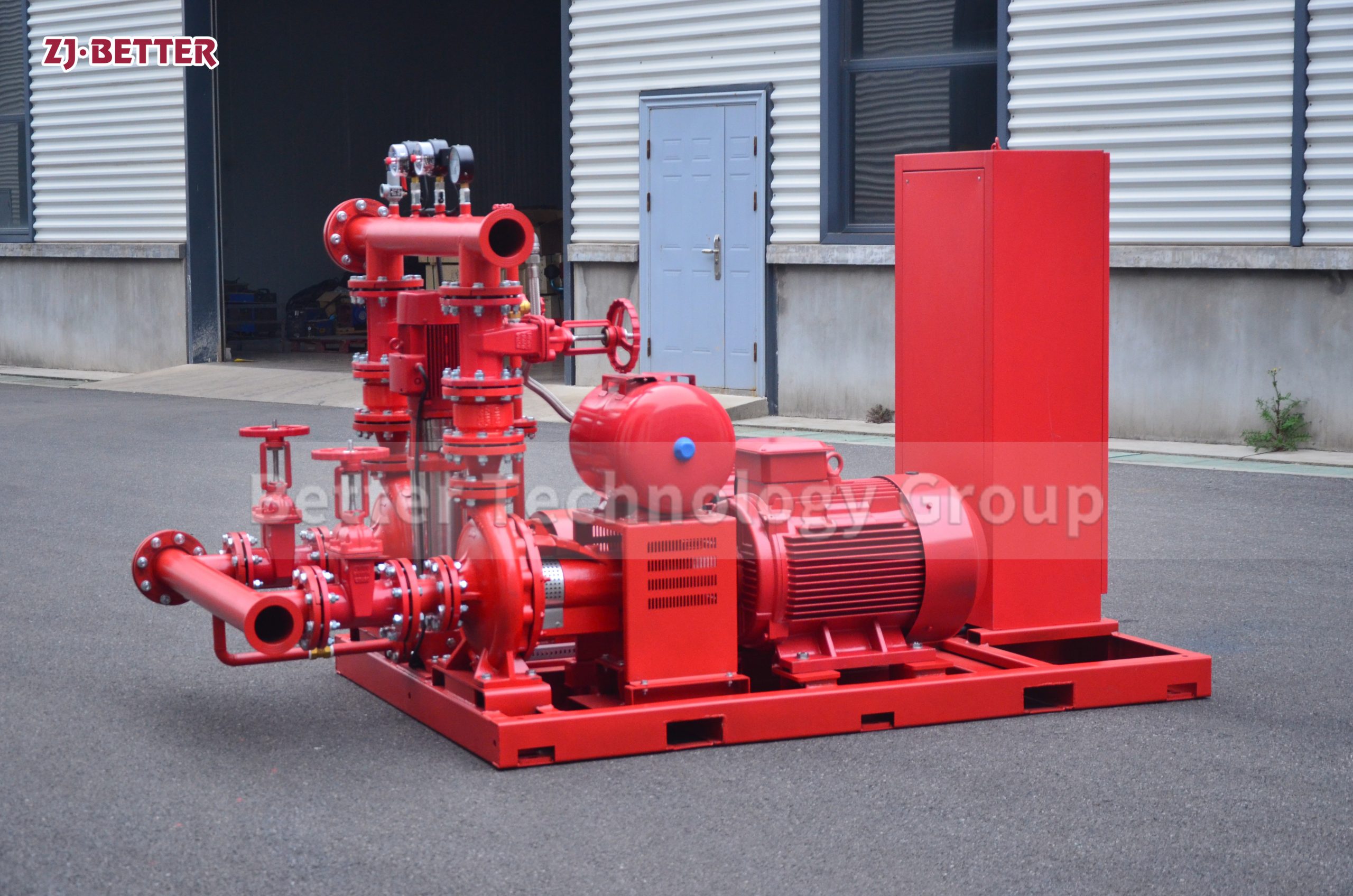

Swift Fire Protection: EDJ Pump with control panel

1.Flow:30-9000 GPM

2.Head: 3-20 Bar 40-300 psi

3.Power:Diesel & Electric Pump:1.5-710kw Jockey Pump:0.55-160kw

4.Speed:740-2900 r/min

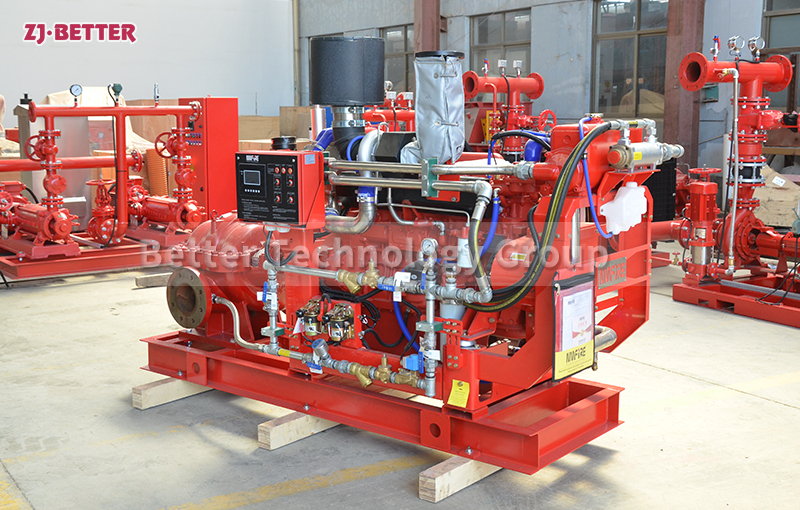

The EDJ Diesel Engine Fire Pump System is a powerful and reliable firefighting equipment designed for fire suppression and emergency rescue operations. It boasts high-performance capabilities in water extraction and pressure delivery, enabling rapid supply of large volumes of water. The system operates independently, ensuring its reliability even in challenging situations.

Types of pumps used for fire service include: End Suction Pump, Split Case Pump, Vertical Inline Pump and Vertical Turbine Pump.

1. Electric motor driven pump, can use single stage pump, horizontal split case pump, end suction pump,multistage pump.

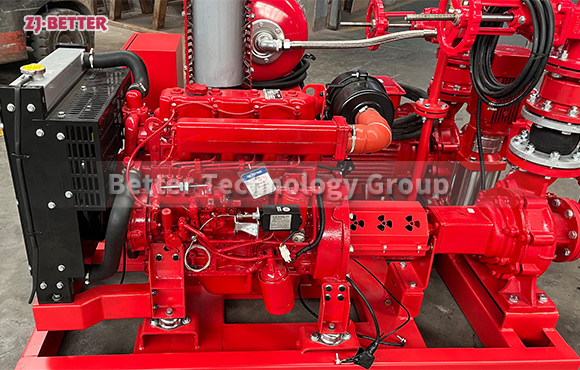

2.Diesel engine pump, with capacity and head equal to electric pump, with fuel tank, water tank, fan,control box.

3. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump.

4. Control panel: Auto Control of electric pump, diesel engine pump and Jockey Pump with overload, over current protection.

Whether you are part of a fire department, an industrial facility, a construction site, or a rural area, the EDJ Diesel Engine Fire Pump System is an indispensable firefighting asset. Count on the EDJ Fire Pump System to provide reliable support and swift containment of fires!