The difference between diesel fire pump and electric fire pump

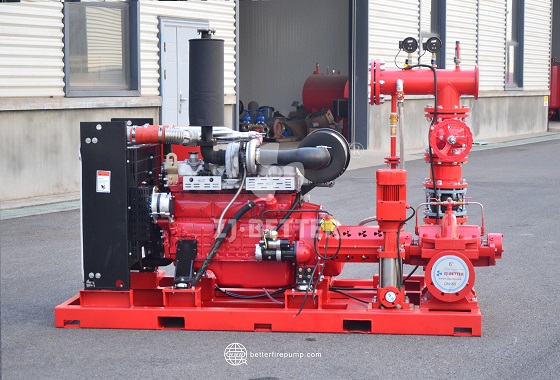

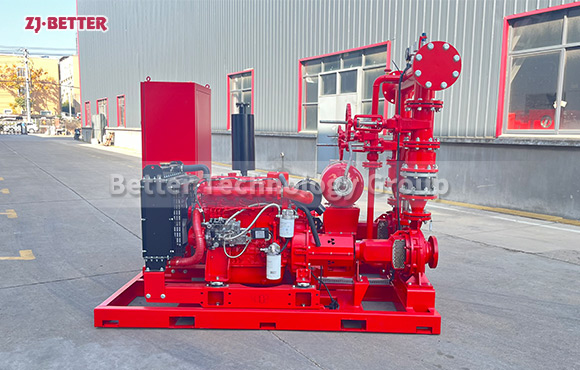

Diesel fire pumps are ideal for applications where a separate pump room already exists or where the pump room is located on an exterior wall. Facilities using diesel fire pumps include warehouses, aircraft hangars and industrial facilities. Since they have a larger footprint than electric fire pumps, they are not suitable for installations where space is small. Unlike diesel pumps, electric fire pumps can be located inside buildings. Office buildings and apartments are often equipped with electric fire pumps. In addition, upper floors sometimes install an additional electric fire pump above ground or basement to increase water pressure.

One of the important differences between electric and diesel fire pumps is cost, diesel fire pumps are more expensive to install as they require other items such as fuel storage tanks and exhaust ventilation, in terms of maintenance and lifetime costs, electric fire Pumps require electrical service and have higher electrical costs than diesel pumps. However, diesel fire pumps require regular inspections of the battery, oil level, cooling system, hoses and engine in addition to the weekly run test. Overall, diesel fire pumps are costly because of their high frequency of repairs and the number of items to maintain.