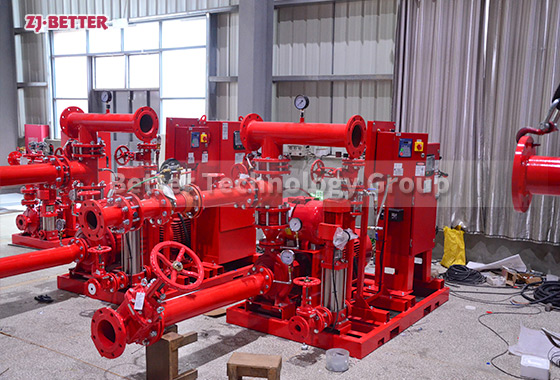

The fire pump equipment has a simple structure and stable performance

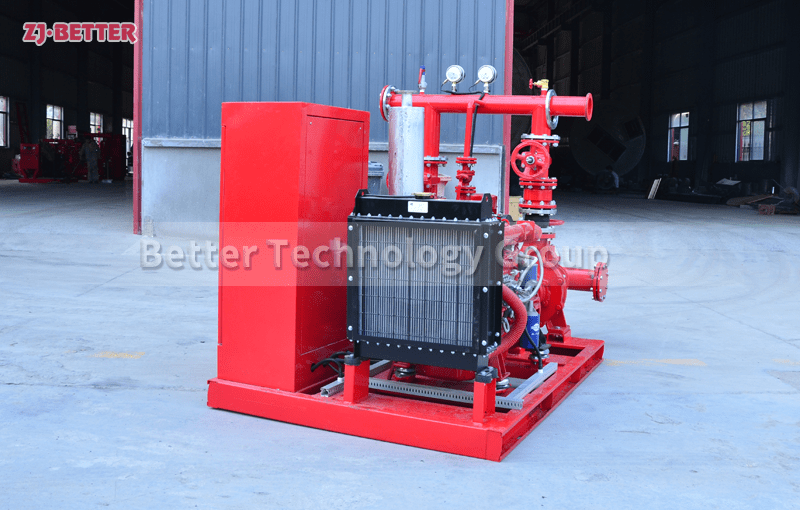

Fire pumps are widely used in our lives, such as in water treatment, fire safety and other departments. At the same time, it has the characteristics of full sealing, no leakage and corrosion resistance, and is widely used in life and production. In transportation and The storage aspect also shows its excellent characteristics, and it has become an indispensable device in many places now.

In people’s common sense, the fire pump is mainly used for water delivery in the fire protection system. As an indispensable tool for the fire protection system, the fire pump also has the characteristics of simple structure and stable performance, and its high speed, small size and high efficiency are also a major advantage. , it is precisely because of these advantages of high performance and low energy consumption that the safety and efficiency of the fire pump are far ahead of the pipeline tools of the same purpose.

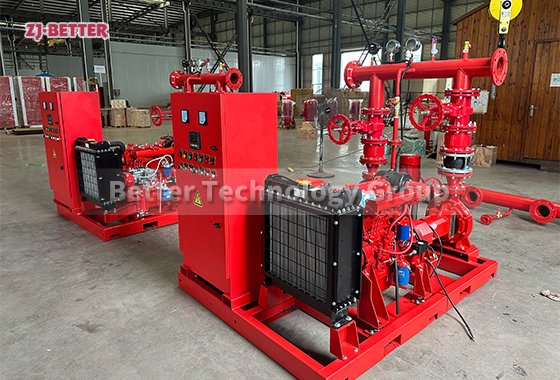

The application of fire pumps is not only in the fire protection system, but also a variety of fire pumps gradually show its superior strength in process production and urban construction, including industrial and urban water supply and drainage of high-rise buildings under pressure. The implementation and expansion of advanced high-end technologies, of course, the long-distance water delivery that we are familiar with, these aspects that we may ignore are inseparable from the application of fire pumps. Even the heating of bathrooms and the circulation of hot and cold water in boilers depend on the assistance of fire pumps of some practical type.