The function of the diesel fire pump is very powerful

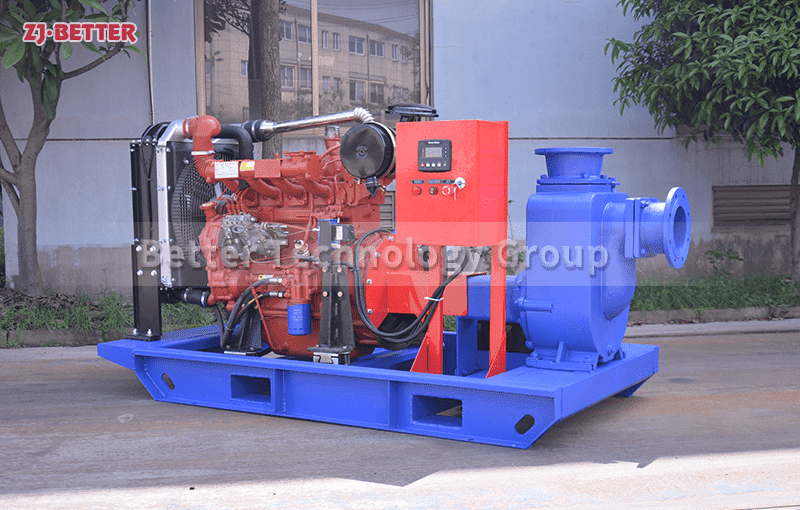

The diesel engine fire pump set has the characteristics of good starting characteristics, strong overload capacity, compact and reasonable structure, convenient maintenance, simple and reliable use, etc. The unit is equipped with protection functions such as overspeed, low oil pressure, three start failures, high water temperature, low oil level, and low battery voltage. At the same time, it can be connected with the customer’s automatic fire alarm device or the centralized control cabinet of the fire protection system to realize the function of remote monitoring.

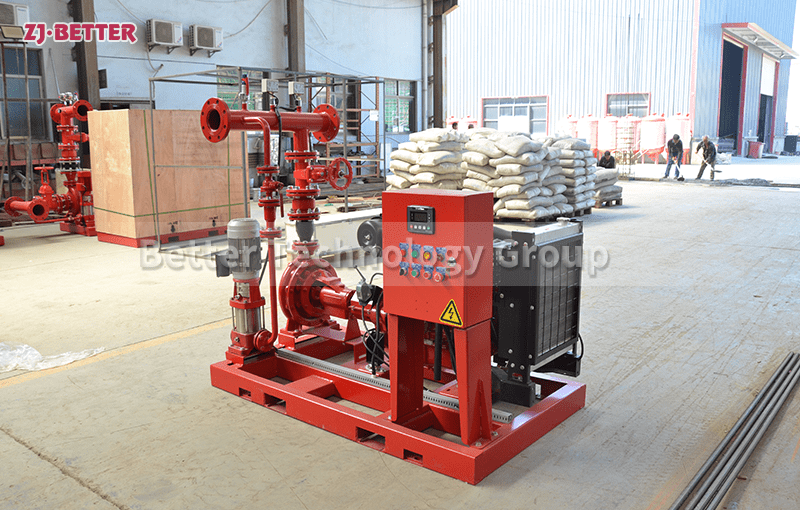

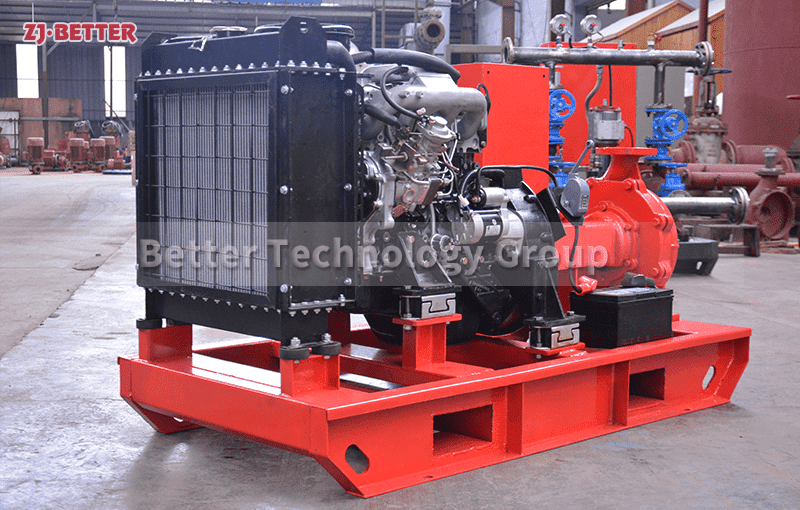

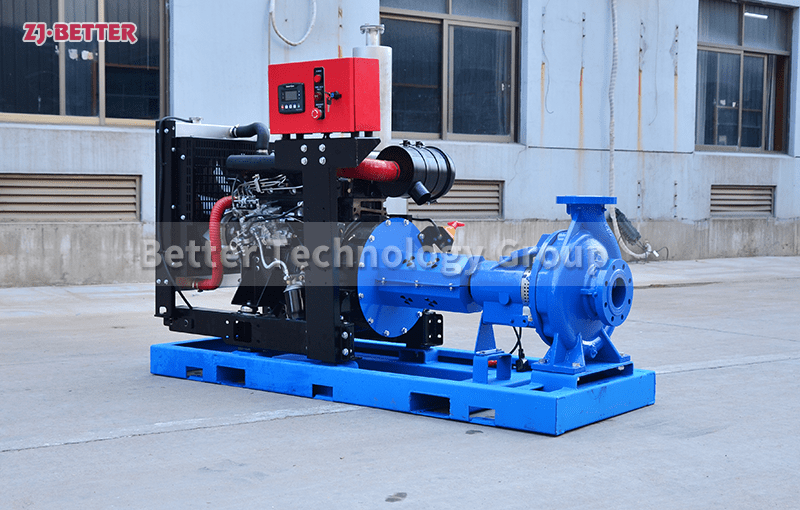

Diesel fire pump is composed of diesel engine, chassis, cooling water tank and fan, high elastic coupling, water pump, diesel tank and control panel and other equipment. The water pump is directly connected with the diesel engine through a highly elastic coupling or a diaphragm coupling, and is installed on the common channel steel chassis. The cooling of the engine is carried out by the fan driven by the engine to cool the radiator water tank. The entire cooling system constitutes a closed cycle, and the water tank is also installed on the chassis. The control panel and the unit are separated, and the two are connected by control cables, signal cables and power cables. The oil tank of the unit with diesel engine power below 200KW is directly installed on the unit, and the unit with power of more than 200KW adopts split oil tank. The basic unit is suitable for fire protection systems with inverted water sources.