The importance of diesel engine fire pumps in fire protection

Diesel engine fire pumps are relatively common in life, and their performance requirements are relatively high. In normal use, more attention must be paid to maintenance to prolong the service life of the pump. Because diesel fire pumps are not omnipotent, there will be some problems in daily use, so when choosing equipment, we must pay attention to whether the quality of the equipment has reached the national standard. As fire equipment, all kinds of equipment must be Ensure performance, avoid affecting use in disasters and delay rescue.

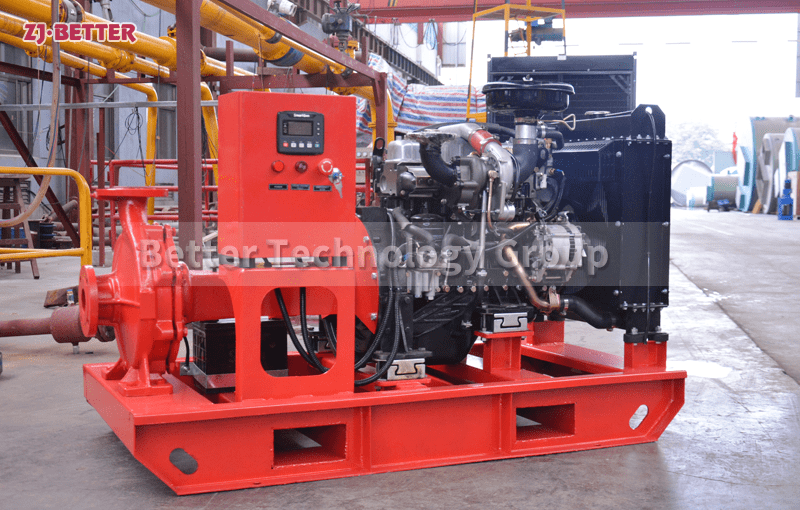

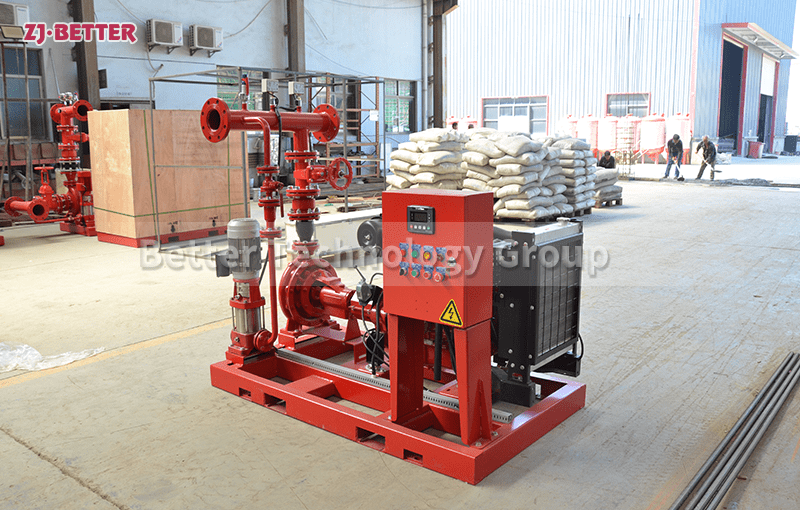

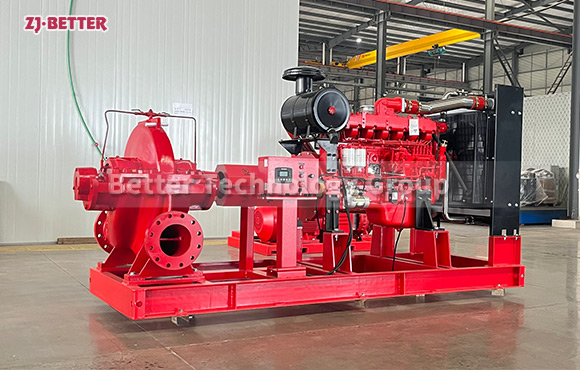

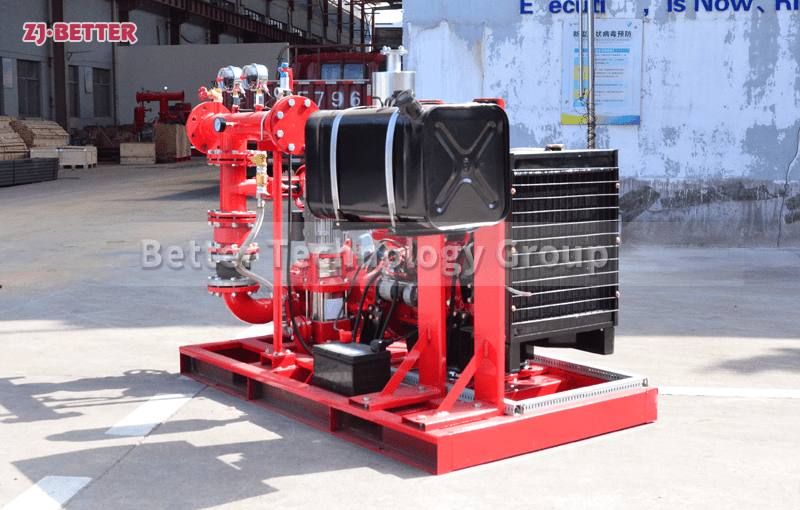

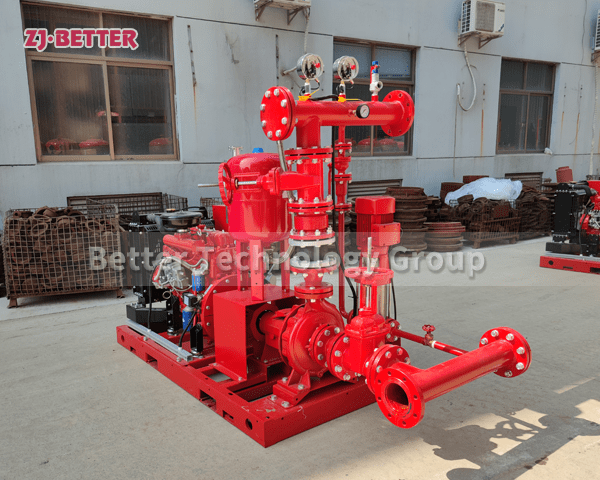

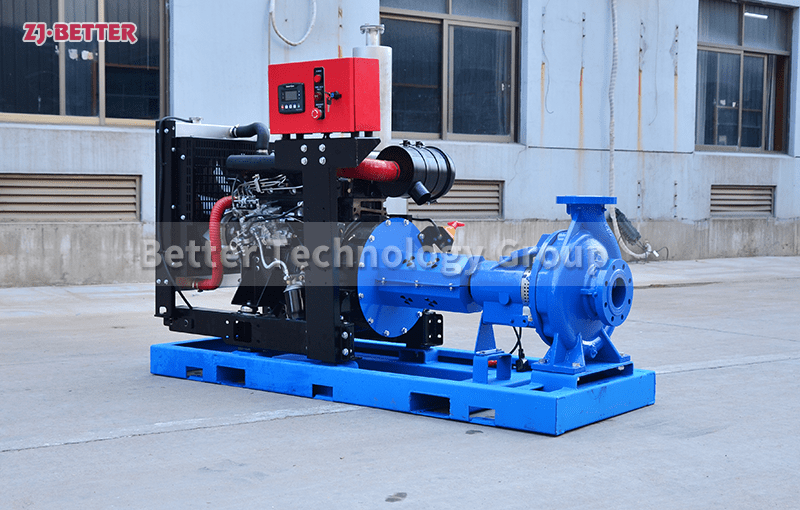

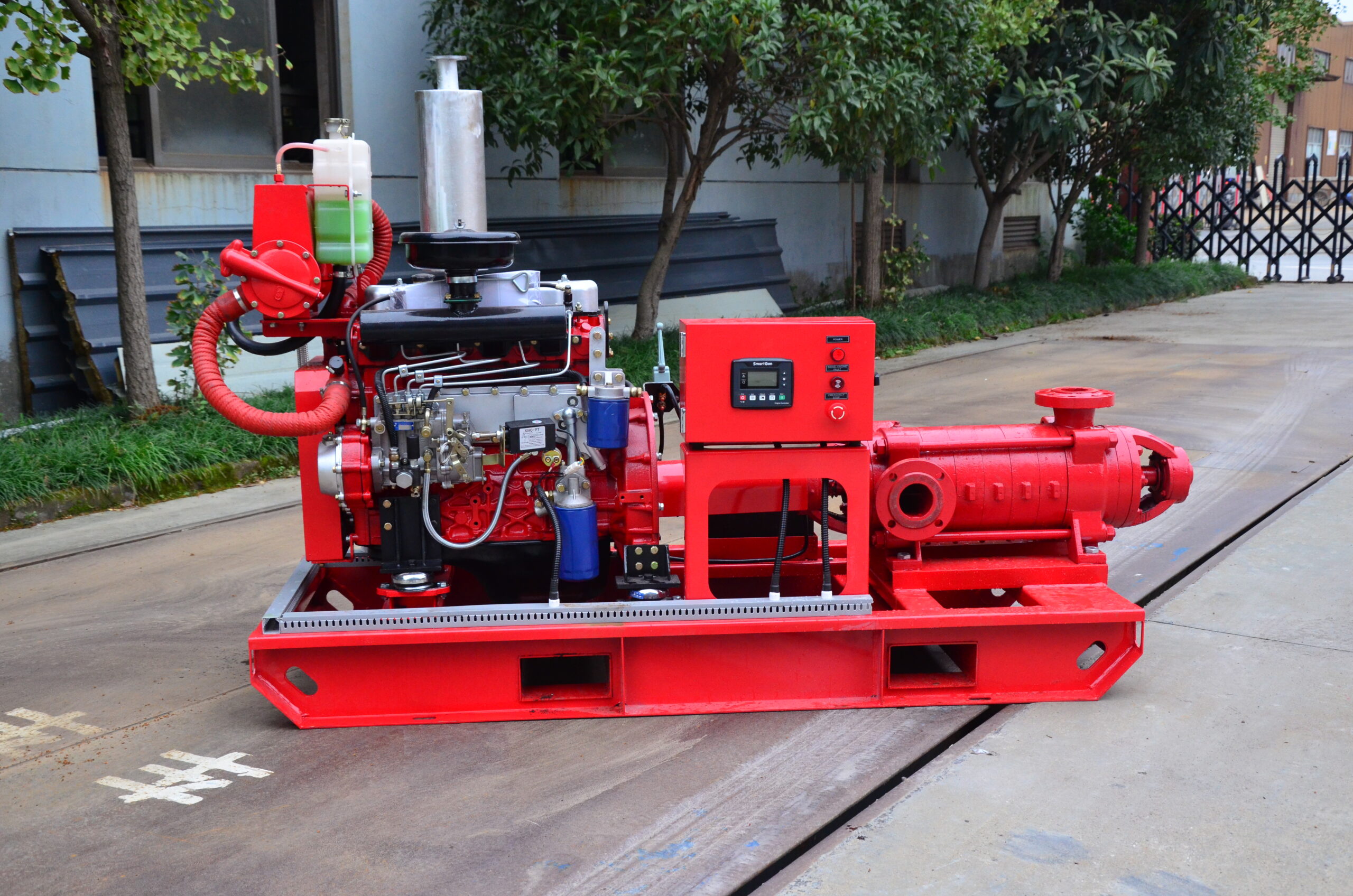

XBC basic unit is composed of diesel engine, chassis, cooling refrigerator and fan, high elastic coupling, water pump, diesel tank and control panel and other equipment. The water pump is directly connected with the diesel engine through a highly elastic coupling or a diaphragm coupling, and is installed on the common channel steel chassis.

The cooling of the engine is carried out by the fan driven by the engine to cool the radiator water tank. The entire cooling system constitutes a closed cycle, and the water tank is also installed on the chassis. The control panel and the unit are separated, and the two are connected by control cables, signal cables and power cables. The basic unit is suitable for fire protection systems with inverted water sources.