The importance of diesel engine fire pumps under powerless conditions

Diesel engine fire pumps are still common in life, and their performance requirements are relatively high. In normal use, pay more attention to maintenance, so that the service life of the pump can be extended. Because the diesel fire pump is not a panacea, all problems will occur in daily use, so you must pay attention to whether the equipment quality meets the country’s compliance standard when choosing a device. As a fire protection device, all kinds of equipment must be all equipment. Ensure performance, avoid affecting use in disaster conditions, and delay rescue.

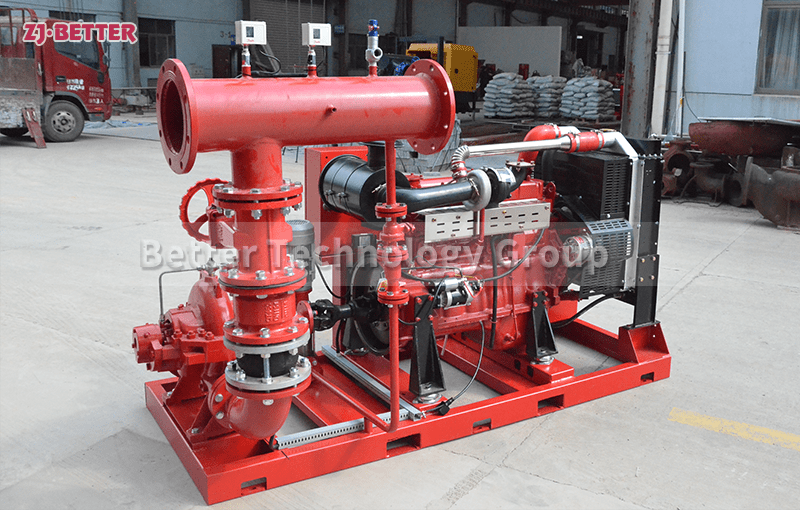

The full name of the diesel engine fire pump we usually say is engineering diesel engine fire pump group, which can automatically charge, automatically start, and automatic alarm and automatic warm -up. It is very reliable to use. The advantages and preparations you need to do before use.

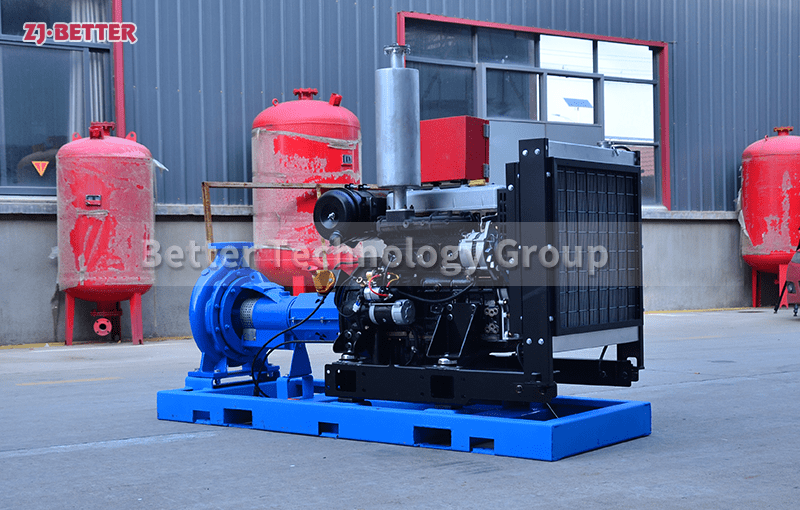

The biggest difference between the characteristic of the diesel engine fire pump is the biggest difference between the diesel engine fire pump electric water pump is that it has its own independent power supply system -battery, so the start and operation of diesel engine fire pumps will not completely depend on urban electricity.

Diesel engine fire pumps are usually used as spare facilities. Therefore, only when fire signals come, and the electric water pump is faulty or the power supply is turned off, it is automatically started. When it has a device with an ultra -low -voltage pump, and its supporting electric water pump control cabinet, there should also be a device with an ultra -low voltage enable pump, and the lower limit of the pump of the two should have a certain pressure difference.