The Importance of Diesel Fire Pumps When No Power Is

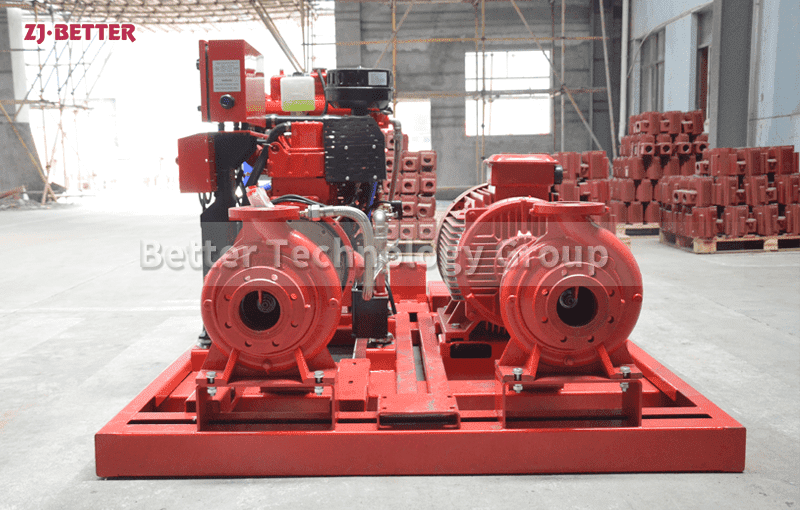

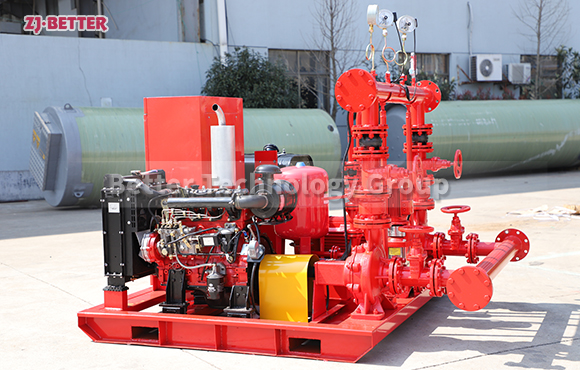

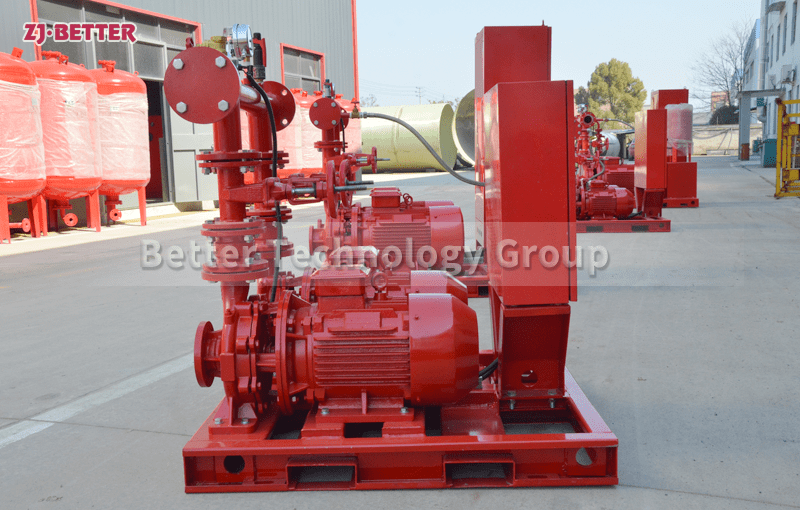

The diesel engine fire pump is usually used as a backup facility, so it will only start automatically when the fire signal comes, and when the electric water pump fails or the power supply is cut off. When it has an ultra-low pressure start-up device, the matching electric water pump control cabinet should also have an ultra-low-pressure start-up device, and the lower limit of the two pumps should have a certain pressure difference. Of course, according to customer requirements, design a control system that is more suitable for customer needs.

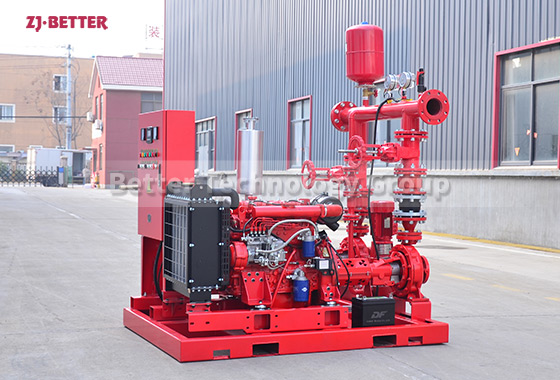

Since the operation of the electric fire pump is inseparable from electricity, and the power supply is often cut off at the scene of the fire accident or the power supply is automatically closed due to the fire, even if we are equipped with a dual power supply switching device, it is really impossible to ensure that the power grid must be normal when the fire alarm signal comes.

Therefore, starting and running a diesel engine fire pump completely disconnected from the grid becomes the preferred equipment for backup fire protection facilities! The driving power of diesel engine fire pumps is completely different from that of electric water pumps, so their daily protection and treatment are also different in many places! The characteristics of diesel engine fire pump: The biggest difference between diesel engine fire pump and electric fire pump is that it has its own independent power supply system – battery, so the start and operation of diesel engine fire pump can be completely separated from the mains.