The jockey fire pump set is in working condition for a long time

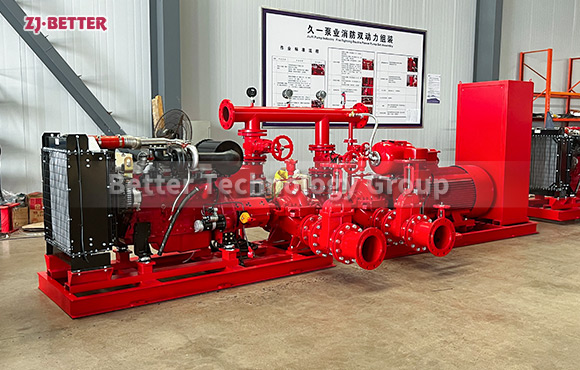

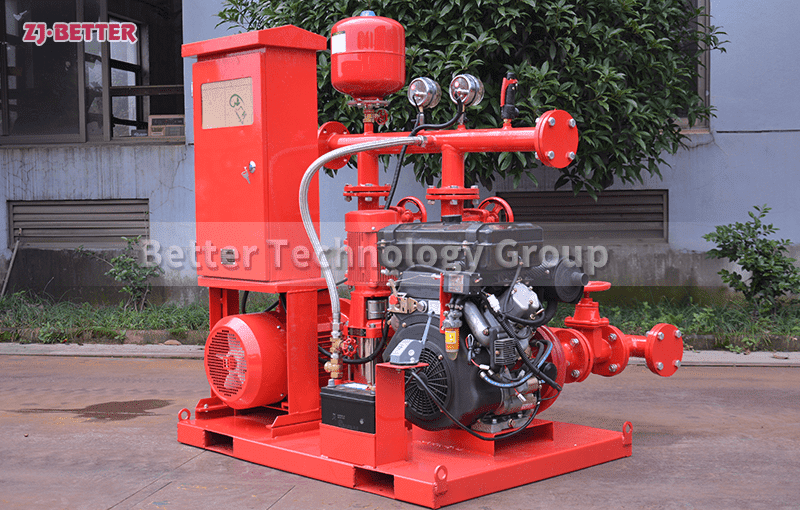

The jockey pump of the jockey fire water supply system must be kept running at ordinary times to maintain the pressure of the pipe network. When a fire occurs, it should still be able to run for a period of time until the main fire pump is started. It must be set according to the main and standby pumps. pressure pump. Due to the need for the stabilizing pump to keep running, energy is wasted, and the stabilizing pump is in working condition for a long time.

The fire jockey pump cooperates with the main pump to take water from the pool and deliver it to the system to maintain the system pressure. It is called normal high pressure or stable high pressure, quasi-high pressure system, and it is a system without a high fire water tank. The jockey pump of the high-pressure fire-fighting water supply system must keep running at ordinary times to maintain the pressure of the pipe network. When a fire occurs, it should still be able to run for a period of time until the main fire pump is started. Pump. Since the regulator pump needs to keep running, energy is wasted, and the fire regulator pump is in working condition for a long time, so there are high requirements on its service life.