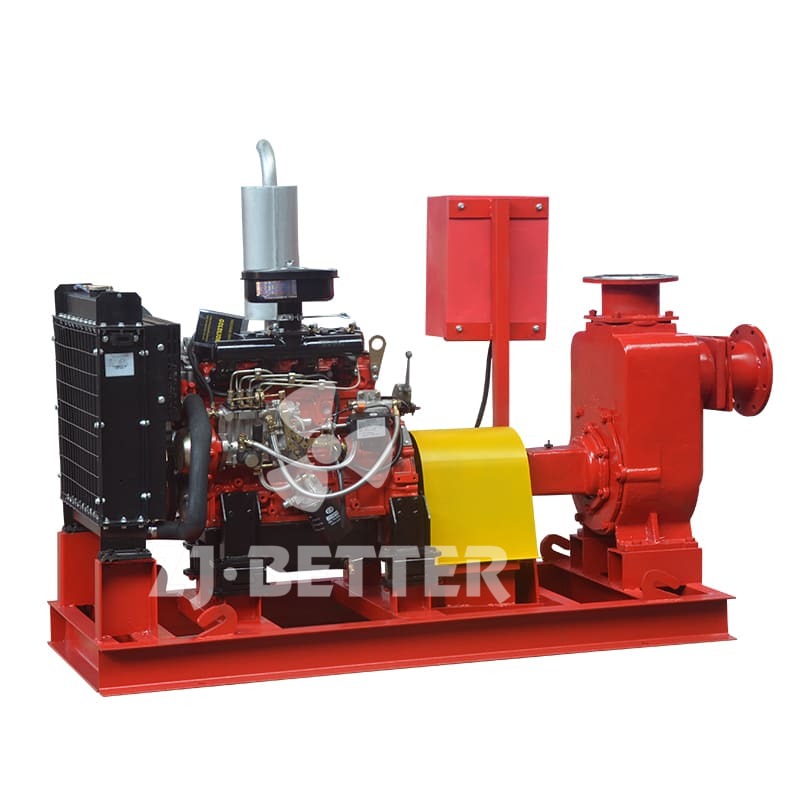

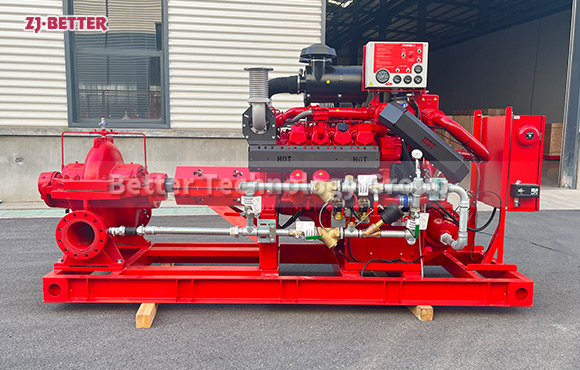

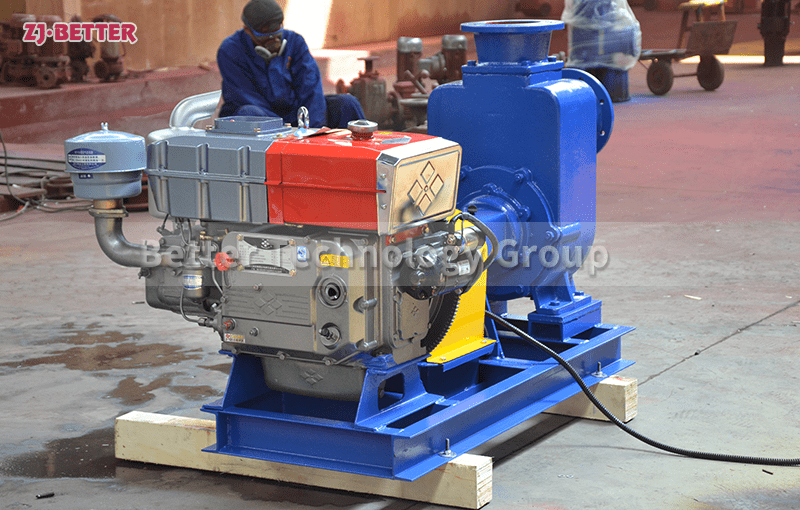

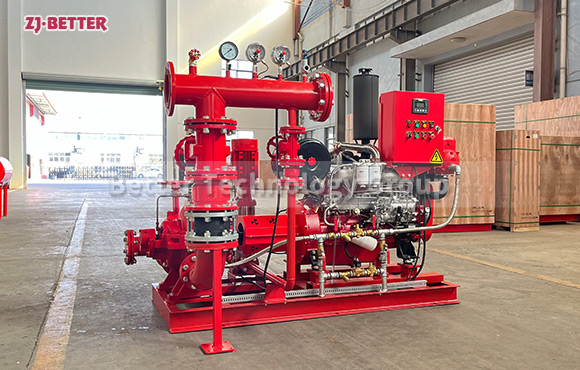

The self-priming pump

The self-priming pump is a self-priming centrifugal pump. It has the advantages of compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long service life, and strong self-priming capacity. There is no need to install a bottom valve in the pipeline. Before operation, it is only necessary to ensure that there is a certain amount of liquid in the pump. Self priming pumps of different materials can be used for different liquids.

The working principle of self-priming pump is to fill the pump casing with water (or there is water in the pump casing itself) before starting the pump. After startup, the high-speed rotation of the impeller causes the water in the impeller channel to flow to the volute. At this time, a vacuum is formed at the inlet to open the inlet check valve. The air in the suction pipe enters the pump and reaches the outer edge through the impeller channel.

After more than 10 years development, BETTER PUMP has won awards including all kinds of certificates awards by governments institutional and society. As we have professional R&D team, our products has got the Certificate of Utility Model Patent and Certificate of Design Patent. And our factory has got Production License, authentication from SGS, Export License from government. We are also have many honor, the enterprise of Vice Chairman of Quzhou Network Association, the cooperative enterprise with Quzhou colleges and universities. We are also a member of Wenzhou Commerce, Quzhou disabled people internship foundation. All of our products accord with machinery industries standard JB/T5118-2001.