The vertical turbine pump set

The long-shaft submerged pump is suitable for conveying belt particles, high viscosity, strong acid, alkali, salt, strong oxidant and other corrosive media. The new submerged pump is suitable for conveying various light media such as flammable and explosive. The shell, outlet pipe and overflow parts of the traditional submersible pump are all made of corrosion-resistant materials. The motor part is placed on the liquid surface, and the pump part is placed under the liquid surface. It has strong corrosion resistance, no blockage and high temperature resistance. Features. The pump body, motor and overcurrent parts of the new type of submersible pump are all made of special materials. The motor part and the pump part are coaxially connected and placed under the liquid surface. Features.

Zhejiang Better Pump Industry Co., Ltd.

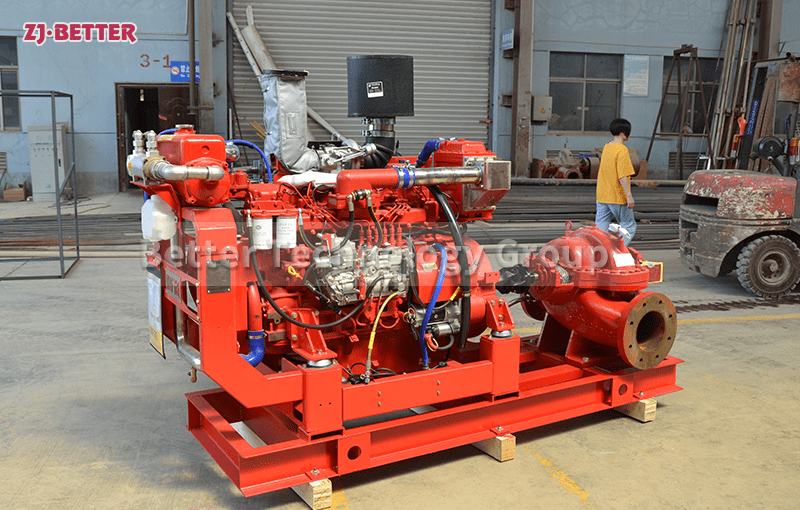

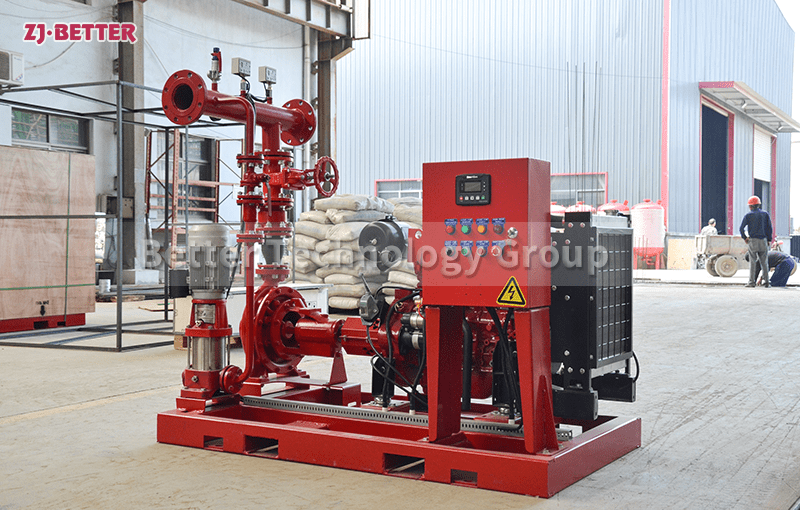

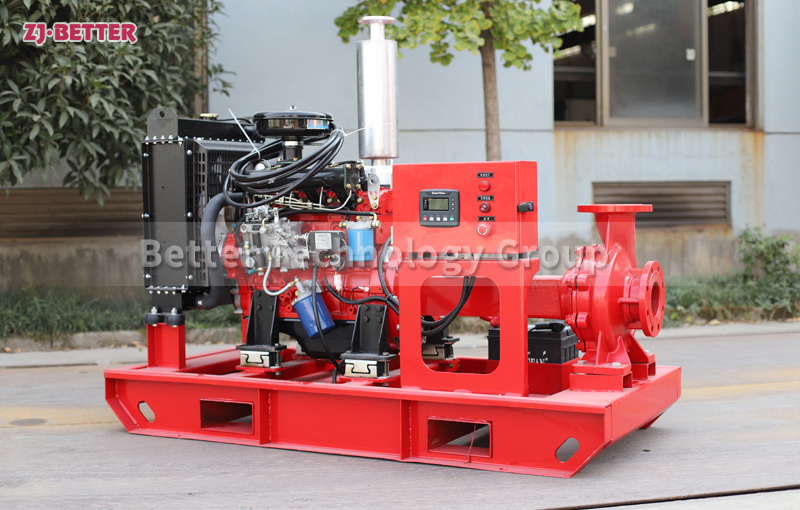

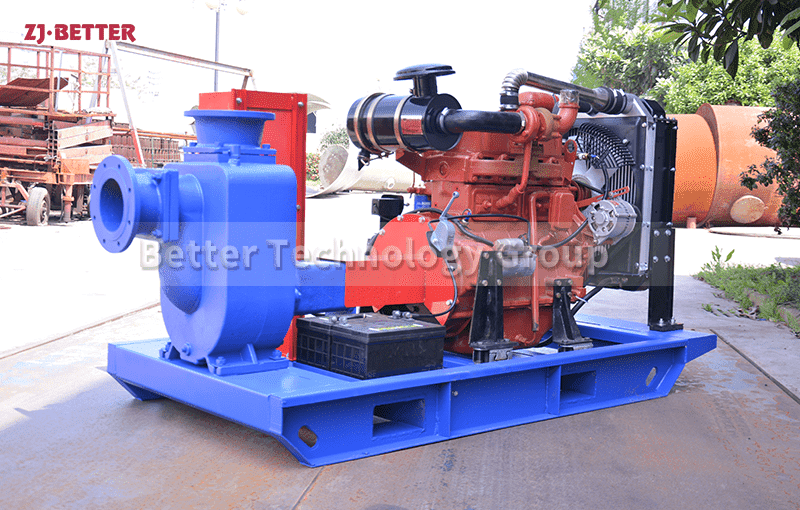

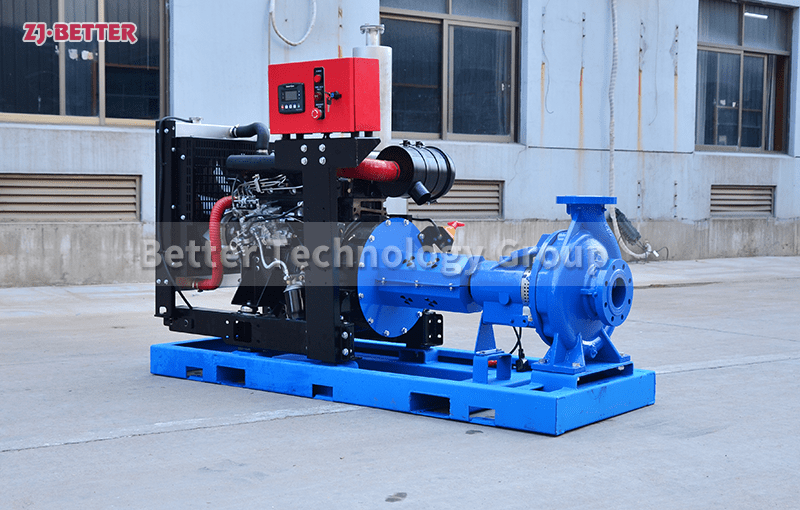

The company’s main products are submersible fire pump, city emergency drainage pumps, diesel fire pumps, gas top pressure fire water supply equipment, catering oil-water separation equipment, tank fire booster pump integrated regulator water supply equipment, B series submersible sewage pump, AST Building Civil dedicated

sewage pump series, WQ, QW series submersible sewage pump, ISG, IRG, IHG, ISGD series vertical pipeline pump, ISW, ISWD series of horizontal centrifugal pumps, DL Vertical multi-stage pump, GDL type will be demolished multi-stage pipeline pump, LG, LG-B type will be demolished high-rise building water supply multi-stage pumps. The company’s main products are in line with high-tech fields supported by the state.