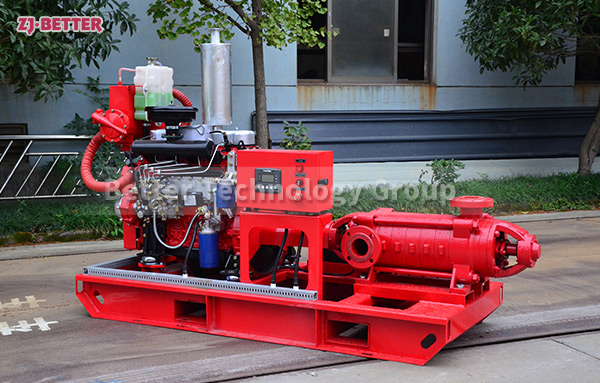

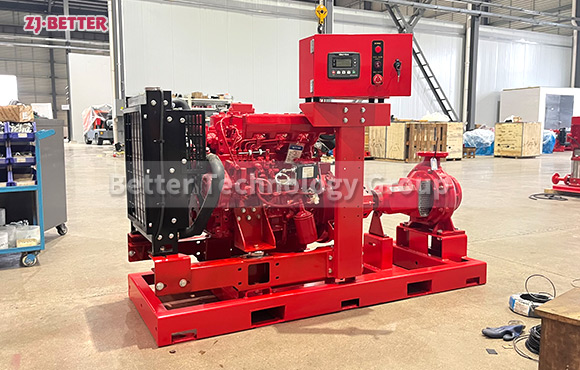

The XBC-S 11.5/160 320kW Diesel Engine Fire Pump is a high-performance firefighting solution

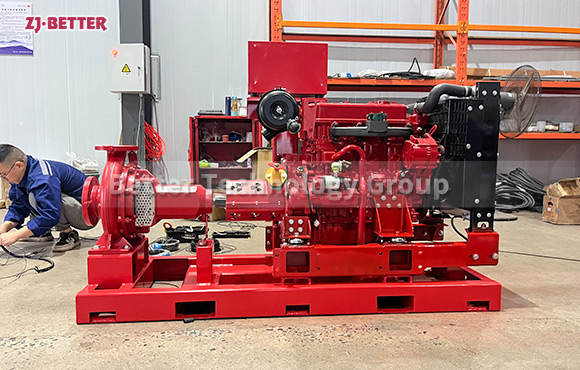

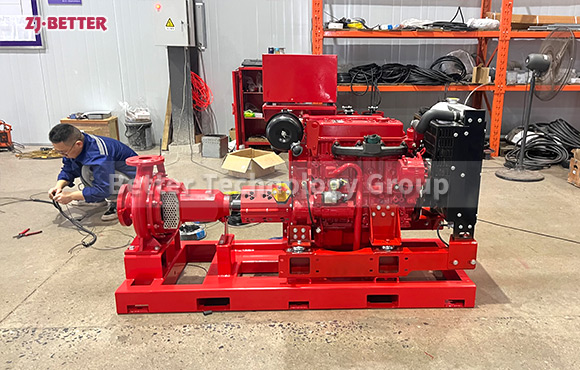

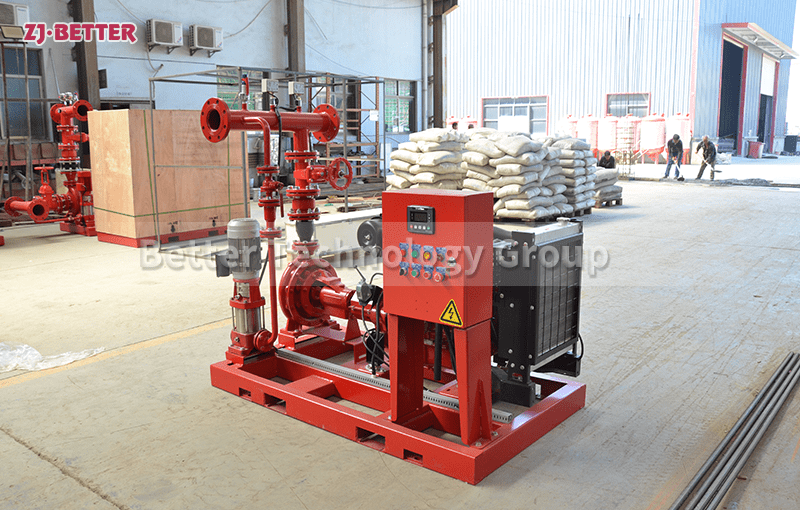

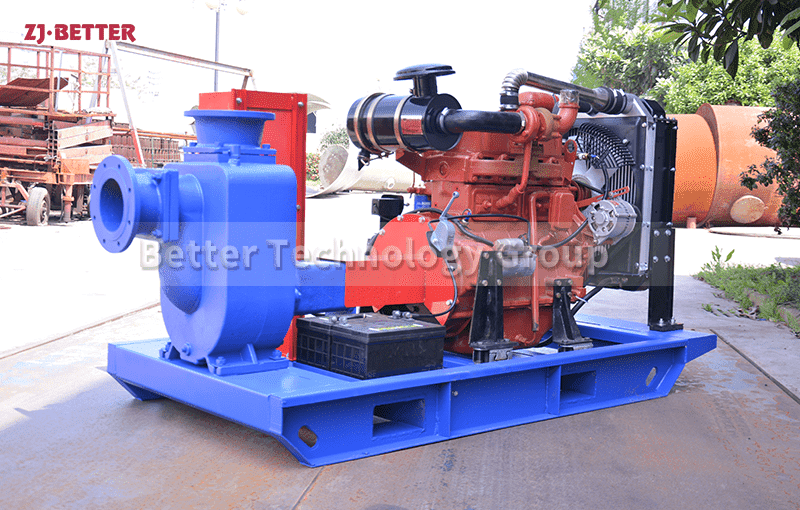

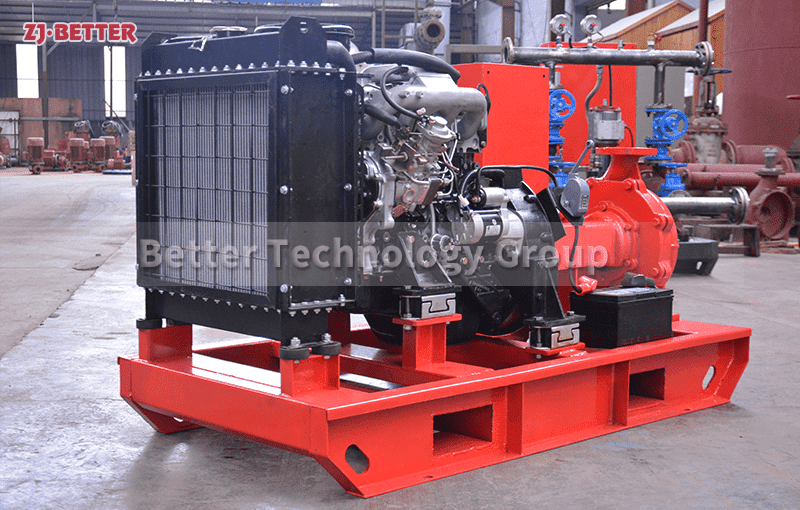

The XBC-S 11.5/160 320kW Diesel Engine Fire Pump is a cutting-edge and high-performance firefighting solution designed to provide exceptional power, efficiency, and reliability in fire suppression operations. This robust fire pump is specifically engineered to meet the demands of challenging fire scenarios, ensuring the swift and effective extinguishing of fires in various industrial, commercial, and residential settings.

Key Features of the XBC-S 11.5/160 320kW Diesel Engine Fire Pump:

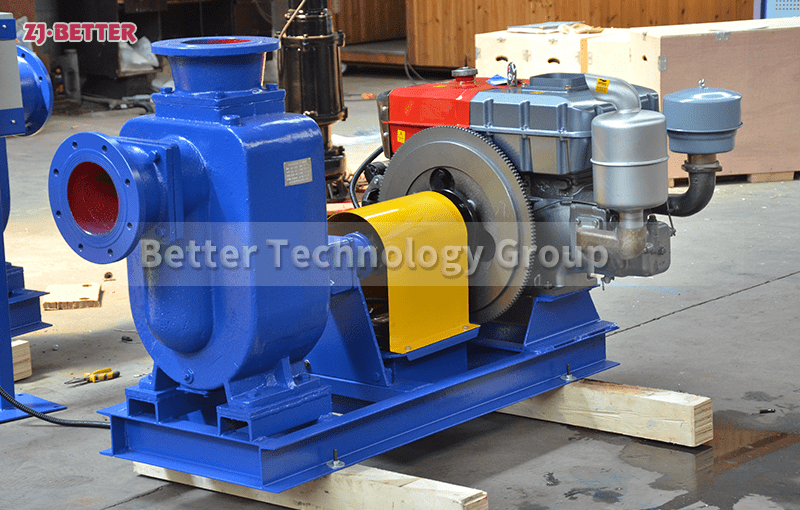

1.Impressive Power Output: Equipped with a 320kW diesel engine, the XBC-S fire pump delivers substantial power, enabling it to handle large-scale fires and provide a consistent and powerful water supply for firefighting operations.

2.Efficient Water Flow: The 11.5/160 rating signifies its impressive water flow capacity of 11.5 liters per second at a pressure of 160 meters, ensuring a strong and steady stream of water to suppress fires effectively.

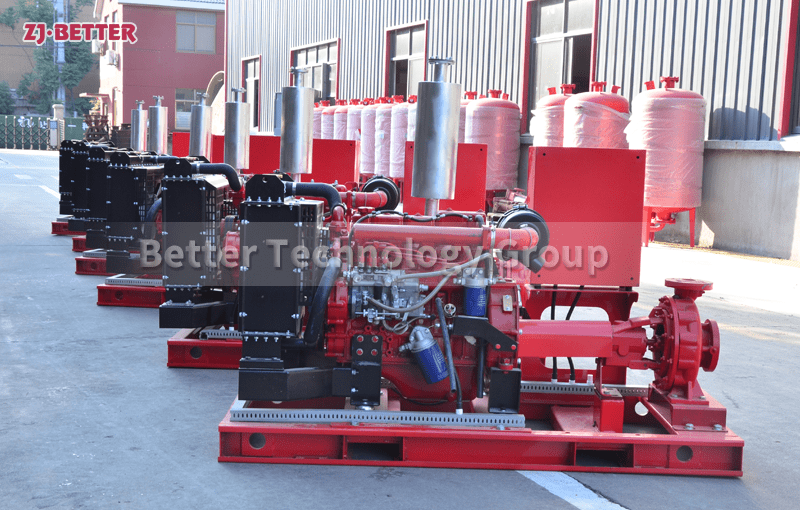

3.Sturdy and Durable Construction: Built with durable materials and advanced engineering, the XBC-S fire pump is designed to withstand harsh conditions and operate reliably in demanding environments, ensuring long-term performance and durability.

4.Intelligent Control System: The fire pump features an intelligent control system that enables automatic start-up, monitoring, and shutdown, optimizing operational efficiency and reducing the workload for firefighters.

5.User-Friendly Design: With its user-friendly interface and intuitive controls, the XBC-S fire pump is easy to operate and requires minimal training. This enables firefighters to quickly and efficiently respond to fire emergencies.

6.Versatile Application: The XBC-S 11.5/160 320kW Diesel Engine Fire Pump is suitable for a wide range of applications, including industrial facilities, high-rise buildings, warehouses, and more. It ensures reliable and powerful water supply, empowering firefighters to combat fires effectively.