There are many types of fire pumps to deal with more fire water environments

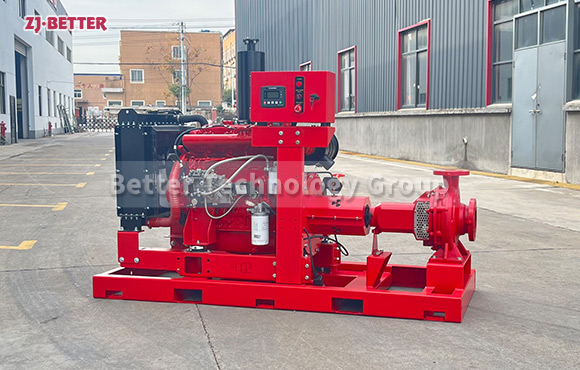

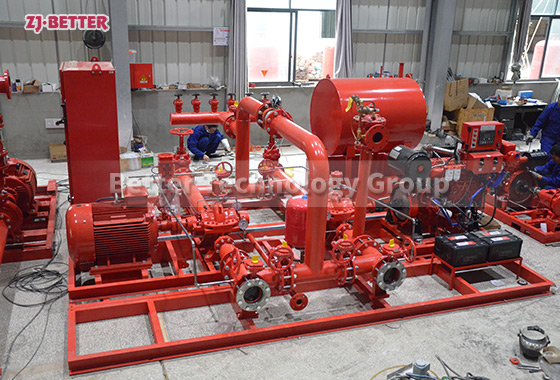

There are many types of fire pumps to deal with more fire water environments. Fire pumps are used in buildings, factories, storage and other places, and the performance requirements and quality requirements are different. The commonly used types of fire pumps are vertical electric fire pumps, diesel fire pumps, horizontal single-stage fire pumps, vertical single-stage/multiple Level fire pumps and horizontal double-suction fire pumps, etc., the specific head, flow and power are selected according to different projects.

There are many applications for fire pumps, and different motors are selected according to the flow rate and head size. The commonly used motors include electric motors and diesel engines, and domestic and foreign brands can match the application. The fire pump can choose vertical or horizontal structure according to the pipeline requirements, and the head size is also different. Finding a professional pump factory or company can reduce the probability of wrong selection, and at the same time take into account the on-site installation requirements and pipeline design.