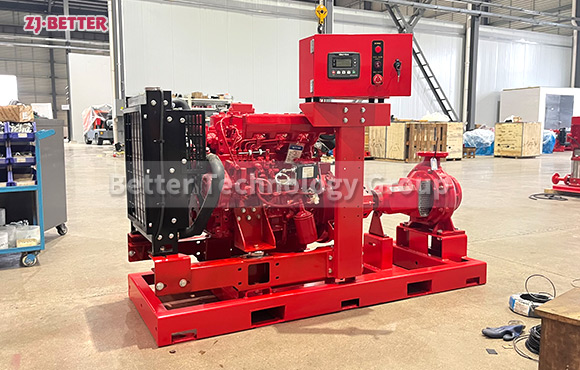

Three starting functions of diesel engine fire pump set

The diesel engine fire pump set has three perfect starting functions:

1. Manual start function: manual and automatic interlocking can be completed through the changeover switch, and the manual start function can be realized:

2. Automatic manual function: three starts are allowed. If the three starts are unsuccessful, a “start failure alarm” will be issued and the starting state will be automatically exited; after one successful start, the time from starting to rated load is 5-10-15S (depending on the capacity of the unit). );

3. Emergency manual direct start function: when the automatic control device fails, the emergency manual direct start function can be realized.

Diesel engine fire pump set has a complete indication system: ready to start, manual start, automatic start, unit running, unit shutdown, battery charging, overspeed, diesel engine lubricating oil pressure is too low, supercharger oil pressure is too low, diesel engine lubricating oil The temperature is too low, the cooling water temperature of the diesel engine is too high, the battery voltage is too low, the fuel oil level is too low (or lacking), the cooling water temperature of the diesel engine is too low, preheating, and regular inspection.

Diesel engine fire pump set has a complete alarm or protection system: three-time failure alarm or protection, overspeed alarm or protection, low lubricating oil pressure alarm or protection, supercharger low oil pressure alarm or protection, cooling water temperature too high Alarm or protection, low lubricating oil temperature alarm or protection, automatic charging device fault alarm, low battery voltage alarm, high battery voltage alarm, low oil level alarm or protection.