Main Components:

Electric Pumps: Available in various forms including single-stage pumps, horizontal split-case pumps, end-suction pumps, and multi-stage pumps, offering reliable performance and high efficiency.

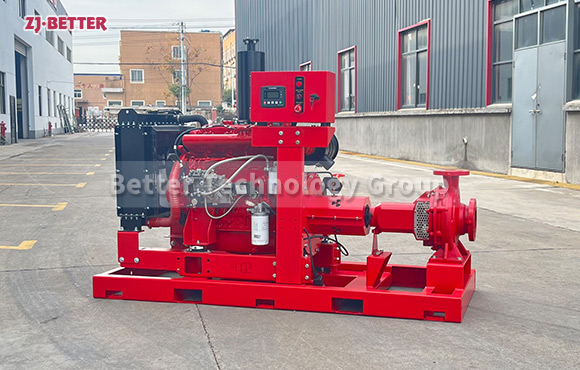

Diesel Pumps: Equipped with the same flow rate and head as electric pumps, these include a fuel tank, water tank, fan, and control panel to ensure effective operation even without a power supply.

Jockey Pumps: Available in horizontal or vertical configurations, these pumps have a smaller flow rate but a higher head than electric and diesel pumps, making them suitable for rapid response in initial fire situations.

Control Panel: Integrated with automatic control functions, it can manage the automatic start and stop of electric pumps, diesel pumps, and jockey pumps, as well as overload and over-current protection.

Our containerized fire pump sets are widely used in large hotels, hospitals, schools, commercial buildings, supermarkets, subway stations, train stations, airports, petrochemical plants, thermal power plants, oil storage tanks, large warehouses, industrial and mining enterprises, and seawater injection, fully meeting the demands of modern urban fire safety.