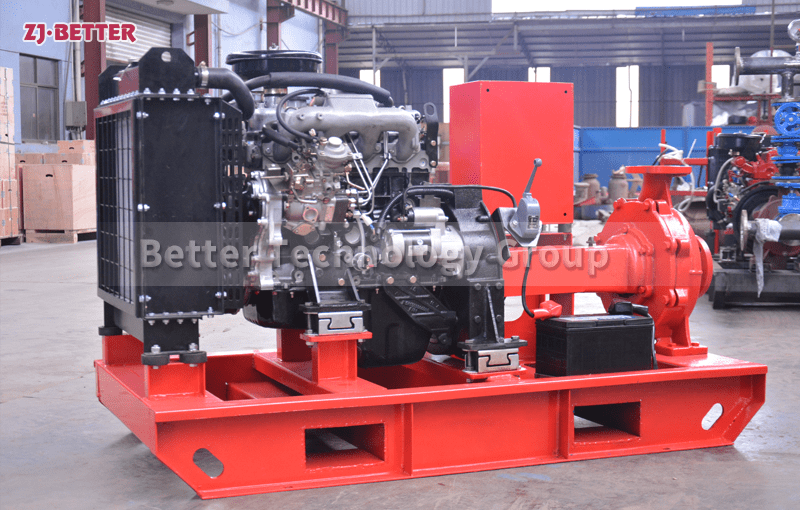

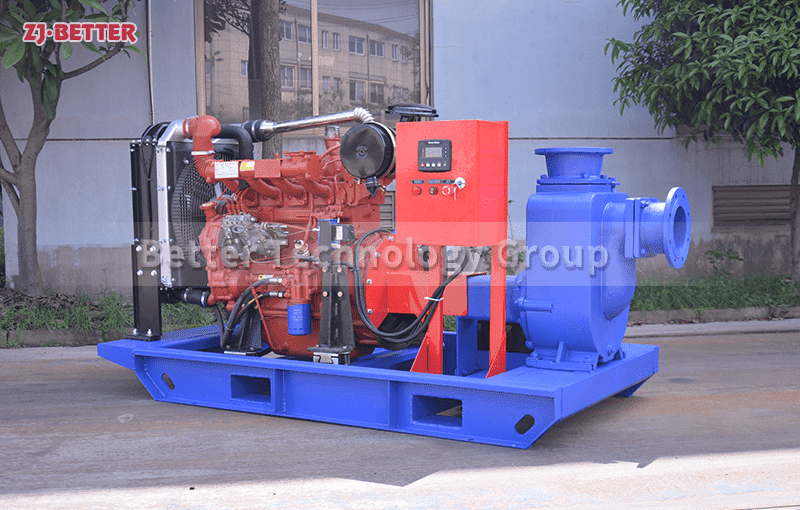

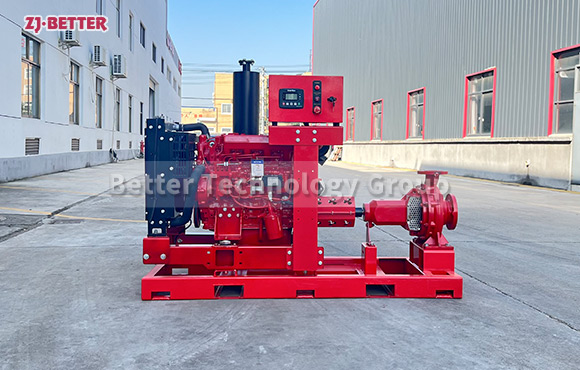

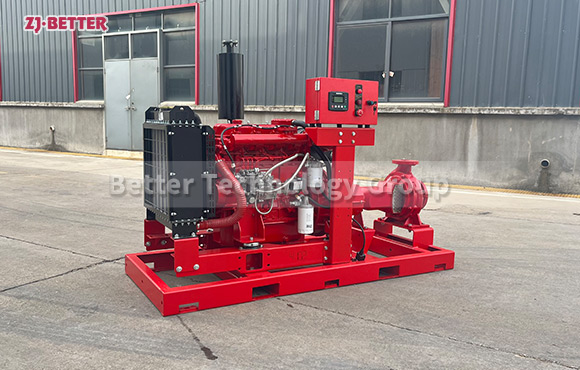

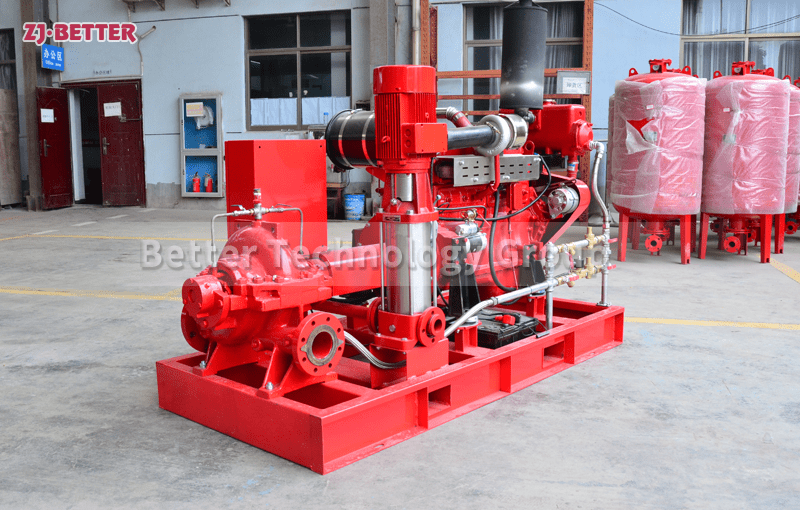

Unit components of diesel engine fire pump

Diesel engine fire pump has high efficiency, long operating life and high reliability. It can be used in independent fire water supply system, some can be used in fire protection and domestic common water supply system, and it can also be used in construction, municipal, industrial and mining, water supply and drainage, ships, field operations, etc.

Unit components of diesel engine fire pump:

The fire pump unit is connected with the fire pump through a highly elastic coupling. The unit also includes diesel tank, cooling water tank, fan, control panel (for automatic unit) and other components.

When it is an automatic control unit, the split diesel engine automatic control cabinet realizes the functions of automatic reset, input, automatic switching, automatic protection and other functions of the system. At the same time, it can also interface with the user’s fire center or automatic fire alarm device to realize remote control monitor.