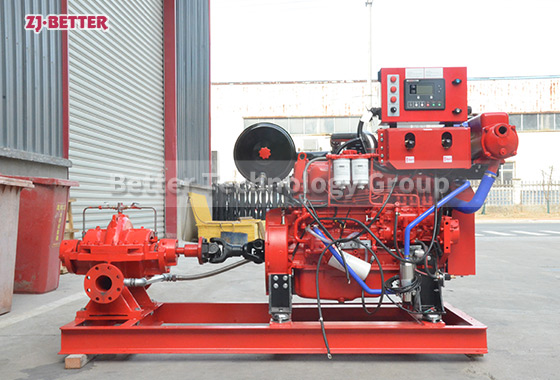

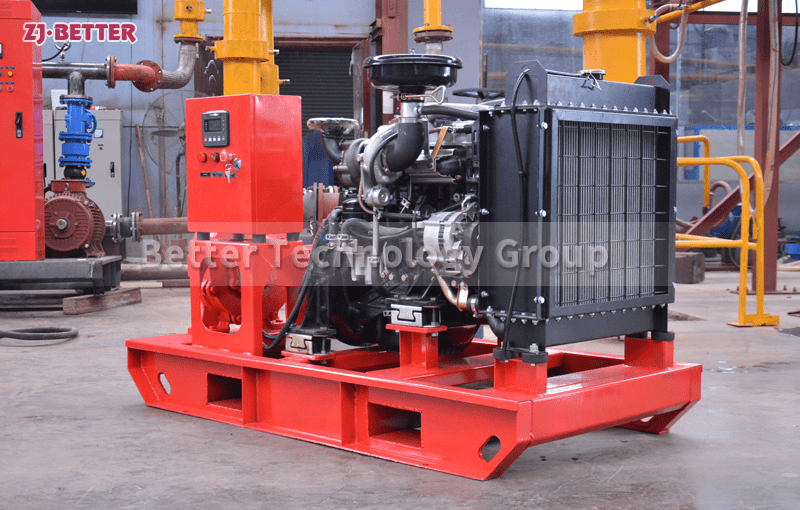

Ventilation system of diesel machine fire pump in use

1. Natural ventilation When setting up and arranging diesel machine fire pumps, it’s first necessary to consider adequately sized ventilation openings and exhaust openings, and secondly, to insure that there’s enough fresh air to supply diesel machine combustion within the temperature limit. In this way, the heat of the circulating cooling water can be taken down by the water force radiator to take down the heat radiated from the face of the unit.

2. Forced ventilation when the natural ventilation conditions can not be met, forced ventilation can be espoused. Inlet suckers and exhaust suckers can be installed at the reflections. The addict specifications and the position of the air bay and outlet in the machine room should be named to give enough cold air for the diesel machine. At the same time, the hot air in the pump room is taken down, and the small air input volume of the unit needs to be about 6- 7 times that of the diesel machine air input.

3. Arrange grooves and seamsters By arranging seamsters around the unit foundation and arranging mountain grooves in the middle of the unit foundation, the purpose of this is to grease the flushing of sewage and diesel oil painting, thereby icing the sanitation of the pump room.

1. Natural ventilation When setting up and arranging diesel machine fire pumps, it’s first necessary to consider adequately sized ventilation openings and exhaust openings, and secondly, to insure that there’s enough fresh air to supply diesel machine combustion within the temperature limit. In this way, the heat of the circulating cooling water can be taken down by the water force radiator to take down the heat radiated from the face of the unit.

2. Forced ventilation when the natural ventilation conditions can not be met, forced ventilation can be espoused. Inlet suckers and exhaust suckers can be installed at the reflections. The addict specifications and the position of the air bay and outlet in the machine room should be named to give enough cold air for the diesel machine. At the same time, the hot air in the pump room is taken down, and the small air input volume of the unit needs to be about 6- 7 times that of the diesel machine air input.

3. Arrange grooves and seamsters By arranging seamsters around the unit foundation and arranging mountain grooves in the middle of the unit foundation, the purpose of this is to grease the flushing of sewage and diesel oil painting, thereby icing the sanitation of the pump room.