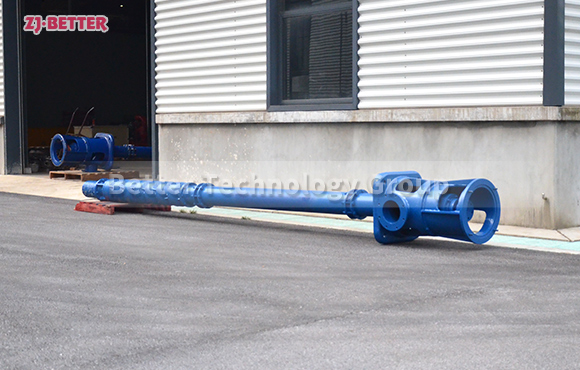

Vertical Pipeline Hot Water Pump (explosion-proof)

IRG series vertical hot water pump are designed according to the unique structure of pipe centrifugal pump.These series pump adopt the advanced fluid model optimized by pump experts. So the pumps have high efficiency and reliability. Some units and components have exported to internal markets and gained good comments from both domestic and oversea clients.

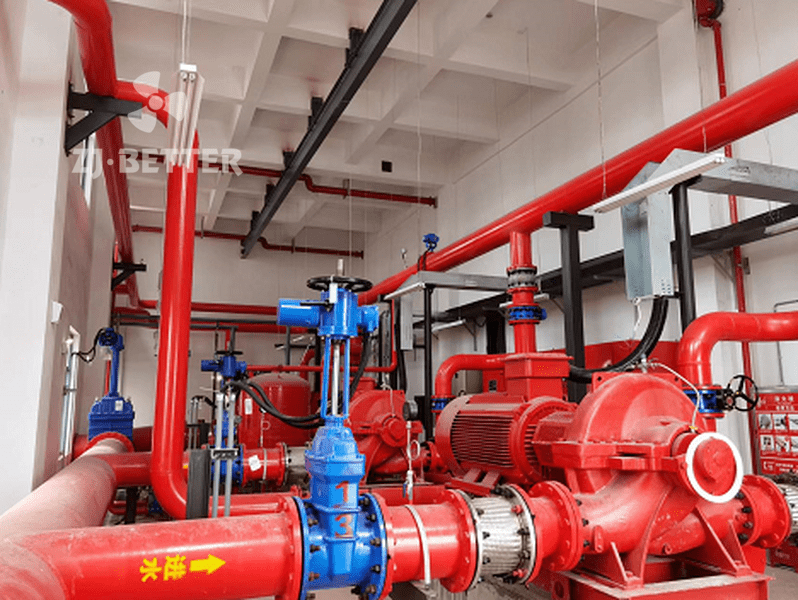

This pump composes of electric motor and pump with pump structure including the pump body, impeller, pump cover, mechanical seal. The pump is single stage and single suction centrifugal and vertical type with inlet and outlet at the same horizontal line and same dia. Able to mount on any pipe line at any place easily and small occupying place.

IRG vertical hot water pump is suitable for metallurgy, chemical industry, textile, wood processing, papermaking, as well as high temperature hot water pressurized circulation transportation of boilers in restaurants, bathrooms, hotels, etc. and urban housing heating circulation pumps. The operating temperature is 99 °C.