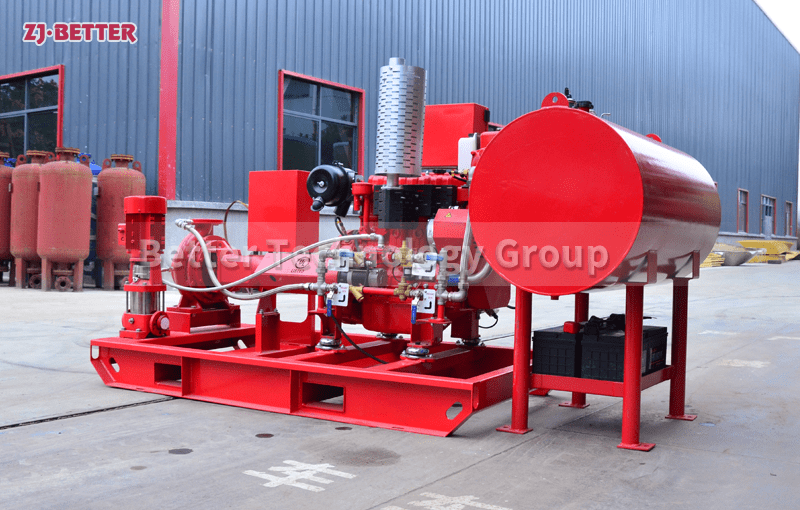

The Diesel Engine Vertical Turbine Fire Pump has a wide range of applications, making it suitable for extracting water from deep wells and hot springs. Whether it’s for firefighting, urban water supply systems, or hot spring facilities, it delivers reliable hydraulic support, ensuring smooth operations.By choosing the Diesel Engine Vertical Turbine Fire Pump, you gain a trustworthy equipment that guarantees efficient extraction of water from deep wells and hot springs.

Vertical Turbine Fire Pumps are suitable for extracting ambient temperature firewater or hot spring water below 100 degrees Celsius from deep wells, rivers, lakes, and seas. They are also suitable for urban areas, factories, sewage, and rivers and seas with significant sand content. They are widely used in industries, towns, oilfield power stations, and agricultural irrigation.