What are the characteristics of diesel engine fire pumps?

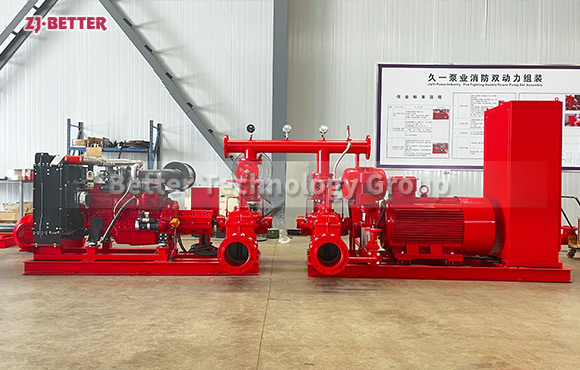

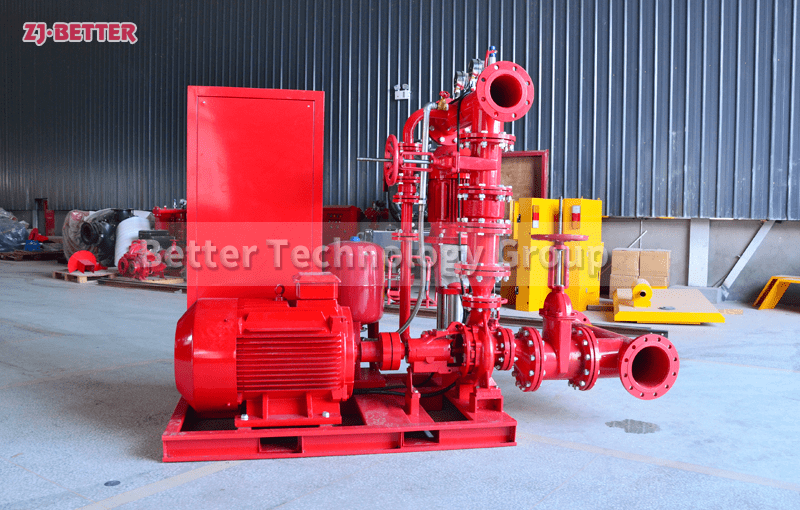

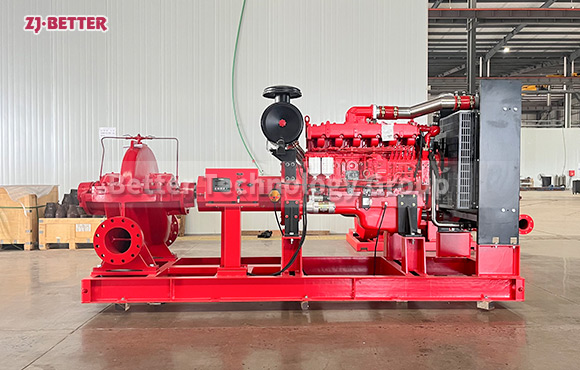

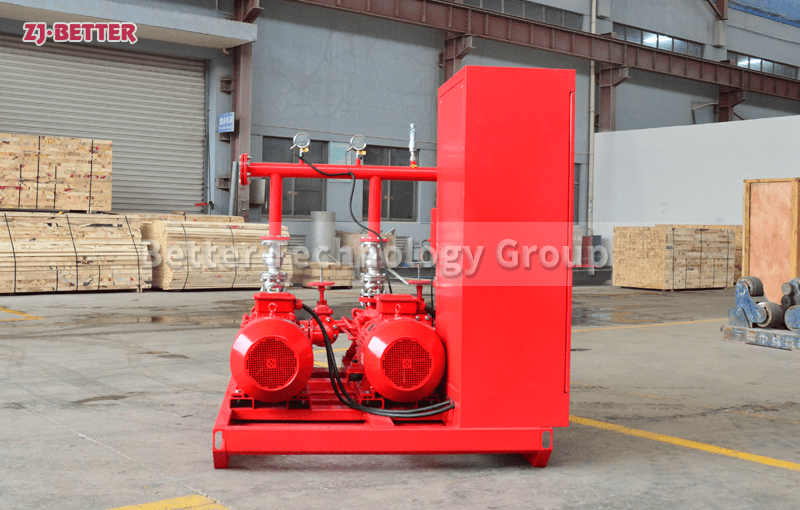

Diesel engine fire pump is a kind of fire-fighting equipment that we often see and use in our life. The diesel engine fire pump has the characteristics of good starting performance, strong overload capacity, compact internal structure, convenient maintenance, simple operation and high degree of automation. It is a very reliable fire fighting equipment.

Main features of diesel engine:

1. Automatic start: The diesel pump unit can automatically start and run at full capacity within 15 seconds after receiving fire/pipeline pressure/power failure/other start signals;

2. Automatic charging: the battery can be automatically charged by the charging motor or diesel engine on the market to ensure the stable start of the unit;

3. Automatic alarm: automatic alarm protection for low oil pressure of diesel engine, high water temperature, etc., overspeed alarm, shutdown;

4. Automatic preheating: keep the diesel engine on standby to ensure emergency operation;

5. Direct connection: The 360Kw diesel pump unit adopts the first diesel engine and pump in China, and adopts the elastic coupling direct connection technology, which reduces the points of failure, greatly shortens the start-up time of the unit, and improves the reliability and emergency performance of the unit.

6. Users can also request to set other alarm outputs;

7. It has the functions of telemetry and remote control.