What are the characteristics of diesel engine fire pumps?

The biggest difference between diesel engine fire pump and electric water pump is that it has its own independent power supply system – battery. Therefore, the start and operation of diesel engine fire pump will not completely depend on city power.

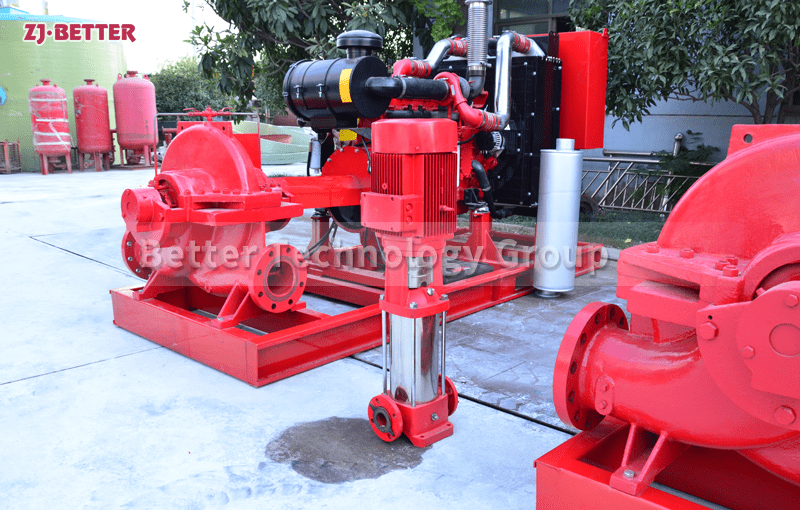

The diesel engine fire pump is usually used as a backup facility, so it will only start automatically when the fire signal comes, and when the electric water pump fails or the power supply is cut off. When it has a device for starting the pump at ultra-low pressure, its matching electric water pump control cabinet should also have a device for starting the pump at ultra-low pressure, and the lower limit of the two pumps should have a certain pressure difference.

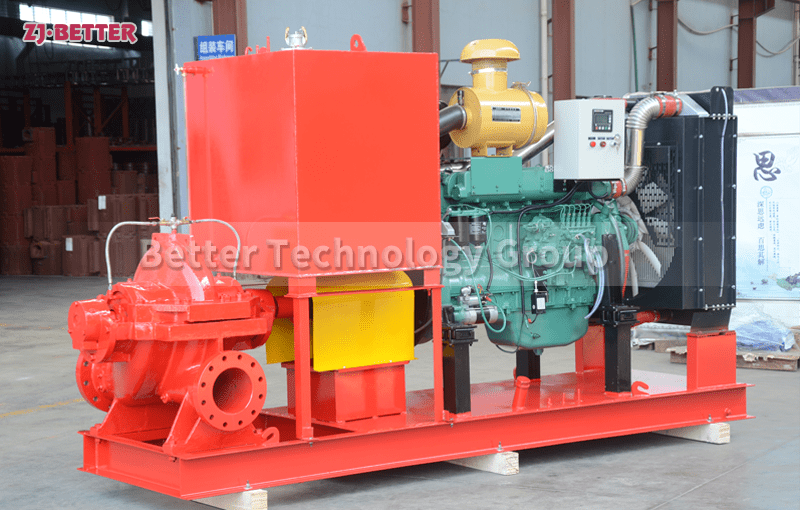

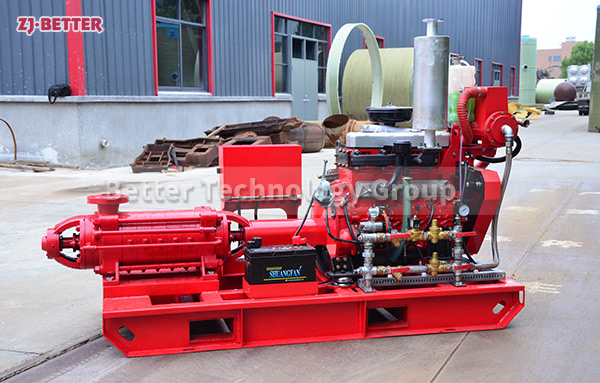

Diesel engine fire pump is simple in structure, reliable in use, convenient in installation, high in efficiency, small in size, light in weight, and has direct drive and variable speed drive. When ordering, the model (power, speed) of the power machine should be specified in order to determine the specifications of the coupling or pulley. Seen from the diesel engine pump to the water pump inlet, the impeller generally rotates counterclockwise. Diesel engine fire pumps adopt advanced air-cooled four-stroke direct-injection diesel engine as the power system, with compact structure, lighter weight and strong power. The main application of diesel engine pump: agricultural drainage and irrigation, industrial drainage and other devices. The diesel engine pump can be selected according to the specific requirements of the head, flow rate and conveying liquid of the place of use.