Home » Fire Pump Set » What are the common problems of fire pump?

What are the common problems of fire pump?

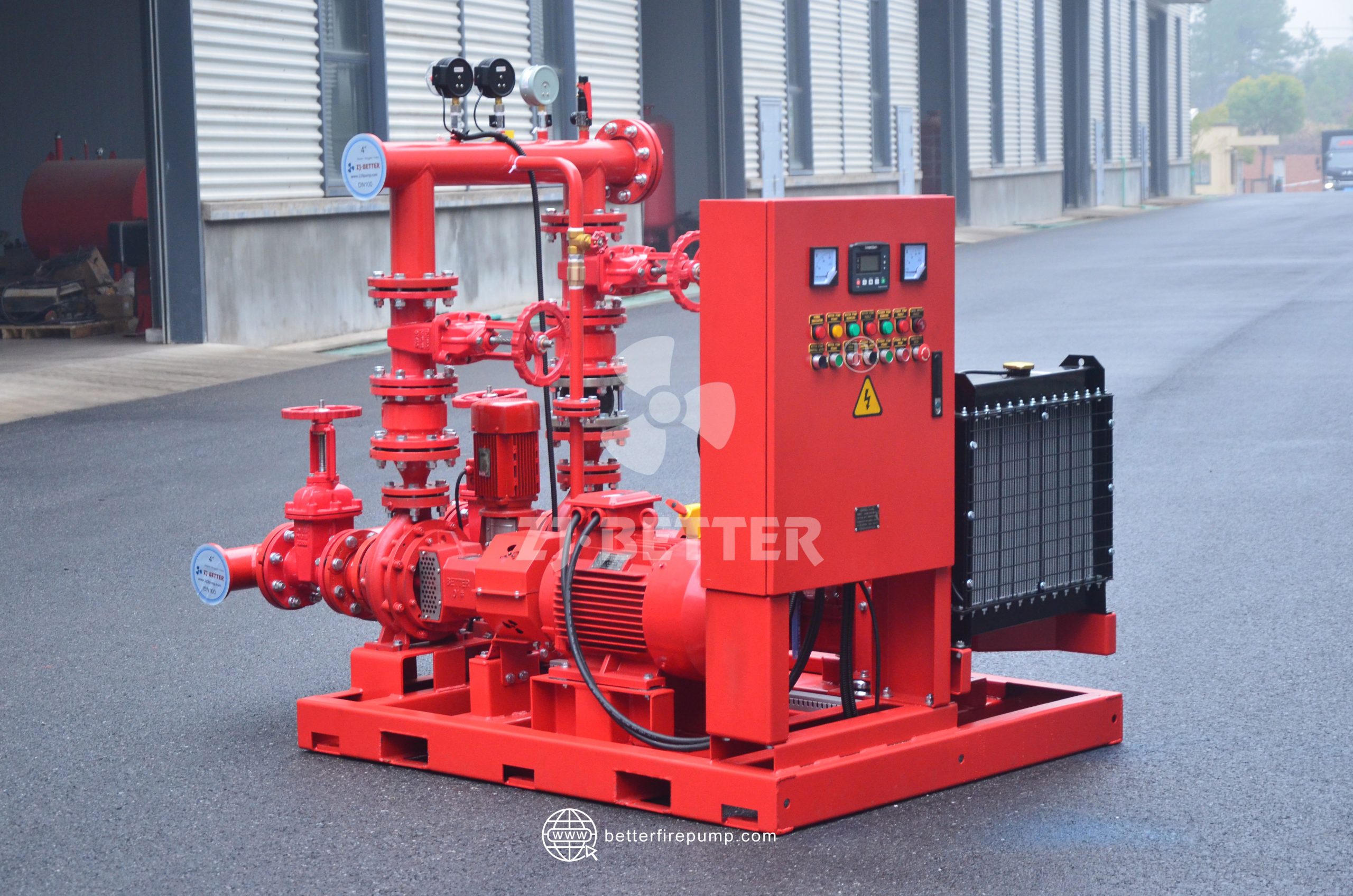

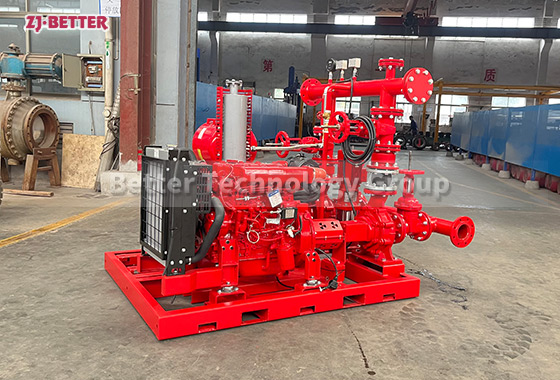

Fire pumps are critical components of fire protection systems, and their reliable operation is essential for effective fire suppression. However, like any mechanical equipment, fire pumps can experience various issues over time. Some common problems associated with fire pumps include:

Contact US

Get Price

Share:

Content

Fire pumps are critical components of fire protection systems, and their reliable operation is essential for effective fire suppression. However, like any mechanical equipment, fire pumps can experience various issues over time. Some common problems associated with fire pumps include:

- Lack of Maintenance: Inadequate or irregular maintenance can lead to various problems with fire pumps. Lack of lubrication, loose connections, and worn-out components can reduce the pump’s efficiency and reliability.

- Cavitation: Cavitation occurs when the pressure at the pump inlet drops below the vapor pressure of the water, leading to the formation of vapor bubbles. When these bubbles collapse, they cause damage to the pump impeller and other components, leading to reduced performance and potential failure.

- Mechanical Seal Failure: The mechanical seal in the fire pump prevents water leakage from the pump casing. Seal failure can result in water leaks, reduced pump efficiency, and possible contamination of the pump’s bearings.

- Impeller Damage: The impeller is a critical component responsible for creating water flow and pressure. Damage to the impeller, such as corrosion, erosion, or imbalance, can lead to decreased pump performance.

- Bearing Failure: Bearings support the rotating shaft of the pump. If bearings fail, it can cause excessive vibration, noise, and potential damage to other components.

- Blockages and Debris: Foreign materials, debris, or sediment can obstruct the pump’s suction or discharge, affecting its ability to deliver water at the required flow rate and pressure.

- Electrical Issues: Electrically driven fire pumps can experience problems with motor starters, electrical connections, or control panels, which may lead to pump failures.

- Overheating: If the fire pump is running continuously at high temperatures without adequate cooling, it can overheat, leading to reduced efficiency and potential damage.

- Incorrect Sizing: If the fire pump is not properly sized for the fire protection system’s demands, it may fail to deliver the required flow and pressure during a fire event.

- Age and Wear: Over time, fire pumps can experience wear and tear, leading to reduced performance and reliability. Aging components may need replacement or refurbishment.

Inquiry

More Fire Pump Set