What are the key factors in designing fire pump systems for oil and gas facilities?

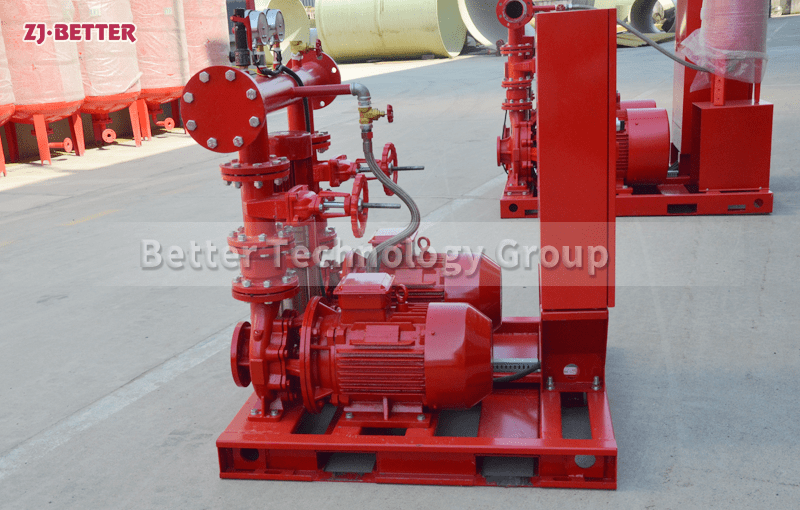

– Handling of Flammable Materials: Ensuring systems are designed to handle and suppress fires involving highly flammable substances.

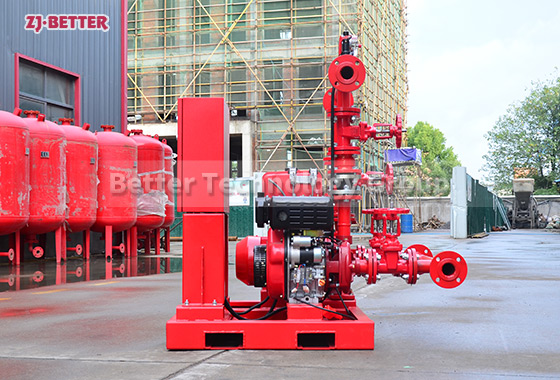

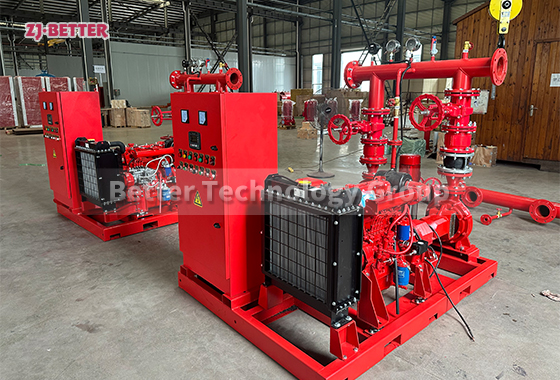

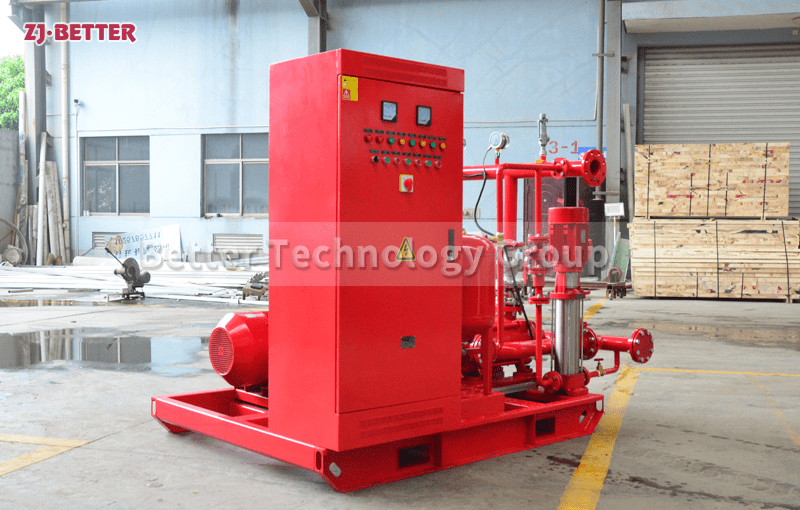

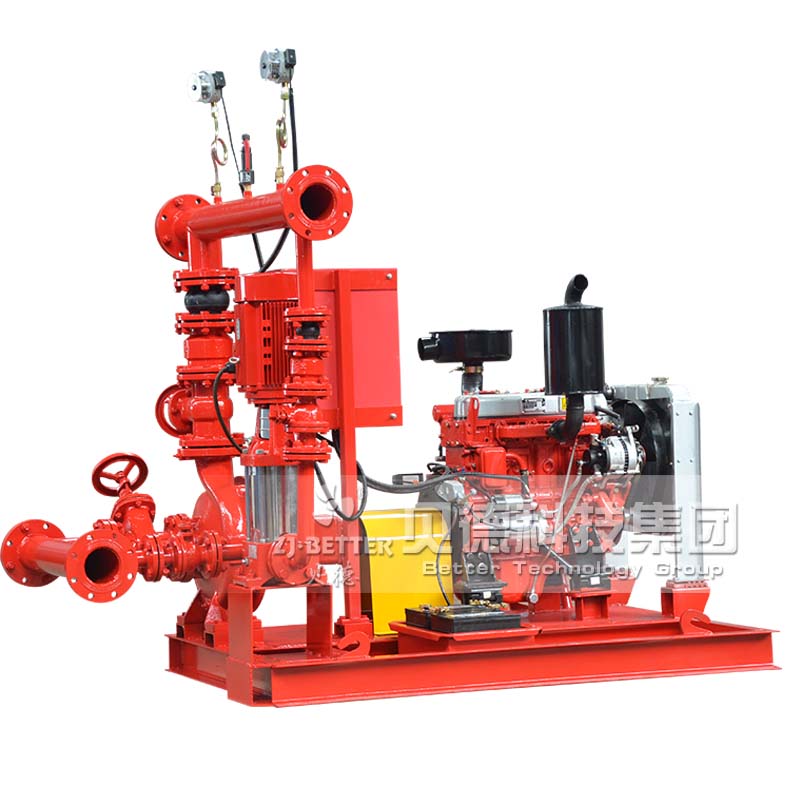

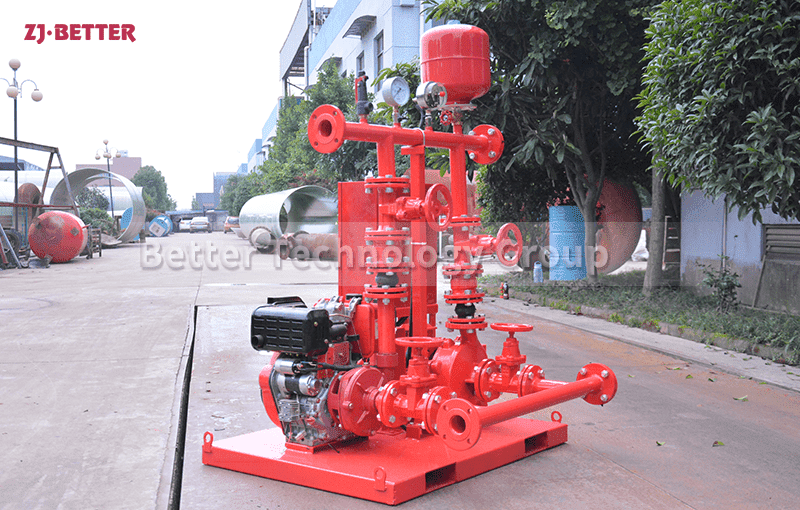

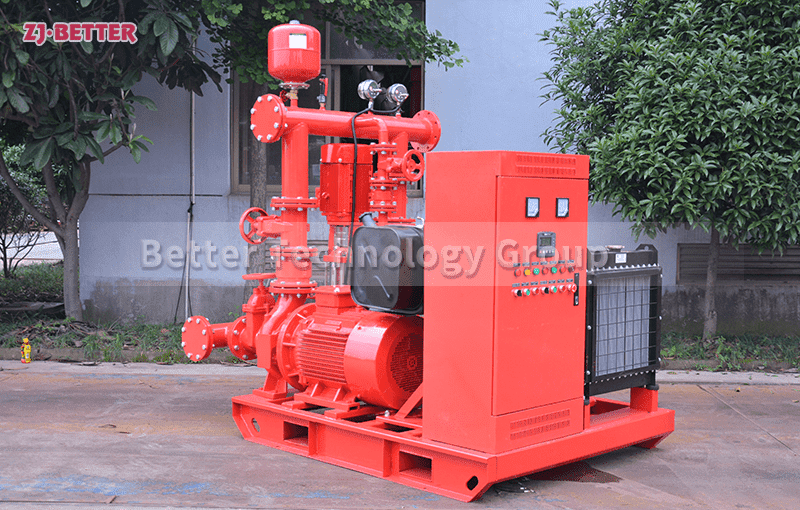

– Explosion-Proof Components: Using explosion-proof components to prevent ignition in volatile environments.

– High Capacity and Redundancy: Implementing high-capacity and redundant systems to ensure continuous operation.

– Compliance with Oil and Gas Safety Regulations: Adhering to stringent fire safety regulations specific to the oil and gas industry.

– Handling of Flammable Materials: Ensuring systems are designed to handle and suppress fires involving highly flammable substances.

– Explosion-Proof Components: Using explosion-proof components to prevent ignition in volatile environments.

– High Capacity and Redundancy: Implementing high-capacity and redundant systems to ensure continuous operation.

– Compliance with Oil and Gas Safety Regulations: Adhering to stringent fire safety regulations specific to the oil and gas industry.