What are the pumps made up of a standard fire pump set?

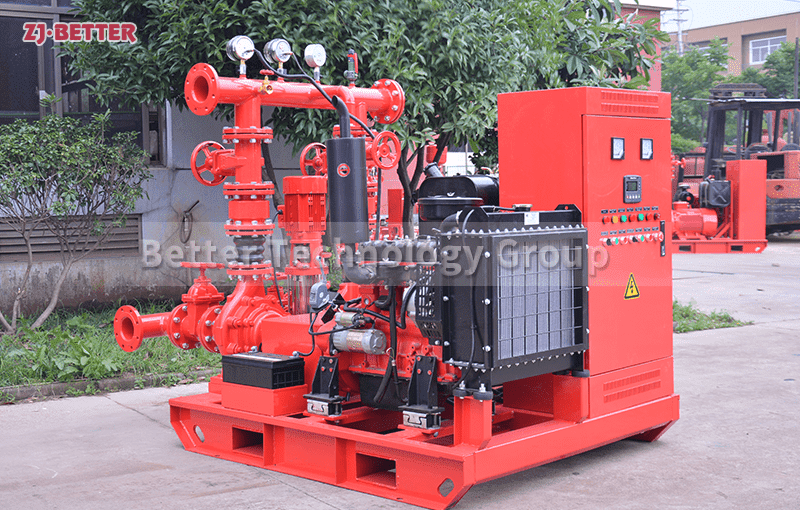

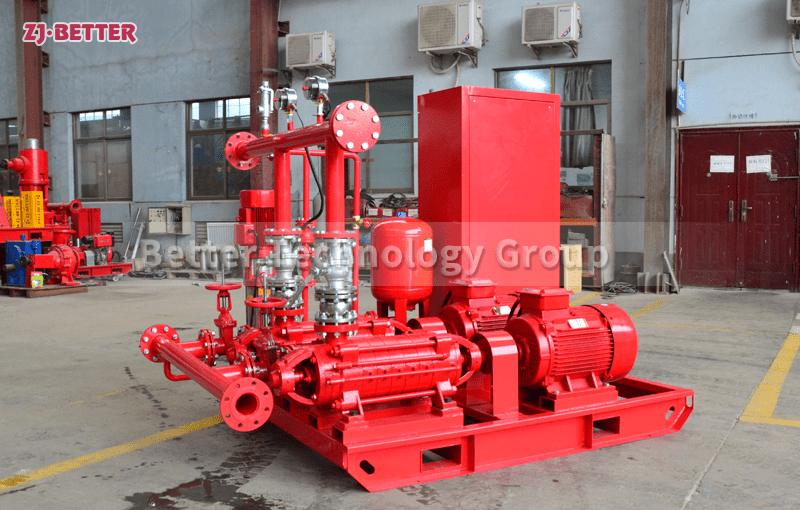

EDJ series fire pump set consists of Electric pump + Diesel pump + Jockey pump and all accessories.

The pressure switch and control cabinet can automatically turn on/off three pumps-the electric pump and jockey pump operate when there is electricity and the diesel pump activates when the power cuts.

Flow Capacity Range:50-5000 GPM

Pressure Range:4-14 Bar

Power Range:4-325 KW

The complete fire pump system consists of the pump, driver, controller and accessories mounted on a universal base. These systems use high quality UL/FM certified components that meet NFPA 20 requirements. All necessary wiring between the controller and the drive is done at the factory before leaving the factory. Automatic exhaust valves, casing safety valves, suction and discharge pressure gauges are installed on the fire pump, and other accessories are installed on prefabricated interconnecting piping required by NFPA 20. Pressure sensing lines are pre-installed on electrical, diesel and NFPA 20 compliant jockey controls.

These systems undergo rigorous performance testing at the factory to UL, FM, and NFPA standards to ensure that the systems perform properly as designed.