What is the difference between a fire pump and a domestic water pump?

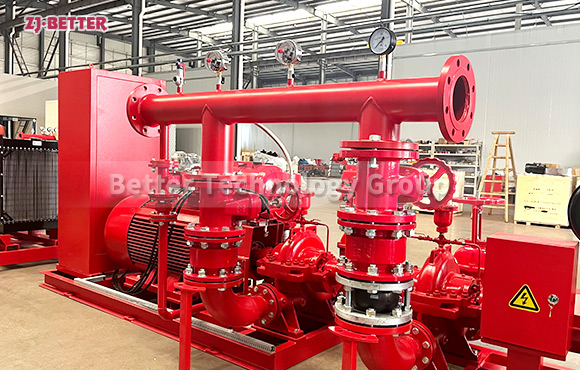

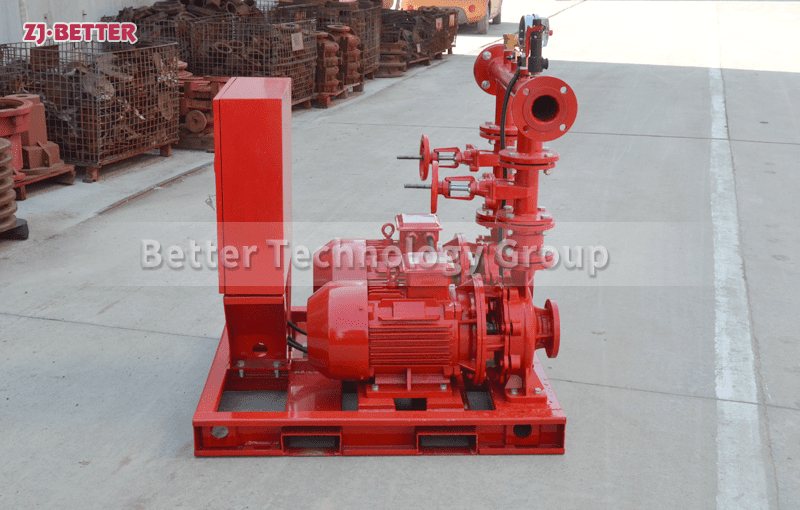

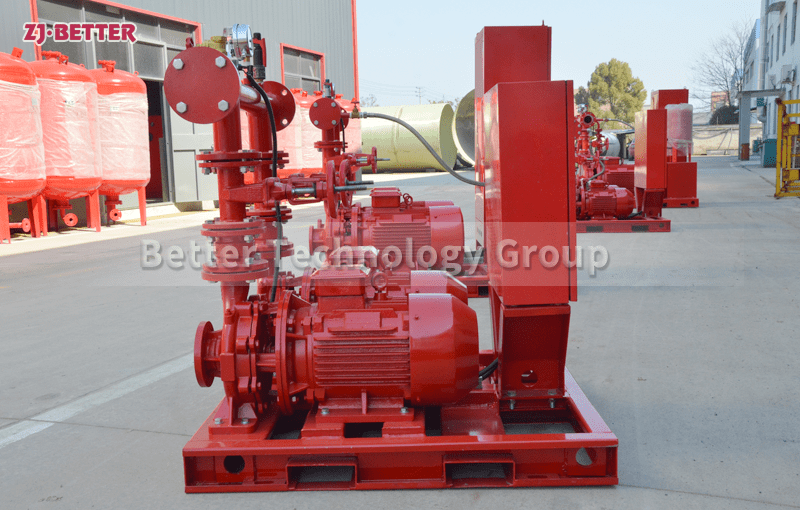

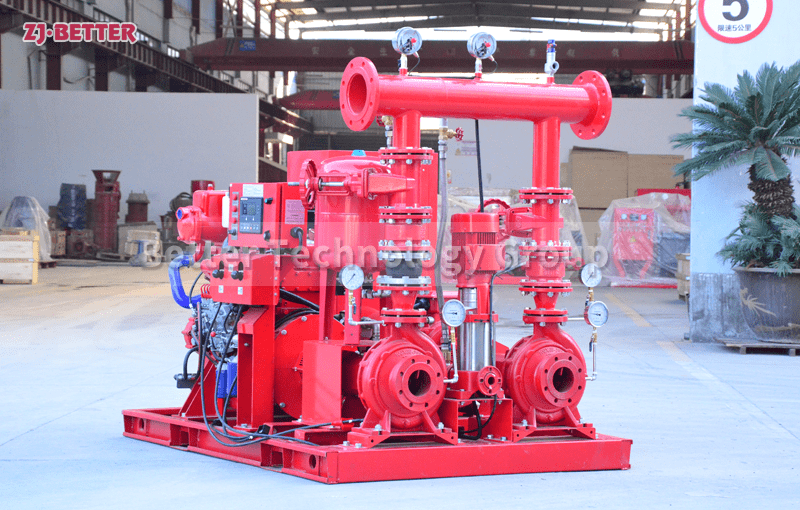

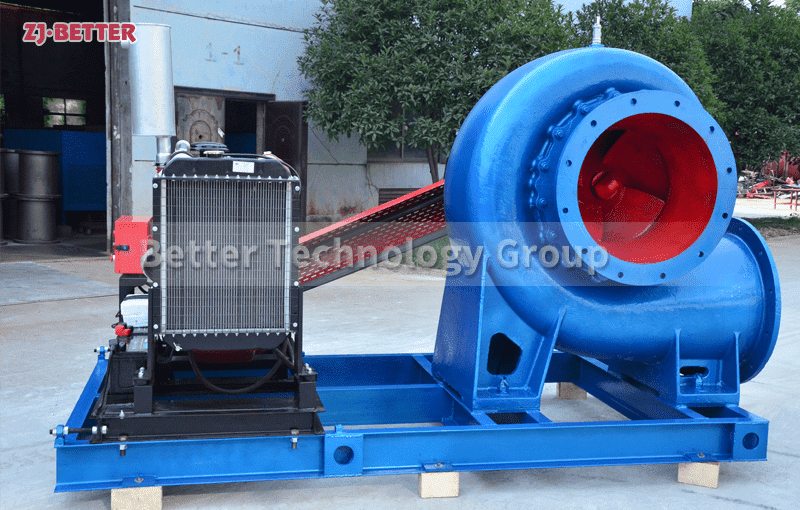

A fire pump is designed to provide adequate water pressure to a sprinkler system during a fire emergency. It is usually powered by an electric motor or diesel engine and is capable of pumping water at a much higher pressure than a domestic water pump. A domestic water pump is designed to provide water pressure to a regular plumbing system for everyday use. It is usually powered by an electric motor and is capable of pumping water at a lower pressure than a fire pump.

A fire pump is designed to provide adequate water pressure to a sprinkler system during a fire emergency. It is usually powered by an electric motor or diesel engine and is capable of pumping water at a much higher pressure than a domestic water pump. A domestic water pump is designed to provide water pressure to a regular plumbing system for everyday use. It is usually powered by an electric motor and is capable of pumping water at a lower pressure than a fire pump.