What’s portable fire pump?

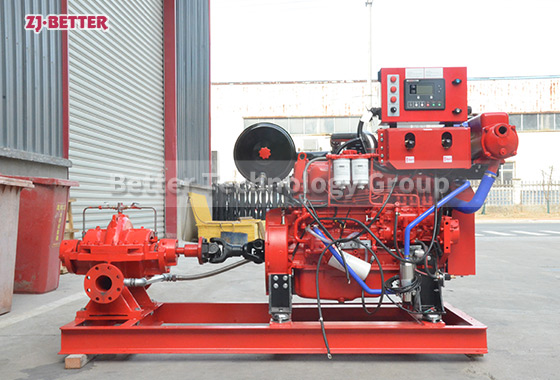

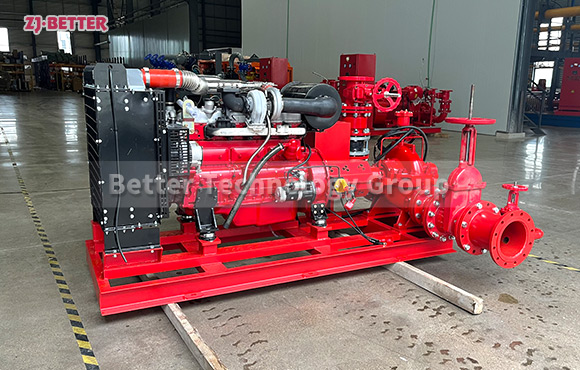

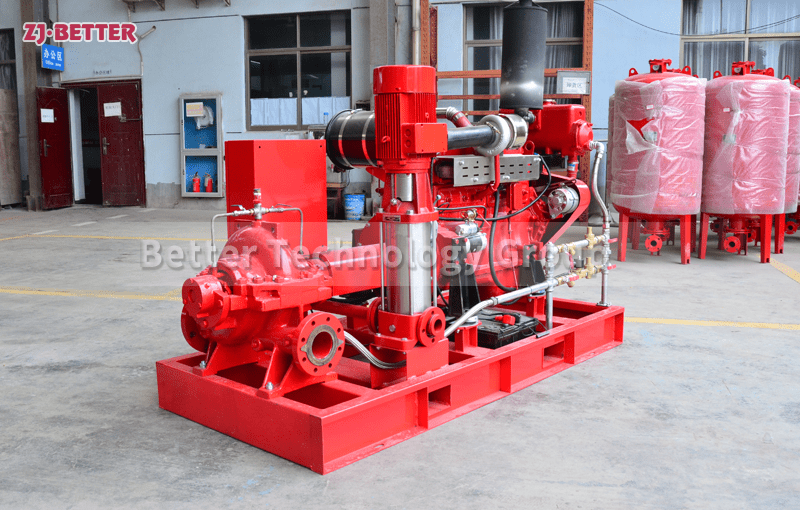

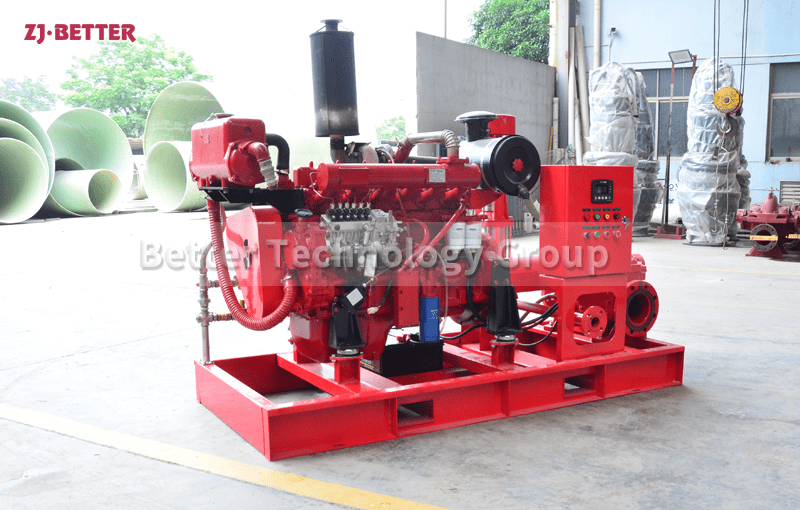

Portable fire pump is mainly composed of engine, water supply system and hand lift. The engine is the power. Most of the engines used in portable fire pumps are automobile engines, because automobile engines have the characteristics of high power, light weight, simple structure, easy to use and maintain, and fast starting. The air supply system is the working part of the portable fire pump, and the hand lift is the support of the whole machine. When using, pull out the handle horizontally to lift the pump.

The portable fire pump is the fire pump which is directly connected with engine and water pump and can be operated by manpower to save common material fire and small oil fire. Because of the advantages of portable and flexible, it is not restricted by traffic, power and regional obstacles, and has been widely used to fight the initial fire in places where roads such as industrial and mining enterprises, warehouses, ports, docks and rural areas have poor traffic conditions and fire engines are difficult to pass or cannot arrive in time.